If you have been designing a new product and you plan to have it manufactured in China or another Asian country, when and how should you contact a manufacturer, and what should you do first?

- If you contact them too early, the scope of work all the way to production is quite fuzzy, and there is a high chance they give up on the project when a lot of obstacles appear.

- However, if you take into account the realities of manufacturing too late, you might have to take a few very painful steps back, making product design changes, when you thought you were so close to production.

First, make sure your product design is mature enough

A manufacturer’s business model is to… manufacture. The dominant model is to make batches of what is called “mass production”. Product design is not their main focus and usually isn’t what they are best at.

That’s why I suggest you try to make some progress first without involving a manufacturer:

- Get in touch with an industrial designer

- Hire an engineer if needed, or work with an engineering firm

- As you make some progress and you start to put prototypes together, try to get a “Design for China Manufacturing” review done by a company that is familiar with manufacturing processes.

I wrote more about this in Don’t Send Immature Product Designs To A Chinese Manufacturer:

The basic information any manufacturer will need [for an electronic product] is:

- A detailed description of features

- List of components, with specifications

- Product architecture (how components are connected together)

- PCB schematic

- A look-alike and work-alike prototype

- Testing stations

- A timeline and volume projections

Some companies think in terms of technology readiness levels. Before TRL 7, it is probably too early to involve a manufacturer.

Make sure you have a plan for the necessary steps all the way to mass production

Do you plan to “just get a prototype, and then go into production”?

That may be fine if the product is very similar to what that factory is already making. You want a new shade of blue, they make a prototype in the right color, you approve it, and they can keep using their usual approach.

If the product you are developing is new, though, it’s very likely that the manufacturing and testing processes need to be adjusted and validated before you authorize the factory to go into production.

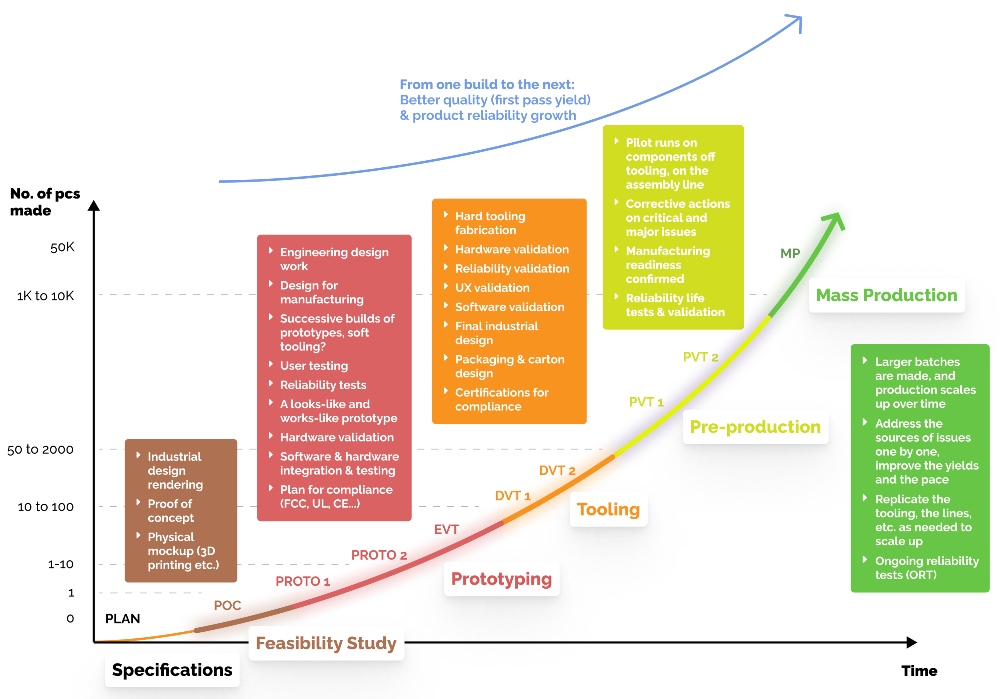

For electro-mechanical goods in general, here is what the 6 phases (which we call specifications, feasibility study, prototyping/EVT, tooling/DVT, pre-production/PVT, and mass production) typically include.

I wrote about this in these articles:

- Going from 1 Prototype to Mass Production directly is Dangerous

- New Product: How Many Builds before Mass Production?

