After building a prototype and subjecting it to functional tests, you will likely need to make revisions from both a functional standpoint in order to ensure the product actually meets the business goals as well as from a product specification standpoint, which could include cosmetic changes like shape, size, color, and finish.

After building a prototype and subjecting it to functional tests, you will likely need to make revisions from both a functional standpoint in order to ensure the product actually meets the business goals as well as from a product specification standpoint, which could include cosmetic changes like shape, size, color, and finish.

We’re now at phase 5.5. Don’t forget that you can see the whole series on developing a new product here.

An iterative cycle would include a design review where all the test data are presented and analyzed so that changes can be suggested and planned, another prototype built (which could just be a sub-section or the whole product, depending on the change required), further testing of the product to gather data, and then that data needs to be defined, ready for the next design review meeting.

These design reviews are not only a method to help verify the design of the product, but also a means to reduce the risk associated with the new product.

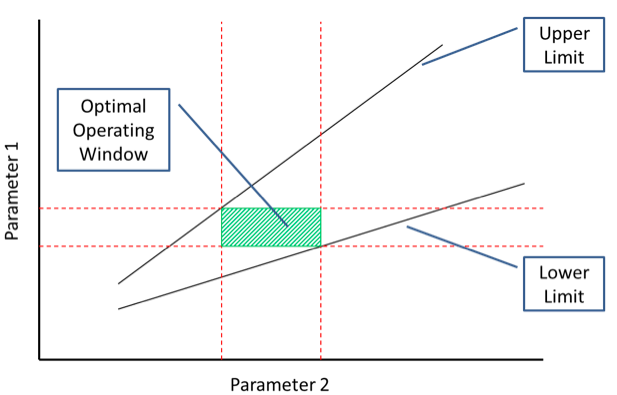

Operating Window

The test data presented during the design reviews should include limit testing, to understand what the operating limits are; this should include failure thresholds as well as optimal operating conditions. These data should provide information on the tolerances within the system and sub-systems of the product, a simple example of this is shown the figure below. In the ideal situation, the system operating window should be a large as possible thus provide a more robust and stable product. A small operating window means the system is sensitive to change which could ultimately create problems when the product is in the marketplace, which would result in great warranty claims and returned products.

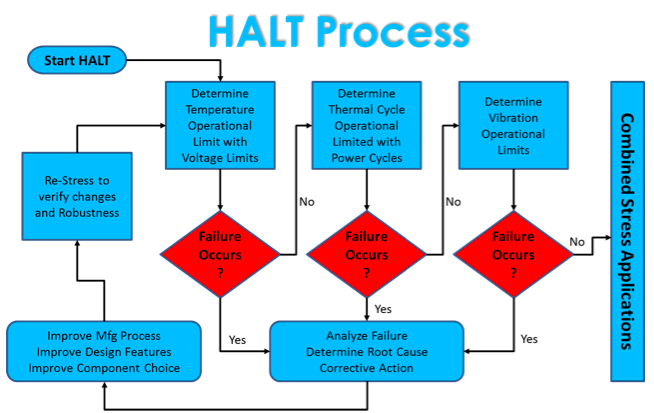

Other test data presented should include result from Highly Accelerated Life Testing commonly referred to as HALT.

Interested in this topic? You may also like Sofeast’s New Product Launch Roadmap [XLS + Video]

Our ‘new product launch roadmap’ unveils the steps that your supplier will never tell you are needed, and yet all veteran buyers consider as indispensable. Hit the button to get your copy:

Highly Accelerated Life Testing (HALT)

HALT is intended to identify weaknesses within the design during the development stage of the product so that they can be fixed or designed out before the product gets to production. Highly Accelerated Life Testing includes vibration, high & low temperatures, rapid temperature cycling, and humidity, combined stress, on/off cycling, voltage limits and frequency limits. The HALT process is shown in the figure below.

The Review Cycle

Design reviews are conducted with a design review team composed of experienced, senior-level personnel who understand the technology involved in the product or system and its associated technical risks. Ideally, these personnel should not be directly involved in the program in order to provide an objective perspective on the design.

Design review team members are chosen to match their skills and expertise to the requirements of the project. The team is multi-functional to address all the subject matter and issues covered during the review. The team may stay in place for the project or new personnel may be added and existing design review team members dropped as the project evolves in its development cycle (source: NPD – solutions DRM Associates).

This cycle continues until no changes are required and the product gets signed off as pre-production ready. At which stage a technical data file needs to be generated in order to send to suppliers. The Design Review Iteration Cycle is shown in the figure below.

Go to part 11: Build Of Pre-Production Tooling

Want to learn more about the new product introduction process for hardware startups?

Whether you’re some way along the process, or just starting out, Sofeast’s guide covers everything hardware startups need to know for making a new product in China and successfully bringing it to market.

Hit the button below to read the guide: