A large part of the new product development process is the series of approvals to get through. It helps prevent quality issues in mass production and it helps reduce miscommunication… both of which are the biggest causes of a slower time to market.

If your company develops and manufactures new products regularly, do you have a documented process? These 3 examples from the apparel, auto, and electronics industries can help you understand how the approvals work.

Let’s start by looking at the way new garment styles are developed.

1. What makes sense for most mechanical & electronic products?

There are several ways to document this new product development process.

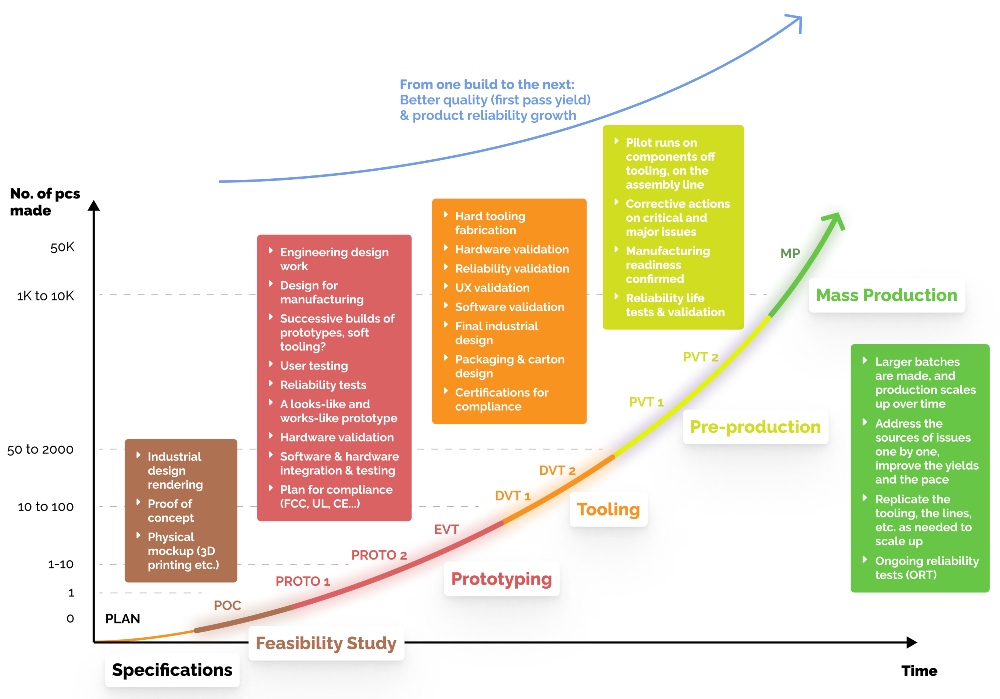

Consumer electronics companies in the US tend to have their own jargon (EVT, DVT, and PVT phases). They aim at productions of millions of pieces. Here is the way we drew it:

I like this approach, and it has proven quite useful, including for relatively simple products and for relatively low-volume productions, too.

Other companies, mostly in Europe, talk about TRLs. But it focuses too much on the product design aspect, and insufficiently on the process (to manufacture and to test the product). I usually do not suggest that approach.

Here are some of the key points about new product development in this category (electrical and/or mechanical products):

- A new product design, when it comes out of the inventor’s mind, is often quite immature. In 95% of cases, very little consideration has been given to the way the components will be manufactured, or to the final assembly & testing methods.

- In some cases, a new concept is just technically impossible to make with today’s technology.

- For certain products sold in certain markets, passing the required certifications (CE, UL, FCC, etc.) can be quite a challenge. It needs to be taken into account from the start.

Note: we wrote a guide on the New Product Introduction (NPI) process for electro-mechanical products.

2. The new automotive part development process

The auto industry has gone as far as they could to ensure the quality of the parts they buy for several reasons:

- A new vehicle is planned to sell in the hundreds of thousands of units. A successful model may sell over a million units.

- If one component is delayed, an entire car assembly factory might have to be down, leading to massive losses.