- Planning for Quality & Compliance at the Product Design Stage

Do not give all your design files away without a few precautions

When the time comes, prepare a product design package that includes the information the manufacturer will need to know.

However, you should not send that package to 10 or 20 suppliers that you found on Alibaba.

- First, screen them. Get down to 1 or 2 suppliers that you are comfortable with.

- Second, get them to sign an NNN agreement that is enforceable in their country. That’s a basic precaution, don’t skip it.

(I’d add that, if you contact Chinese manufacturers, most of them, unfortunately, don’t care about the NNN agreements they have signed, and there are all kinds of leakages of information. Hence the need to qualify them carefully first, before sharing design files.) - Third, don’t get too fixated on the RFQ and the price — a bad manufacturer that has a price 10% lower might cost you 3 times more, all things considered…

To summarize

Starting to engage a manufacturer in a country like China, India, or Vietnam, before your product design is firmed up, is dangerous. Good manufacturers will not be interested, since they know the scope is not clear and it will take a lot of management time. Bad manufacturers might attempt to steal your design work and make your product without engaging you…remember these two points before you contact them.

Disclaimer

We are not lawyers. What we wrote above is based only on our understanding of legal requirements. QualityInspection.org does not present this information as a basis for you to make decisions, and we do not accept any liability if you do so.

Are you wondering how to find a manufacturer in China who is well-suited to your needs and can also deliver on their promises?

Sofeast has developed 10 verification steps to help you find the right manufacturer. They’re shared in this FREE eBook: “How To Find A Manufacturer In China: 10 Verification Steps.”

It covers:

- Background checks

- Manufacturing capabilities

- Quality system auditing

- Engineering resources

- Pricing, negotiation, & contracts

- …and much, much more

Just hit the button below to get your copy:

Excellent advice as always, Renaud! I would like to offer comments/ further suggestions on two points that may be useful to readers. These apply to “mass market” oriented products, not single pieces or 25 piece lots.

First, I don’t think you can overestimate importance of the “pilot run/manufacturing readiness” stage. Realize that by this time you “should” have the entire product design proven out. Many suppliers will miss this point.

The goal of this stage is to prove out the manufacturing process. By way of illustration, in automotive we start with the following guidelines: Produce at least 300 pieces, on the production tooling in the production environment. (Quite a few of the electronics suppliers I have seen have an entire separate team to do pilot/first article production. This doesn’t meet my rule of production environment, and maybe not even production tooling and equipment. Let the supplier follow their process and then add this step as the first stage of their “mass production”.) Take 5 or 6 samples AT RANDOM and check them for compliance to the drawings/specs. EVERY SINGLE ITEM OF THE SPEC. Yes, I am serious. Now you will obviously make some compromises here. I have worked with the production of USB cables where 100% validation of compliance costs $10,000 or $20,000 to do 1 piece. You had better at least have a good workaround. Finally do a formal corrective action for every issue found. As a bonus you get some samples to use for market testing, etc., assuming all has worked well. (Yes, you will need to pay for them, that’s only fair!)

Second, I fully agree that you should be very cautious about releasing your IP to manufacturers. Eventually some of it will leak no matter what. Your actions can make the difference between a slow leakage vs. a dam breaking. Some techniques I have used… first, do whatever you can to pre-qualify the suppliers. Don’t just send the bid pack out willy nilly. Have a short summary with as few technical and market details as possible first. Then with those suppliers who seem reasonable, make up a doctored copy of the spec. Identify several items on the design that won’t matter (at least, much) for pricing purposes…. but change them so that the product won’t work. Use these for quoting. When they get around to others who might try them, it will serve them right! THEN MAKE SURE THAT THE SELECTED SUPPLIER GETS THE RIGHT SPECS, AND DOESN’T HAVE COPIES OF THE FAKES IN USE!!! If you really want to play detective, put at least one unique tweak for each potential supplier… then you’ll also be able to tell who the bad apple was. (Truth is I’ve never done this step though I have thought about it! I learned this many years ago from a publisher of reference books — specifically, what in the US are called “blue books” — estimates of current market value of used cars. If someone copied one and successfully resold it, they could always claim that they had come up with the same info independently, BUT… then why did you value the 15 year old 2005 Toyota sedan at twice the actual value… at EXACTLY the number we published?

Anyway, thanks as always for a well done post. Wish you all the best!

Brad