We sometimes get this question from clients who don’t have a long experience of working with Chinese suppliers:

We have been customers for a long time but they still refuse to give us credit. Is that typical/normal?

And the short answer is, yes, it’s typical unless you are a large and well-known company.

Unfortunately, it isn’t common for Chinese suppliers to give credit. Many long-time customers still pay 100% of their orders before they are shipped.

And that’s part of the “hidden costs” of outsourcing manufacturing to China. You have a lot of paid inventory that is waiting for shipment or that is on the water. You need more working capital to finance it.

The longer answer is a bit more complicated. I covered it, in part, in an earlier article (How to Pay Chinese Suppliers by T/T).

Paying 100% of the order before shipment is not great

As I wrote before:

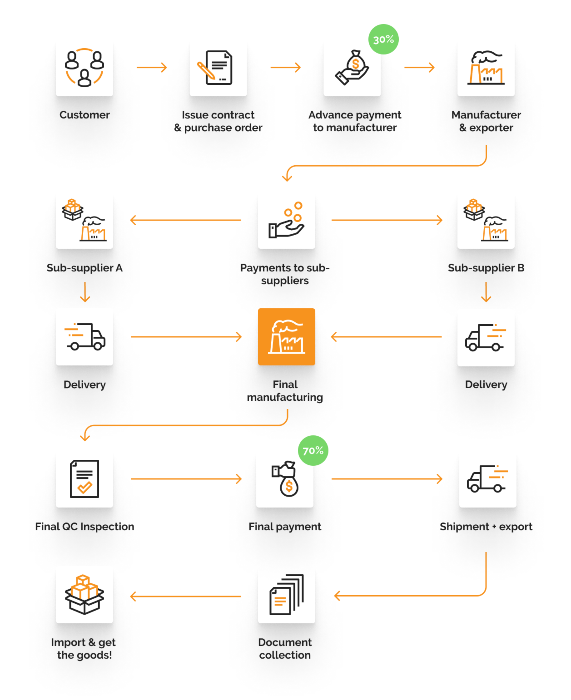

The most common payment method is a bank wire that works this way:

- You have the supplier develop sample(s) until you are confident they know exactly what you want.

- You send a 30% deposit (by T/T) before production starts.

- Your supplier (the manufacturer & exporter) purchases the components and/or materials and arranges the production

- You work with a quality assurance firm to inspect product quality (this is optional but usually a good idea).

- You send the remaining 70% (by T/T) before shipment.

- The supplier ships the goods and sends you the documents by express courier.

This is typical if the factory sees you as a small or risky customer. The manufacturer might decide not to ship the goods to you after you have paid them in full (that very seldom happens, but in case of a dispute it is an option at their disposal).

So, if this is your situation, you should try and negotiate something better…

Another set of payment terms that are better (for the customer) and that are not unusual

You can probably push your supplier to accept payment of the remainder after shipment if it’s shipped FOB by sea (and you pay before they send you the original bill of lading).

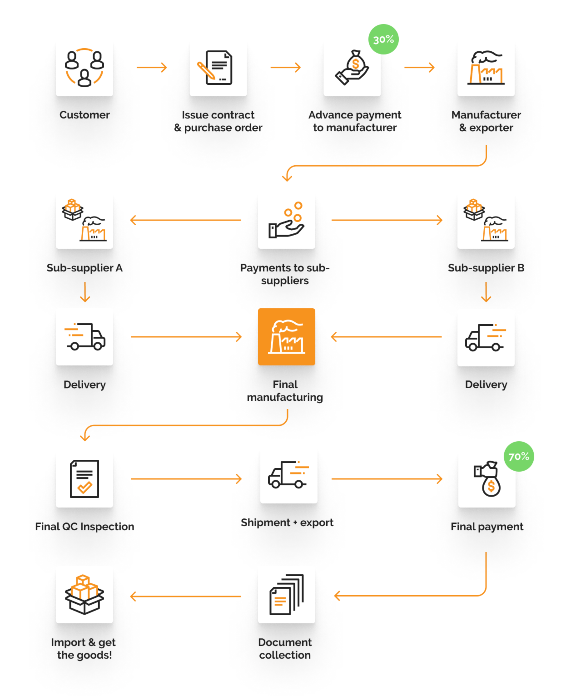

As I wrote before, this arrangement is similar to the one above, except when it comes to the end of the process:

-

Once the supplier confirms the goods are ready, send an inspector to check qualityIf quality is OK, release the goods (allow the goods to be shipped out) — this works best if you purchased under FOB terms

-

Once the goods are on the ship, the supplier gets the Bill of Lading (B/L), and sends you a copy of it

-

If the product name, quantity, etc. are all fine on the bill of lading, you send the final payment to the supplier

-

Once the supplier receives the payment, they send you the original B/L

It looks like this:

Why is it better?

- The buyer knows the goods have been shipped out before paying the remainder.

- The supplier knows the buyer can only take possession of the goods after the original bill of lading has been sent.

Can you negotiate this term? If you insist on it from the very start, and if your suppliers are motivated to work with you, probably yes. If you come out as a beginner and your orders are very small, probably not.

Another set of payment terms that are seldom accepted

Here are other terms that I have seldom seen, but that aren’t unrealistic:

- Pay 30% before production, pay 50% before shipment, and pay 20% within 10 days after receipt of the goods — this reduces the temptation for the supplier to play little games, such as “salting” bad pieces into the cartons after the final quality inspection.

- Instead of paying 30% before production, negotiate this down to 10% or 20%. If you purchase products that are not heavily customized and that they can easily resell in case you cancel your order, you stand a relatively good chance of negotiating that.

- If you place orders over 50,000 USD and you strongly dislike sending payments before production starts, you might be able to negotiate payments by letter of credit.

A last word of advice

If you suddenly request better payment terms, the supplier is likely to say no. If you tell them that your plan is to get certain terms from the very start (before you have spent time preparing for an order with that supplier), it is easier to get concessions.

And you might have to negotiate for better payment terms after the first order, or after the first 2 orders, since the supplier also needs to cover their risks of not getting paid for their own work…

Are you trying to find a manufacturer in China who is well-suited to your needs and can also deliver on their promises?

My company Sofeast has developed 10 verification steps to help importers find the right manufacturing partner in China. They’re shared in this FREE eBook: “How To Find A Manufacturer In China: 10 Verification Steps.”

It covers:

- Background checks

- Manufacturing capabilities

- Quality system auditing

- Engineering resources

- Pricing, negotiation, & contracts

- …and much, much more

Just hit the button below to get your copy and put yourself in a great position to get better results from Chinese manufacturers who supply your products:

How popular in your experience are credits from Sinosure?

On the Chinese supplier side, I am not sure. It seems they resort to Sinosure when a customer hasn’t paid them, mostly.

On the non-Chinese importer side, I have never heard of anybody choosing to work with Sinosure.