- If a supplier has to be switched midway through the life of a car model, a lot of very expensive testing (crash tests, etc.) might be necessary.

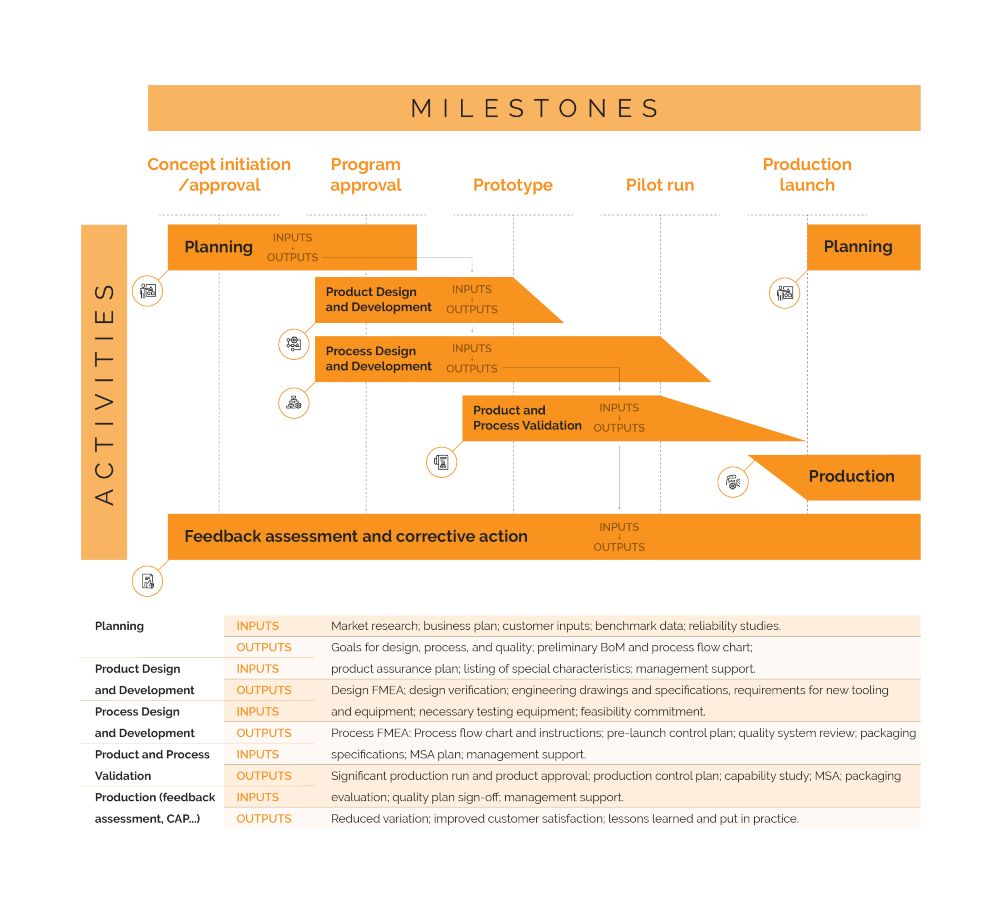

Automakers in North America and Europe (GM, VW, Ford, and so on) have addressed this risk by requiring their component suppliers to follow the APQP (Advanced Product Quality Planning) approach.

Just like we showed in section 1, there is a lot of focus on designing and validating the manufacturing and the measurement/testing processes. It is a great framework.

On the buyer’s side, this is also managed by a series of approvals that is called the PPAP (‘Production Parts Approval Process’). Wikipedia does a nice job listing the elements typically required by the buyers.

Note: this is above and beyond what most importers, even industrial buyers, require when they buy products or components from Asian suppliers. I listed some of the differences in this post a few years ago.

3. The new garment development process

Here is what it looks like for many importers (with a few variations, naturally):

- The customer’s designer gives a drawing or a sketch of the style, the colors (usually Pantone codes), and sometimes the accessories (bows, lace…) chosen. It often takes the form of a “tech pack“.

- Alternatively, it can be on the basis of an existing product sent to the supplier with a few comments (“find a similar fabric on your local market, color should be green…”).

