If you purchase products in China, you have noticed that price increases are often presented as a law of nature. This is one of greatest frustrations of importers.

If you purchase products in China, you have noticed that price increases are often presented as a law of nature. This is one of greatest frustrations of importers.

Fortunately, there are solutions. If you need lower costs, you can follow two approaches that I detailed below.

1. Traditional sourcing

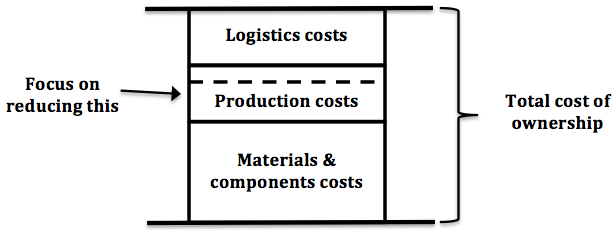

The focus is on eliminating middlemen and compressing the factory’s margin, in order to reduce the FOB price.

It can be achieved in various ways:

- Gathering more volume on fewer factories to get better pricing (it doesn’t always work)

- Working with smaller factories that have lower structure costs, and then monitoring quality very closely

- Chasing the lowest wages around Asia (but this is not always a source of savings, especially if these new manufacturers need to source materials from China’s coastal areas)

- Paying Chinese suppliers in RMB as I described here

Other, more advanced methods are also available to reduce production costs:

- Redesigning products to make them easier/faster to manufacture

- Semi automating operations that are currently manual, to fight the rise of labor costs

- Putting a lean manufacturing organization in place to reduce up to 50% of variable costs

- Improving processes to target and eliminate a source of high costs on the buyer’s side (e.g. missing parts)

Unfortunately, all these initiatives only attempt to reduce production costs. Yet there are many other opportunities…

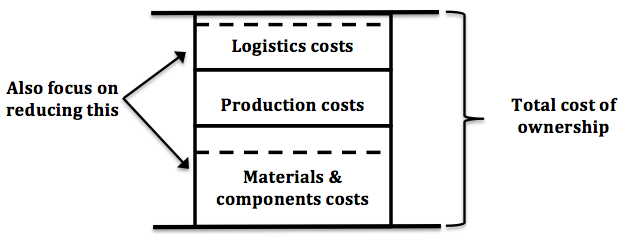

2. “Total cost of ownership” focused sourcing

This approach addresses the two other big sources of costs: materials & components, and logistics.

Here are a few ways it can be achieved:

- Negotiating directly with material suppliers

- Standardizing components of several products, in order to make the second-tier supplier’s work easier

- Producing closer to the final market in order to compress the time to market, to expedite fewer shipments, and to reduce the need for stock

- Redesigning products so that they consume less material and/or cheaper material

- Redesigning product and/or packaging to save on logistical costs

- Consolidating shipments from several suppliers

- Optimizing distribution routes from warehouses to stores

I hope some readers can suggest other cost cutting initiatives?

Very true, And the opportunities in material and component cost (incl. redesign or use of alternative parts) are increasingly important especially for more complex products (high tech, industrial, renewable …).

This is where the real sustainable cost reductions are, even though it requires much more work and better organization then just a hard ball negotiator.

Yes I agree. It represents more work, but it brings more long-term benefits. A Chinese supplier can be banged on the head a few times, but in the long term he will either find “solutions” to increase his margin or he will stop the business relationship.

True.

Agree with Etienne that hardball negotiation can only get you so far. A good relationship with your supplier is harder, but gives more opportunities.

Hardball negotiation is about who gets how much of the total profit. It’s win-lose.

If you have a good relationship, the question is more: ‘how do we reduce the total cost so that there is more profit to share between us?’ This is win-win. So now the factory has a good reason to work with you to redesign products, standardise components and so on.

Also for logistics, if you are servicing different geographic regions, it may be worth storing most of your product close to the point of manufacture until you know what the demand is in different regions. That’s one reason Hornet has warehouses in China – clients can store product there and keep their options open!

Yes I fully agree. The Chinese are not used to win-win deals, but over time a customer can show they are serious and get a supplier in the right thinking mode.

Thank you for the excellent post, Renaud! Insightful and useful as always.

Great comments too!