The number of Chinese factories that are shut down by the government because of their environmental impact keeps growing. More and more supply chains get disrupted. Some companies that relied mostly/solely on one source are dying.

So the question is, is this going to happen to your suppliers?

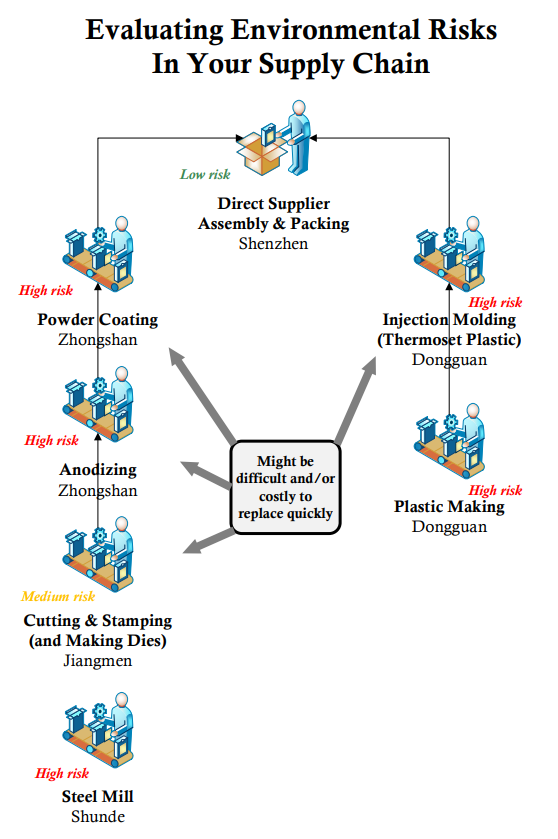

The response often lies outside of your direct suppliers’ walls, as they depend on their own suppliers. If one of the components or subassemblies is suddenly unavailable, production might have to stop for months.

Why is that? Tooling might have to be transferred (or made again), the sub-suppliers that are still open might have a long backlog of orders, and your supplier might simply be waiting for the factory that was closed to open up again!

How to get a rough idea about the risks you are running?

We wrote an article about it on the CMC blog: Predicting Painful Factory Closures In China: A Case Study.

We thought of a simple product with 2 components:

That’s quite a few potential points of failure!

That’s quite a few potential points of failure!

One big “but” is the supplier’s willingness to share that level of information. Most Chinese suppliers are insecure and feel their customers will be tempted to get rid of them if they understand their supply chain better. That’s hard to fight and you might have to start developing a backup manufacturer and maybe even find & qualify some of the sub-suppliers yourself…

Are you wondering how to find a manufacturer in China who is well-suited to your needs and can also deliver on their promises?

Sofeast has developed 10 verification steps to help you find the right manufacturer. They’re shared in this FREE eBook: “How To Find A Manufacturer In China: 10 Verification Steps.”

It covers:

- Background checks

- Manufacturing capabilities

- Quality system auditing

- Engineering resources

- Pricing, negotiation, & contracts

- …and much, much more

Just hit the button below to get your copy: