I work in a quality control firm and we work a lot for the textile industry, which has its own jargon. For example: “CMT” (Cut, Make & Trim). What does it mean?

If you buy any sewn products in Asia, read this post and you might learn something relevant about your suppliers.

What is Cut, Make, and Trim (CMT)?

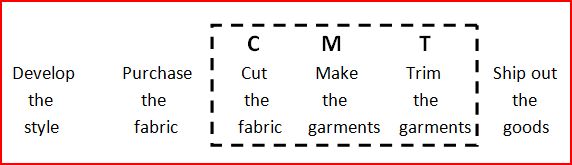

Cut, Make, and Trim production is where an apparel factory takes your designs and produces them following three stages. ‘Cut,’ where the material is cut to your pattern, and made ready to sew, ‘Make,’ where the garments are sewn together and created, and ‘Trim,’ where the garments are finished, any threads and small imperfections are removed and final QC and packing occurs.

Why not watch the presentation of this blog post?

And you can also get the presentation for later here, too!

Quick overview of the steps of garment production:

Basically, there are three ways suppliers can be organized:

- Finished product sourcing: an intermediary gives the order to a factory (or splits it into several factories) under FOB terms. This is what most trading companies based in Hong Kong do, and importers often wonder what value these middlemen add to the buying process.

- In-house production: a factory gets an order and makes the goods in its workshop. Most buyers expect this to happen when they “buy direct from the manufacturer”. But, quite often, it is NOT what happens (see below).

- CMT purchasing: the supplier keeps the development of new styles and the materials under his control, and outsources the labor-intensive jobs (cut, make/sew, trim / final QC, and pack). How often does it happen? It is difficult to estimate, but I guess at least 25% of garment production is managed under CMT terms in China.

But why outsourcing only certain activities when following CMT terms? And which ones?

Let’s simplify the steps of the production of a batch of garments.

- Some samples are made to match the customer’s design and get the order.

- The patterns designed in the sampling phase are used for consumption calculations and pricing.

- The fabrics, accessories, and packing elements are purchased.

- The fabric is cut and then bundled by style, size and color (that’s the CUT).

- The different sewing steps are performed in a workshop (that’s the MAKE).

- The finished products are trimmed, checked one last time, and packed for shipment (that’s the TRIM).

Why keeping certain steps in house?

Suppliers try to keep their hand on development and purchasing:

- Making patterns and samples. It is critical for getting orders. A small sampling room with a few good technicians is enough.

- Purchasing materials. The consumption is calculated with patterns, and buying the fabric is the most important expense.

One step is usually outsourced under CMT terms: “cut”. It requires a large room, some specialized equipment, and a few experienced technicians. However, if properly managed, the benefits of keeping cutting in-house can be huge.

First, fabrics and accessories can be controlled as soon as they are received, and before it is cut. I am certain that, when the “cut” job is done by the sewing workshop, these inputs are checked in a small minority of cases. Why should the workshop care about it?

Second, the unused fabric is kept aside (the leftover of fabric is sometimes the main source of profit on an order, and of course the unused fabric is never declared by the workshop when cutting it subcontracted).

Third, an investment in automatic cutting equipment can help save on fabric consumption. The payback period might be less than a year!

The last two activities are always subcontracted under CMT terms:

- The “Make” (i.e. sew) job. Operating a workshop is a recurring cost for a fixed capacity. Outsourcing this activity means your production capacity has no limit! And sending a sample to several workshops is enough to find “the cheapest needle”.

- The “trim” job, usually including final QC and packing. If an external workshop sews the garments, it should also trim the threads, pack the goods, and repair the workmanship defects.

Hopefully, a few inspectors are sent during the “MAKE” step to avoid quality disasters.

What are the risks of outsourced CMT for the importer?

The main downside of this supply-chain structure is that the workshop is the weakest element of the network. It is replaced quite easily. It has to bid a low price to get business, so it needs to rush production to make a small profit. In China, 99% of garment factories have the same organization, so lower costs are only achieved with unskilled labor, long hours and minimal QC. Exactly what buyers should avoid!

Actually, the sewing workshop should be at the center of the supply chain:

- Where do most quality problems come from? From the workshop job (either because of poor attention to quality or because of poor communication of the buyer’s requirements).

- Where do last-minute delays come from? From the workshop (because of bad planning, of an order rushed for another customer, and/or of re-work due to poor quality).

For further reading:

- Who should buy the materials when production is outsourced?

