There has been a lot of talk about the “factory of the future”, and the role of “quality 4.0” will play in that picture. Hundreds (maybe thousands) of IT applications, sometimes supported by IoT devices, have been developed. But what are the few key applications for manufacturing and quality management that will really drive business value?

Quality Management survey

The Boston Consulting Group, together with the ASQ and DCQ, have conducted a survey and published “Quality 4.0 Takes More Than Technology“.

Their analysis aimed at answering my question about applications that will drive business value.

They “focused on the opportunities and challenges arising from Quality 4.0—the application of Industry 4.0’s advanced digital technologies to enhance traditional best practices in quality management.”

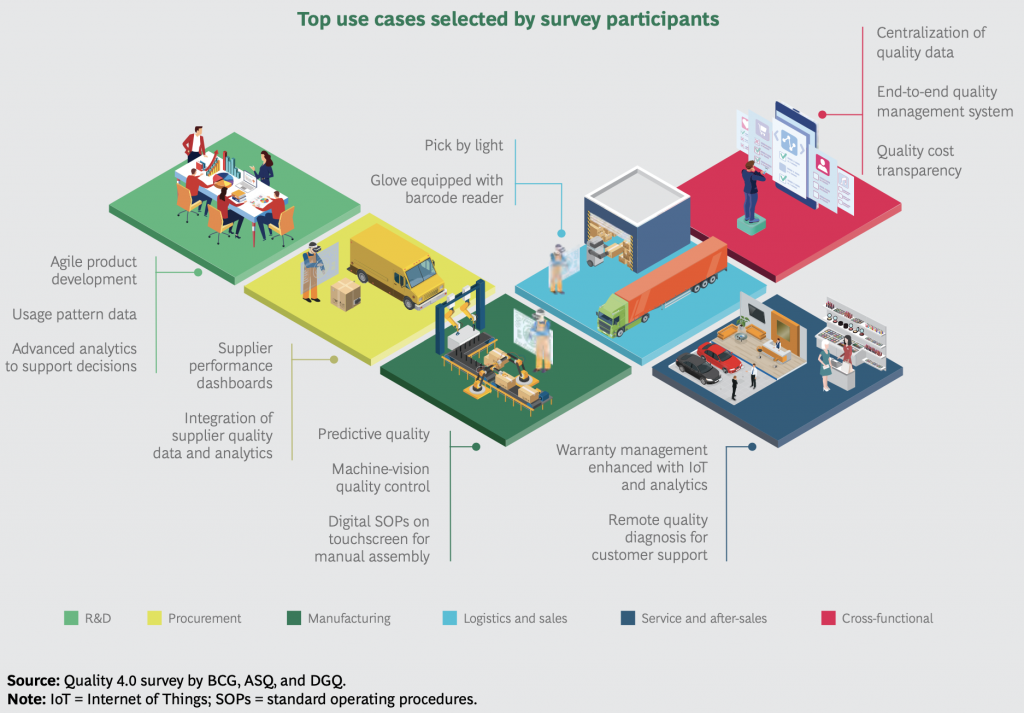

Respondents to the survey selected the most promising applications, which are shown below:

Key software applications arising from the survey

I thought I’d review some of the key applications mentioned in that report.

Applications for R&D

Professional software used by R&D engineers already allows plenty of simulations, but the key here seems to be finding potential failure modes, not only at the part level but also on the whole product, at the design stage. Artificial intelligence (based on past issues on relatively similar products) will probably help.

As I wrote before, many defects are actually design-related, not manufacturing-related. Improvements at this stage would be very beneficial.

Applications for supplier management

Tracking supplier performance is increasingly easy and is already done in one form or another in many companies.

Software like our own SynControl allows buyers to digitize product inspections and factory audits, allowing for rich analytics.

Applications for manufacturing

When the content of the job to do changes regularly, paper-based work instructions are not a good fit for operators, and using screens that get refreshed at each changeover supports better productivity and quality.

Analyzing rich data sets and noticing relationships between variables can be quite powerful, too.

Machine vision has become better and better, and much more affordable than 30 years ago. They can catch issues very early and replace some of the manual inspections currently being performed.

Applications for quality management and cross-functional collaboration

Quality-related data are collected all along the design-buy-make-sell cycle and should be centralized. It allows for a better understanding of what happens, what issues to avoid, and how much quality (failures + prevention + appraisal) costs the organization.

I thought this was interesting. In your company, or your suppliers’ factories, what have you seen? What IT applications for manufacturing and quality management have already made a nice difference to your operations? Let me know by leaving a comment, please.

8 Elements of a Low-Risk Supply Chain in China

This FREE webinar will empower you to transform your supply chain in China to reduce risks. Two industry experts, Renaud Anjoran and Paul Adams from Sofeast, talk you through how to gain control over your product’s quality, on-time shipments, long-term pricing stability, and continuity of supply.

Ready to watch? Register by hitting the button below: