By Fabien Gaussorgues

By Fabien Gaussorgues

Selling on Amazon has been attracting more than 100,000 new companies a year! The ‘Fulfillment By Amazon‘ (FBA) model is particularly interesting.

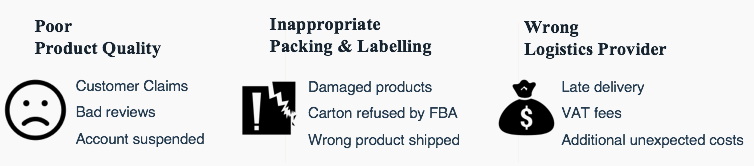

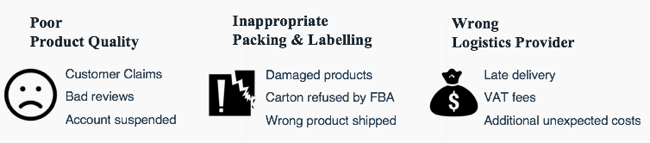

However, we see the same issues coming back again and again. Here are the 3 most common sources of supply chain failures for FBA sellers:

Let’s go through them one by one.

1. Poor product quality

- Products that were manufactured at an inferior standard — note that this is quite common, even when the buyer received a perfect pre-production sample.

- Products that got damaged during transportation.

2. Inappropriate labeling and packing

- Wrong labelling (e.g. FBA vendors are required to use a unique UPC code and Amazon labelling).

- Weak export cartons, or inappropriate individual product packing.

- Oversized export cartons — for example each carton should not exceed 50lb. and 25” on the side, not to mention product-specific requirements for jewellery and other categories.

3. Using the wrong logistics provider

- Delayed deliveries with little or opaque information from the freight-forwarder.

- High custom duty fees (impacting the margin dramatically).

- Some ‘sensitive’ products such as batteries or scissors are refused by most shippers.

The Impact of these issues regularly leads companies out of business. For example, poor product quality impacts a company in several ways:

- Customer complaints and product replacement costs.

- Bad reviews from customers, leading to lower sales.

- Account gets suspended if average defective rate is over 1%.

As a small company, how can you control and prevent those risks?

You need to control your supply chain from A to Z. Some FBA sellers to this:

- Ship the goods directly from the factory to their home;

- Inspect 100% of the goods by themselves;

- Repack and stick Amazon labels;

- Ship goods from home to Amazon warehouse(s).

However, this is not realistic if you have a small team and you want to spend most of your time finding new products to sell, marketing, and doing after-sale service.

As a result, more and more China-based sourcing agents have targeted FBA sellers. The objective is to simplify your logistics by combining quality control, logistics and fulfilment directly from your supplier to FBA warehouses.

Many FBA sellers try to find a Chinese sourcing agent for this — the reasoning is that few Chinese have the marketing skills to succeed on Amazon, so there is little chance they can become a competitor.

The problem with those sourcing agents is that many of them still take an undisclosed commission from the factory’s side. And their QC inspections are seldom professional. Be careful who you work with…

—

By the way, at Sofeast we have been helping a number of FBA sellers in China. See our solution for FBA sellers here.

0 Responses

You write an article about shipping cartons or cardboard boxes. What to ask from your supplier, how to check it, how to know how heavy duty of a box to ask for, ect.

Thanks for the great reading!

This article will probably be of interest to you: https://qualityinspection.org/protect-shipment-china/