How to ensure a product is going to be safe? By conducting a product risk assessment and acting on it.

The problem is, if I ask people how they assess risk, I may get widely different answers. A structured approach is needed. And the good news, it is out there and it is easy to understand.

Let’s focus on general consumer goods here. Some regulated spaces (e.g. medical, automotive…) have their own well-defined methods, but the underlying logic always tends to be the same.

1. How to do a product risk assessment in a step-by-step manner?

A nice approach is laid out in the ISO 10377:2013 standard, which provides guidelines for suppliers regarding consumer product safety.

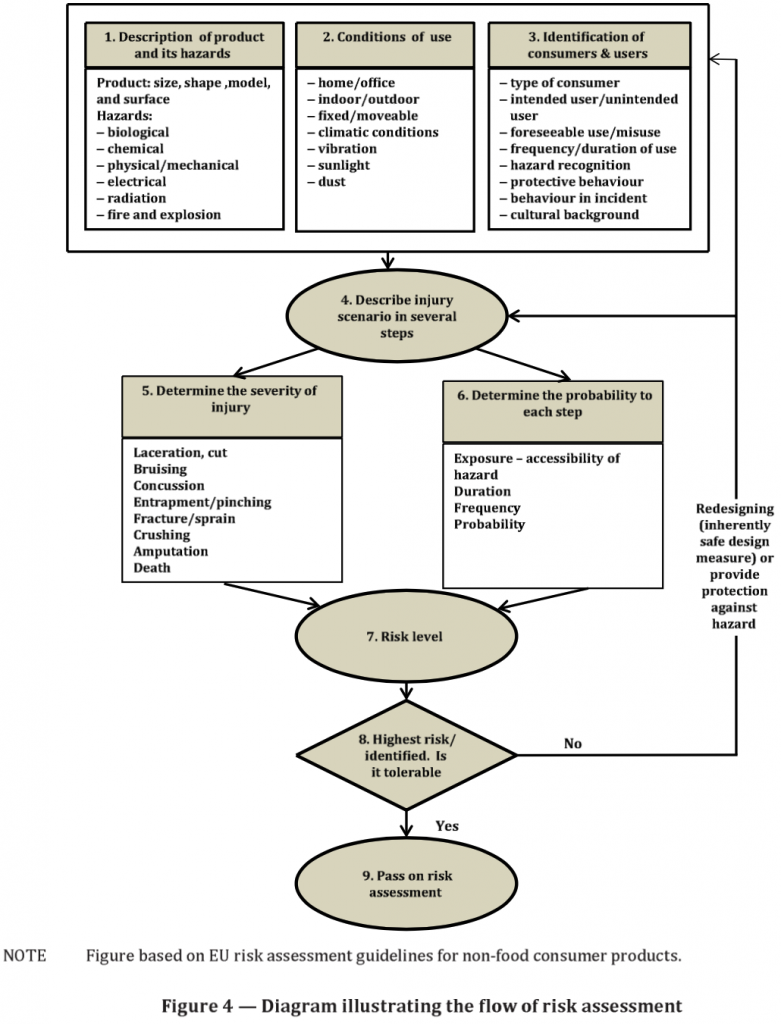

They summarized it in this flow chart:

Anybody who has done an FMEA will recognize the main difficulty here. Steps 1 through 4 should lead to a list of potential hazards, but getting there is often challenging for most teams…

2. How to avoid overlooking most sources of risk?

What do people need? Some available lists to pick from!

Depending on the product category, there may already be a list of likely hazards.

Let’s take an example: IEC 62368-1:2018 is a great standard (but a new version is coming out in a few months, so wait before you purchase it…). It deals with IT products.

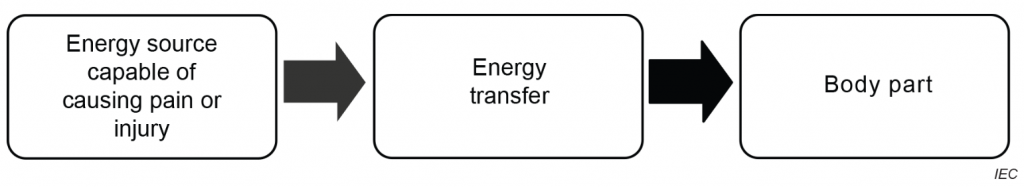

This is the basic framework they follow, and it makes a lot of sense for those products:

