As you look at the products you manufacture in China, you need to evaluate the risks that something goes wrong.

As you look at the products you manufacture in China, you need to evaluate the risks that something goes wrong.

When it comes to electrical products, one of the major risks is that the supplier uses substandard components in order to earn more profit.

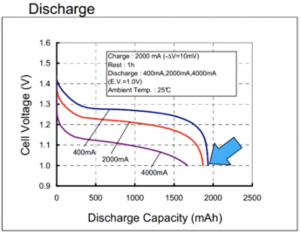

From experience, the risk is particularly high with batteries. The product might work fine during an open-the-box-and-turn-the-product-on inspection but might have a very small capacity.

There are basically 4 options to check the battery capacity in a final inspection.

Option 1: off-site test

All electrical testing labs, as well as our Shenzhen office, have a battery capacity tester. It is one of the most basic testing devices.

Typically, the inspector takes a few samples of batteries and sends them to the off-site testing place. After that, the tester needs to be set up, and it needs to be operated (for several cycles). The point of doing several cycles is to check that the batteries can actually be discharged and recharged, and to have a better idea of average capacity over time.

Option 2: accelerated testing

Ideally, all could be done on site, in the factory, without sending any batteries. But it takes a long time, often 8 hours or more. The inspector often needs to go back (catch the last bus, work on reporting, etc.)

So, why not accelerate it? It would be easy, if not for a non-linear relationship because of internal heating (extra energy loss).

If your supplier has a solid expertise about batteries, ask them what result can be expected if the test is expected to last no more than 5 hours. (Their regular tester can certainly do that.)

Option 3: overtime at the factory

Another simple solution is for the inspector to stay for longer in the factory (which incurs an extra fee for overtime).

But how late? You can ask the supplier how long the test will last if not accelerated.

Option 4: aborting the test

The inspector stays until the time he needs to leave, and records the reading on the tester. This is better than nothing.

—

Can you think of another option?

Obviously, the factory can be asked to keep running that test to the end on their own and to record the result, but it means they need to be trusted… And the point of checking battery capacity is precisely to check if they tried to cheat you…

Lithium-Ion Battery Safety Guidelines For US Imports

Sofeast’s Lithium ion battery safety guidelines for US imports whitepaper is aimed at manufacturers who are producing goods requiring these batteries in China and Asia and seeking to ship them to the USA for sale. In it, we cover everything you need to know about shipping these batteries to the USA, including recalls, product & transport safety, compliance recommendations, and more.

Get your free copy by hitting the link or button below: