A pre-production inspection takes place either before production starts (usually to check inputs) or at the very beginning of final assembly.

A pre-production inspection takes place either before production starts (usually to check inputs) or at the very beginning of final assembly.

It is the least frequently used among the four major types of quality inspections for most consumer products. On the other hand, for industrial goods and for highly-customized products in general, production has to be followed very closely at this stage.

When to conduct a pre-production inspection?

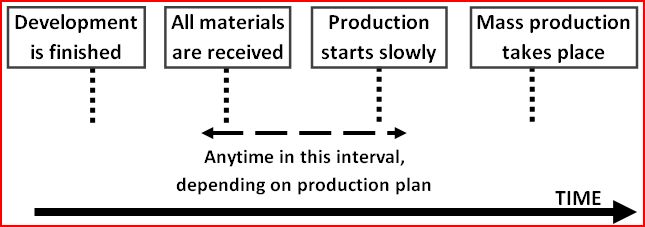

It really depends on what the buyer wants the inspector to see/check. I worked on a little sketch to represent the key dates to watch closely:

Sending an inspector so early is also a way of ensuring that production starts without delay. If the factory wants to give priority to another order, the simple fact that you monitor their progress will make them think twice about it.

What is checked during a pre-production inspection?

The buyer should specify clearly what the inspector must pay attention to.

Here are 4 things a P-P inspection can cover:

- The materials/components: factories often use the cheapest materials they find, and they are not always aware of restrictions in the importing country. If you don’t want to run any risk, the inspector can draw a few samples at random and send them to a testing laboratory. He can also verify their colors, sizes, weights, etc.

- A prototype: sending a sample of large furniture is quite expensive. Why not send an inspector to check it and send you photos, so that you can validate it as a reference for production without wasting time?

- The making of a first product(s): sometimes the buyer cannot see a “perfect sample” until the right materials are ordered and the bulk production processes are started. Here is the time to check whether the factory is capable of making products that respect specifications.

- The processes of mass production: the buyer may have certain requirements about the way to produce, and needs to check if they are implemented correctly.

What are the limits of a pre-production inspection?

The first pieces coming out of the production line are not necessarily a good reflection of average quality, especially when there are lots of manual operations. An inspection during production might be more useful.

Sometimes the whole cycle takes several weeks, so the inspector cannot see any finished product at all. It might be impossible to verify, or even get an idea about, the conformity to specifications just by looking at in-process inventory.

In some cases, a deceitful factory starts a short production run to make its customer happy, and then subcontracts the rest in another workshop. I remember an importer who sent 2 technicians to China for the sole purpose of setting the machines properly and checking the first days of work. I went to inspect the goods 3 weeks later, and there was no doubt that what I saw had not been made on the machines set by the customer’s technicians.

Especially when working with a new China supplier, pre-production inspection is quite important. Even when working with tried and true suppliers, we still do quite a lot of p-p inspection (materials, color swatches, etc) at our textile company. Pre-production and Mid-production inspections can save you a lot of headaches–and also save a lot of costs (cost of material, labor, etc); oftentimes, too, a supplier will be more careful if he knows that you will be conducting inspections. In our 6+ years as an import/export company (working mainly with textiles and jewelry), we have found QC to be one of the biggest issues with every China supplier…which is why we do 100% inspection of any item leaving our warehouse. ANYTHING that you can do to increase quality will save you (and your end customers) many problems (unwanted rejects, re-negotiation with your angry supplier, wasted labor or materials).

Jill: thanks for the comment. I very much agree.

The earlier you catch issues, the easier and cheaper it is to find a solution… This is one of the few fundamental rules that so many importers don’t get.