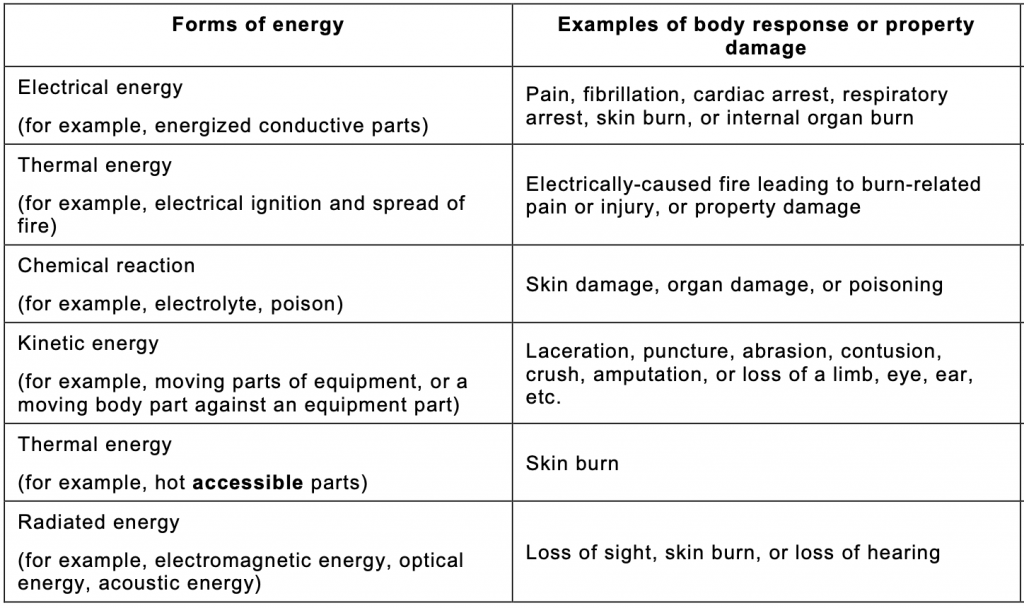

Conceptually, the technical committee suggested a list of 6 large categories of energy, and it’s a good way to start:

Any other list of hazards? Sure. I am sure one could find a lot on the internet or in industry-specific standards.

