I wrote extensively about ways to proactively improve a product’s design, in order to avoid quality, reliability, and safety issues. It involves reliability engineering, fail safe designs, and a variety of other objectives to take into account (see DFX). I realized I never covered what logically comes first… looking for ways to have a product “do its job” better. Such a design optimization process is well worth doing for products to be made in large quantities, as it can yield enormous benefits. It directly improves product reliability and user satisfaction, and sometimes it also allows for a cost reduction in the product’s bill of materials.

A good book about Taguchi’s approach to design optimization

Over the weekend, I read Robust Optimization Practices and took some good notes. This book is based on the approach developed by Dr. Taguchi about 40 years ago. It does a nice job of summarizing the concepts and showcasing their applications.

Let’s define robustness as the ability of a product or process to function consistently as the surrounding uncontrollable or uncontrolled factors vary.

An example is the power window system in the driver’s side door of your car. Does it perform today as well as it did the day you took delivery of it? On an extremely cold morning? On a hot summer day? When you are sitting in the car with the motor off? At 50 mph? Has the window ever stopped working entirely?

If two window systems are being compared, the more robust window system is the one that performs most consistently over a large number of cycles, at low and high temperatures, when running on battery power, or when the car is moving a high speed.

In other words, higher robustness allows a product to be more reliable — to work as expected for longer in the field (in the hands of end users).

Let’s look at an example of design optimization

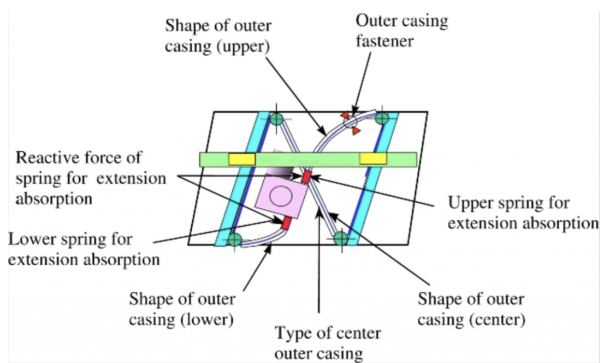

The book continues with the same example — the automatic windows lifting system. It showcases a design of experiments that provides a way to reduce the resistance to sliding.

Here are the different ways that module can be designed:

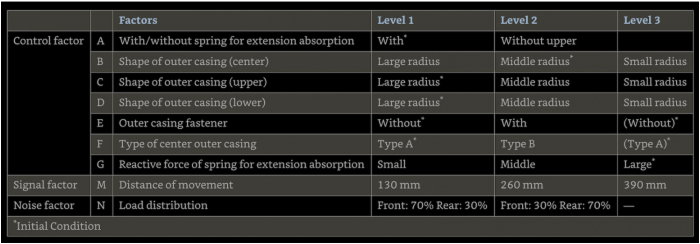

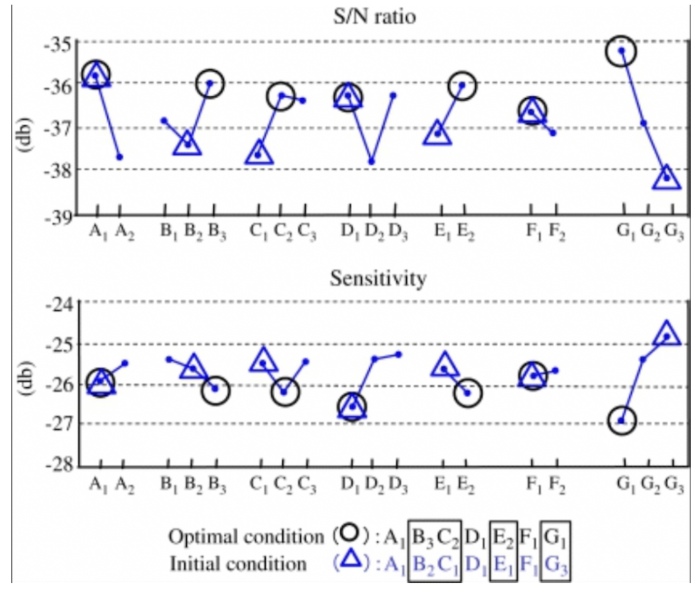

Based on those design parameters, the engineers picked 7 control factors and picked 2 or 3 values for each:

After a few experiments, it led the company designers to identify a more optimal set of parameters:

The new configuration leads to lower resistance. In this case, the torque needed went down by 15% and made less noise.

That’s what I call “doing the job better”, or as Taguchi would have written “better transmission of energy”.

The designers put the cable through a life test and measured the cable elongation, which was much lower with the new design — it allowed them to conclude that the reliability of this module had been improved.

In addition, a less powerful and cheaper motor could be picked, which means the product becomes cheaper.

Learnings for the design team… and their future projects

Here is the money quote:

Usually no more than six measurements are needed to estimate robustness. Most companies that use these ideas strategically develop special fixtures to help engineers estimate robustness quickly and efficiently.

What does it mean?

If you design the same type of product repeatedly, what you learn in one experiment (one of your designs) can be very useful to optimize relatively similar designs in the future.

The book gives a few examples. Xerox identified a few design parameters (paper feeding, toner dispensing, toner charging, toner transfer, fusing, etc.) and started to measure them on all their new copy machines, as a shortcut to improve their new products.

It is a complement to the typical design-prototype-test-fix approach

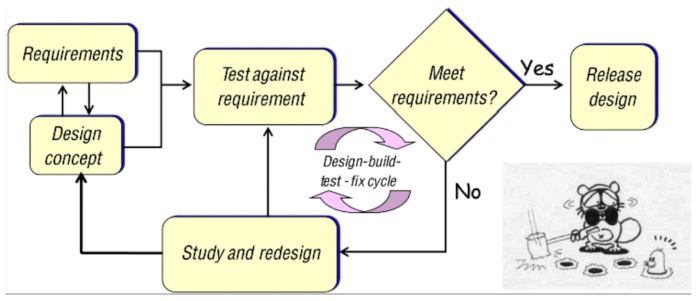

In the book, the authors mention the design optimization process as a proactive approach, in addition to the more reactive method of developing prototypes and testing them.

Here is how they represent the usual design-prototype-test-fix approach (and their analogy to a game of Whack-A-Mole):

I see them as complementary… even after a very well-conducted round of optimization, it is good to verify the impact on the product, as the changes may lead to unintended effects.

This is one of the biggest missing links in China manufacturing!

I believe the lack of a structured approach to designing & developing good products is the greatest missed opportunity for Chinese ODM and OEM suppliers.

With only a few exceptions, they develop products quickly, launch into production, and tend to ignore the feedback from the market. They sometimes spend a lot of time deflecting their customers’ blame and chargebacks for failed products… but they seldom wonder how to actually develop and make products that will fail less often.

I covered a typical example before in How Bad Product Design Leads to Many Quality Issues.

Have you got other similar examples?