China is the largest exporter of apparel. There are several reasons for this: the low cost of labor, the know how in producing low-to-medium-end products, the great business environment, but also the low cost of fabrics. And, not surprisingly, most other countries import fabric directly from China for their garment production.

China is the largest exporter of apparel. There are several reasons for this: the low cost of labor, the know how in producing low-to-medium-end products, the great business environment, but also the low cost of fabrics. And, not surprisingly, most other countries import fabric directly from China for their garment production.

If we want to generalize, South China produces knit fabrics, while the provinces around Shanghai produce woven fabrics. I am not sure why, but most of our fabric inspections take place in the Shanghai area (Shaoxing city seems to be a huge production base for fabrics).

The procedure to check fabric rolls is pretty straightforward. But at the same time I would not advise someone who is not familiar with fabrics to do it alone. So I am not going to write a “how-to” guide.

This is a general presentation of fabric inspections. They are quite different from consumer product inspections. What I described in Quality Control Basic Concepts applies to garments, but not to fabric rolls.

How to draw the samples to check?

If there are 10 rolls and each one is a different type of fabric or a different design, all the rolls have to be checked. However, in most cases there are several identical rolls, and statistical sampling helps us reduce the amount of work.

When there are many rolls, we follow the AQL tables–the statistics used to prepare a sampling plan for inspections of consumer products. They provide the best efficiency/reliability value. But some clients impose their own methods: for example “take 10% of the rolls at random”, or “check the square root of the total number of rolls”. All are usually workable.

What can be checked?

The number of presented rolls, and the length & width of each inspected roll, are verified. Some tolerance is necessary because the factory’s machine (see above image) is often imprecise.

Usually the client sends some fabric swatches for reference. It is great to check the conformity of production. The weight and the yarn count are also checked.

Some quick tests can also be performed by the inspector–for example, checking the shrinkage and the color fastness after washing. But samples should be sent to a testing laboratory if precise results are required.

Lastly, packing and labeling only take a few minutes to check.

How to determine if there are too many defects?

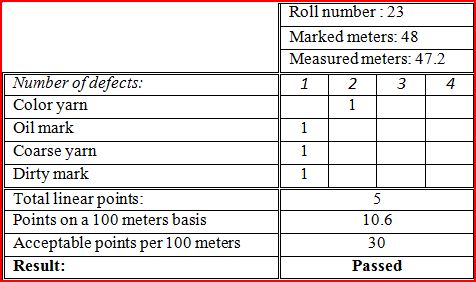

The most commonly used system is the American 4 point system. The ASTM D5430 standard explains how to assign points to each defect–mostly based on its size.

The most commonly used system is the American 4 point system. The ASTM D5430 standard explains how to assign points to each defect–mostly based on its size.

The buyer has to specify an acceptance limit–for example, no more than 30 points per 100 meters. So if the inspector finds 5 points on a roll that is 47 meters long, it is accepted (see image on the left).

The overall result consists of two numbers (and they are all most buyers want to know regarding defects):

- The average number of points (on a 100 meters basis) of all inspected rolls,

- The proportion of rolls above acceptance limit.

A great list of fabric defects can be purchased here, but I would say the most important is to use an inspector who was properly trained to inspect textile fabrics.

Dear sir

i want to know American 4 point system of fabric inspection ?????

Thanks

mizanur rahman

See this page: http://www.astm.org/Standards/D5430.htm (it is not free).

can u please send us basic details how to check the fabric inspaction as per 4 point system

Basically: you check a whole roll, you give a number of points to each defect (according to its size), and at the end you count how many points you have by adding the points of all that roll’s defects.

All is detailed in the standard, but I have no right to put it online.