- Why the garment industry is different

- Complex supply chains in China

- Chinese suppliers and subcontracting

- Quality Control basic concepts

Are you trying to find a manufacturer in China who is well-suited to your needs and can also deliver on their promises?

Sofeast has developed 10 verification steps to help importers find the right manufacturing partner in China. They’re shared in this FREE eBook: “How To Find A Manufacturer In China: 10 Verification Steps.”

It covers:

- Background checks

- Manufacturing capabilities

- Quality system auditing

- Engineering resources

- Pricing, negotiation, & contracts

- …and much, much more

Just hit the button below to get your copy and put yourself in a great position to get better results from Chinese manufacturers who supply your products:

20 Responses

we are about to set up a cmt center that will benefit rural sewing groups, i need as much information as possible about setting it up, its value.

Hi Buli, that seems interesting. Where are you doing this?

Basically you’ll need good technicians (especially for preparing patterns and for cutting the fabric), and they should help you work out all the details.

Good luck with your project!

Asalam-0-Alikum …

We are dealing in with Garments and Textile Stiching Business in lahore , Products : T-shirts , Polo Shirts , Trousers , Hoodies , Female and Children Leggy and any other Garments knitting or weaveing for Mens, Womens and lady and Textile Products like Bed Sheets , Pillows and etc etc ,according to requirements or on order or on C.M.T Basis also .

No Compromise on Quality and Deleivery Time .

for More Details please Contact :

awais ali International

awais ali

92 0321 4097984

I’m in Fiji just looking for Cmt garment just to supply the staff or to kept staff in the factory.

HI esther ho mny your line and Im looking cmt now delivery is July 22 bby shirts ith snaps on bttom 3 pcs and qty 12000 pcs and blouse 12ooo pcs same thing cmt delivery july 16 kindly contact to me no jenffer 082111799154 or 021-92232480 email hanahansjustin@yahoo.com Please rvrt and thnks

Hi Mike please call me yah now I need ther space asap bby and blouses and other styling 082111799154 jennifer thnks

we are s small company call Cut Make and Trim locaket in scarborough ont

Mike, What’s the name of your company? Can you flat seam stitch on 4 way stretch fabric?

I am Taufiq from Tangerang Indonesia. I am doing CMT. I am looking for a Bussines Partner.

We are children´s clothing manufacturers in Bucaramanga Colombia. We use to work CMT prices for some of our customers. However we normally supply linings, buttons, thread, elastics and some other raw materials different than the main fabric. In that case, still is CMT?

You are working in a way that is hybrid… You can still say CMT, I think.

It is called CM (Cut Make). Hybrid should be if they supply the thread aswell.

am a qam In one korean factory, am agree with you… all problem there are a cause’s and that causes need to eliminate of every factories before getting an order.and place to other factory.

I am a sewing thread manufacturer, we have good polyester and cotton sewing threads for light and heavy garments, we use oek certified yarn and fiber we also exports in several countries, do contact us for any information ati_thread@msn.com

Cell # +92 3452763557

Skype: talha.ismail91

usha : am garment manufacturer, said suggestion great, though need to improve few more points

Hi Renaud,

Is it possible for you to advise me about how to accurately calculate the price you would charge a customer for cut, make and trim if you also supply the fabric and other materials to be used.

Thank you!

Unfortunately I don’t know how to do that.

I have a pretty good idea, I only need to double check. Thank you anyway, but if there’s anyone out there that can comment on this I would really appreciate it!

hi

i have run a small but effective garment unit in india. by effective, i mean making garments without the regular pitfalls of quality issues, delayed deliveries etc.

the idea is to plan well & execute well. if you have the right mindset & can inculcate the same mindset for quality to your team & vendors, then quality will never be an issue.

even though we had a small factory, we would always start every style from scratch, with proper time spent on the first cuts, patterns perfection, for bulk runs. most patterns are finalised as soon as the size set is approved, without realising the difference in making 3 garment in 3 hours & making 10000 in 10 days. the speed of the machines & the finish required for bulk runs are totally different. patterns & the cutting really need to be monitored well during a strict pilot run before embarking on bulk production.

all garments of the same size must fall on each other without any shadow. & i am talking knits, which are really critical to manage if left to themselves.

regarding the cost calculations – basically calculating the CM costs should involve the time & margins. so if your factory can produce x number of garments in n number of hours, use simple maths to arrive at the cost. the market works on this same formula. some factories might be a little higher, some a little lower depending on the quality parameters perception of each. & if your costs are way different, then there’s something wrong

Thanks for sharing your experience, Pravin.