- The supplier might be given the order quantity breakdown (per size, per color), an idea of the market (e.g. “UK size”), and the packaging information, for quotation approval.

- The supplier prepares a “look good” sample in exact fabric, available color. And submits fabric swatches of the exact fabric in exact color (make sure these are not too small).

- The customer may request changes (a different material, a different accessory, a different look, different stitching…).

- Once the look is approved, the supplier prepares 1 or 2 samples in exact fabric, available color, in the base size (medium). It is important that the supplier provides a size chart at that time (for just that 1 size), too.

- The customer tries the fitting and may request changes in the workmanship, in required value(s), or in tolerance(s).

- The supplier prepares a full set of size samples (1 or 2 samples in each size, in exact fabric, available color). It is important that the supplier provides a full size chart at that time, too.

- All along, the customer’s designers and/or fit technicians document their comments. This will be important for the manufacturer to keep in mind, and also for the quality inspectors.

- Once the fit is confirmed, and all details have been specified (including labelling and packing), the customer usually sends the first payment or opens the letter of credit.

- The supplier purchases the materials & accessories in the exact color.

- The supplier makes samples in exact fabric, exact color, exact sizes and sends them to the customer for final approval of all aspects of the products.

- If all is OK, the customer gives approval to proceed with production (laying the fabric, cutting it, sewing, final treatments if any, and packing).

- If there are risks with the main fabric, an inspector may be sent to the factory to conduct a fabric inspection (typically a visual inspection based on the ASTM D5430 standard, or “American 4 point system”).

- In many cases, the supplier sends some samples again from the “top of production” (meaning they are the first ones sewn by production operators in the workshop, not in a separate sample room), and ideally, these samples are fully packed, too (in which case they may be called “shipment samples”). If the top samples are not approved, corrective actions need to be implemented immediately, and new top samples may need to be sent.

- An inspection during production is common if this is the first time this style is made in this factory on this line(s). It may be an in-line inspection (checking the sewing process) and/or an inspection of completely sewn samples.

- A final random inspection is common. It has to take place before the payment of the balance owed to the supplier.

This is very, very widespread in the apparel industry.

If you buy garments, ignoring this ‘classic process’ is dangerous, for a simple reason: suppliers have been trained to follow it and removing some of these validations create extra risks.

For example, years ago, an importer started buying apparel from a Chinese supplier. They felt very confident in that supplier because they got strong references. They unlocked the payment before colors were approved (this virtually never happens with other importers). The supplier’s purchasing staff thought they had the green light to purchase the fabric, and as a result, production was not in the right color….

As you can see, the garment industry focuses a lot on physical product samples but pays very little attention to the manufacturing process, and that can be deadly in some other categories.

*****

I hope I gave you food for thought. Ultimately, you need to think of the steps (what to do, and who will do what) and approvals (who needs to confirm what, at what step) of a new product development process that makes sense for the type of products you want to manufacture.

The right approval (go/no go) gates will prevent very expensive missteps.

Any questions or comments for me on this topic? Let me know in the comments, please.

Are you designing, or developing a new product that will be manufactured in China?

Sofeast has created An Importer’s Guide to New Product Manufacturing in China for entrepreneurs, hardware startups, and SMEs which gives you advance warning about the 3 most common pitfalls that can catch you out, and the best practices that the ‘large companies’ follow that YOU can adopt for a successful project.

It includes:

- The 3 deadly mistakes that will hurt your ability to manufacture a new product in China effectively

- Assessing if you’re China-ready

- How to define an informed strategy and a realistic plan

- How to structure your supply chain on a solid foundation

- How to set the right expectations from the start

- How to get the design and engineering right

Just hit the button below to get your copy (please note, this will direct you to my company Sofeast.com):

Hi,

I will need inspection on about a few hundred to a thousand US bound electronic devices.

We will bringing in digital photo frames from Shenzhen and will need quality inspection of the products.

Please let me know what the process entails and the cost associated with it.

Thanks

Sure. I am going to send you an email.