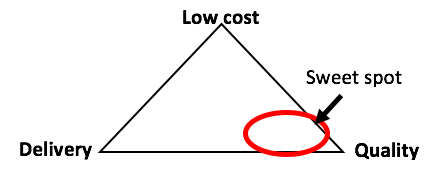

Ideally an importer wants all three of these benefits:

Ideally an importer wants all three of these benefits:

- High quality

- Fast delivery

- Low cost

This might be achievable if you set up your own factory and if your organization is excellent at both engineering and manufacturing. Obviously this is possible only if you purchase one product category (e.g. woven garments, smartphones and tablets).

For all those companies that need to source from several Chinese manufacturers, a tradeoff must be made. A strategy needs to be put in place to support the business’ objectives.

Here are a few examples.

Cost first, then delivery

Most promotional items that are given away have low quality requirements. Instead, they have non-negotiable timing requirements and often need a low price.

The adequate sourcing strategy for these companies is usually to put many suppliers in competition and to move ahead with production fast (without going through a tough qualification process). Orders are often one-shots. The main challenge lies in managing the supplier’s behavior.

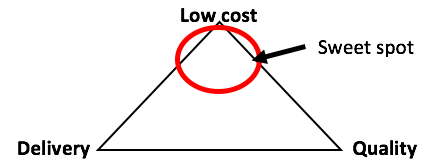

Quality first, delivery distant second

In contrast, aerospace-grade products are often extremely expensive because companies like Boeing or Lockheed Martin get awarded contracts that allow for high component prices. Complying to extremely tough specifications is by far the most important criterion. The pool of specialized suppliers is very narrow.

By the way, aerospace is an interesting example of quality overshoot. Space Ex is also building rockets but has been incorporating many consumer electronics components.

From what I read, NASA challenged them numerous times about the reliability of a part, and Space Ex has had to run tests that sometimes demonstrated the superior reliability of the much cheaper parts.

Cost, cost, cost

Some markets are nearly all about cost. If you sell basic cotton underwear to discount retail chains, you will need to find the cheapest source — probably around Quanzhou in China or around Dhakka in Bangladesh — that meets some minimum standards about on-time shipments and about cost.

A bit of everything

Other distribution channels want all. If you sell to a wholesaler that sells under their own brand to supermarket chains in Western Europe, that company will need a certain quality standard, a relatively low price, and few shipment delays.

They typically need to work with stable suppliers in order to ensure a certain level of reliability, and keep constant pressure on price.

—

I could go on and on. But the logic is always the same. Importers should consider their market’s dominant requirements before deciding on a procurement strategy.

I see companies that serve their customers reasonably well but take actions to lose their whole business’ balance. For example they are doing fine on quality and delivery — which their customers demand first and foremost — but they try to find cheaper suppliers. That might be necessary if production costs are rising and/or selling prices are going down, but don’t forget to re-assess your strategy as a whole.