A few weeks ago, a friend who has worked in a midsize inspection firm for a while told me “there is a rule in the industry: you won’t keep all your clients forever — you will lose them one by one”.

A few weeks ago, a friend who has worked in a midsize inspection firm for a while told me “there is a rule in the industry: you won’t keep all your clients forever — you will lose them one by one”.

Fortunately, my first client still works with me after 5 1/2 years. However, I have observed this trend with most of the clients who decided to use our inspection services — particularly those purchasing upwards of 5 million USD a year in a single product family.

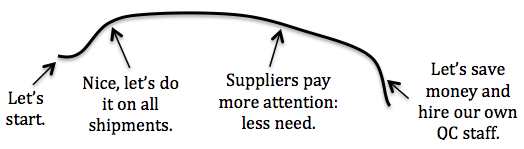

Volume of inspections: the natural cycle

At the beginning, there is a lot of work for two reasons:

- Some suppliers are not reliable, so we check their products during production as well as before shipment;

- Some problems are found, so there are re-inspections.

After one or two years, though, the worst manufacturers have been replaced by new ones, and all suppliers understand what is expected of them. There is less need for QC inspections. The smallest shipments aren’t even checked any more.

Finally, the importer is looking for ways to save money. The number of quality problems has gone way down, so is there still a need for a high QC budget? The buyers of cheap products usually hire their own staff.

The buyers of high-quality products, who want to work with reliable and proven processes, either send someone from their head office to manage product quality full-time… or keep working with a third-party QC agency.

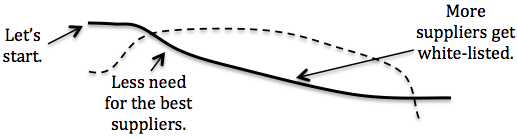

A better solution for buyers with a high quality standard

As I wrote in this past article, it is fundamental to distinguish several categories of suppliers, and to treat them differently.

First, it is necessary to collect information about each supplier. If there is no history of inspection results, a classic “one inspection per shipment” policy is necessary.

Very quickly, it is possible to see which suppliers are safe, and to check their products less frequently. This is quick way of saving money.

Over time, the average quality of the suppliers goes up. The worst (“red listed”) suppliers are followed closely:

- Setting up a product specification checklist, translating it, and explaining it to the factory;

- Accompanying the factory technicians during pre-production sampling, and during production launch;

- Checking every sensitive production step (or even stationing an inspector on site for several weeks).

This “smart quality assurance” policy can be 30% cheaper than a classic inspection policy after 6 months, and at the same time reduce quality risks.

Anybody has similar experiences?

This

is a very timely article for me as we are changing our QC inspections process.

Our manufacturers are staying the same (and some are very reliable while others are not!). However, how we warehouse our products

is changing thus our inspection procedure has to change. Currently we

perform final inspections on every batch of product made. Soon we will be training and putting more

of the responsibility on the manufacturer’s quality teams to perform inspections during and after production. While we will only perform

spot inspections. Do you have any advice for a transition similar to this? And any areas for concern to be aware of?

Thanks

as always for the excellent post!

JW

What you are trying to do makes sense.

If you can, train 1 or 2 “factory certified inspectors”, and watch then do their job on your orders for a couple of days. Don’t give them a complex procedure!

And it’s give and take: if you inspect less often, you can (hopefully) require regular updates.

More advice on http://www.qualityinspection.org/training-internal-inspector.

Soon we will know if it makes sense when we put it to practice! That was our plan to train a few workers, review their reports and build a good working rapport to ensure the quality remains up to our standards. Our QC inspection form is not complex, pretty easy to work off of. Glad to hear we are on the right path! Thanks also for the additional link……

All the best.

– JW

I’ll be curious to hear about your experience. Don’t hesitate to reach out and ask for advice along the way.