3. How to assign probability and severity, to assess the risk level of each scenario?

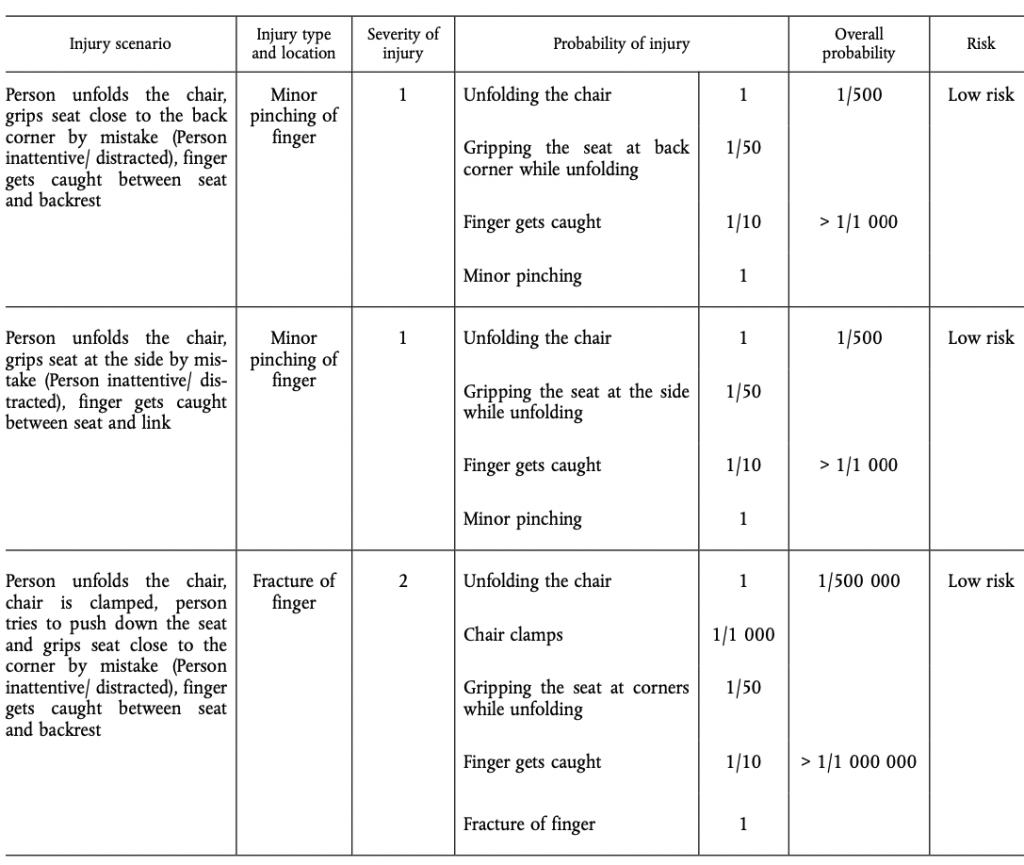

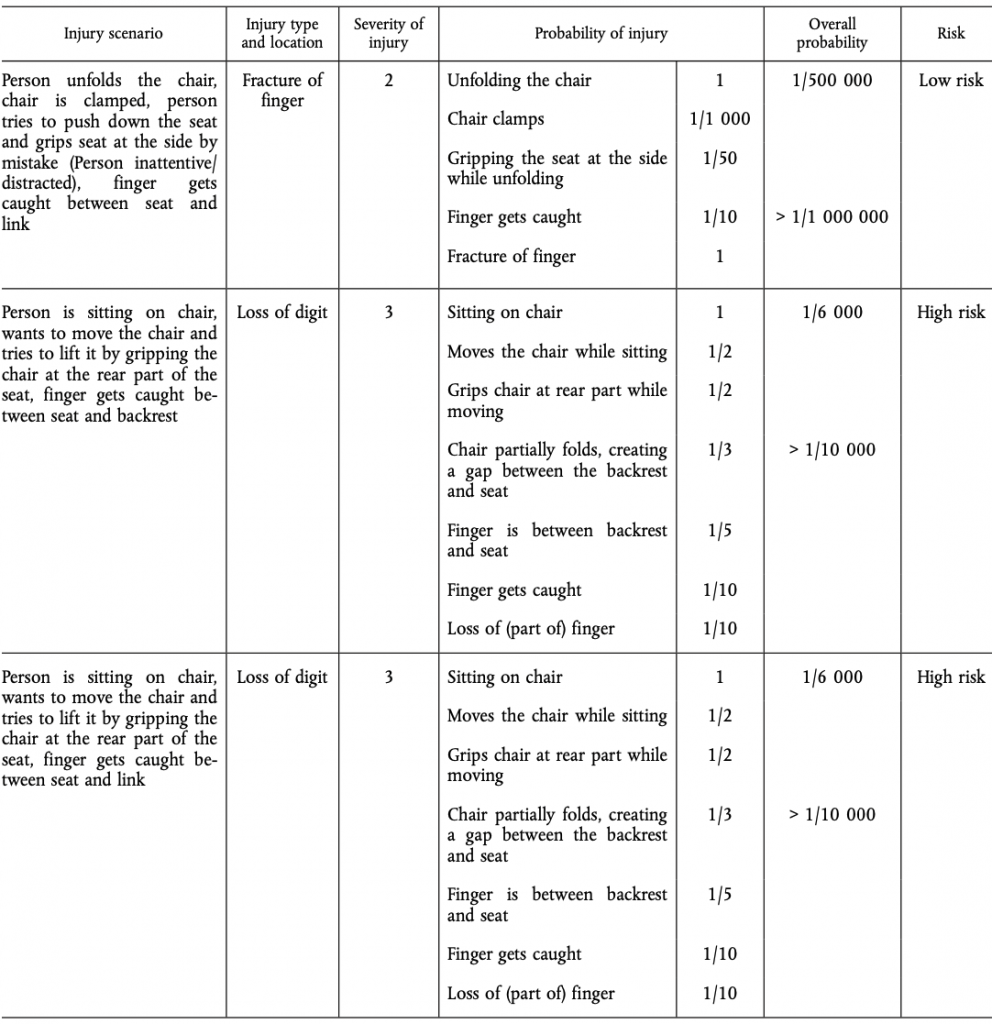

The guidelines for the management of the European Union Rapid Information System (RAPEX) — an insightful document that influenced the above-mentioned ISO 10377 standard — gives a nice series of example that illustrates this.

They show some injury scenarios that end up being rated as ‘low-risk’ or ‘high-risk’.

Many companies have their own guidelines for the way to assign severity and probability scores. This is just an example, but it is a great starting point.

4. What if some sources of risk are not tolerable?

The product designer’s focus, in that case, is to implement ‘safeguards’ (in IEC speak) to prevent those types of energy to transfer to people or property. (Isolation of conducive parts reduces the risk of electrical shocks, for instance.)

There are several types of safeguards. Requesting users to follow certain steps and to wear certain protective equipment is an administrative countermeasure, as Art Smalley would say. The IEC calls it a ‘behavioral safeguard’ and provides a list of other approaches.

******

Do you see a way to integrate the product risk assessment into your product design & development work? And do you use professional compliance software such as SynControl?

P.S.

This post covers how to prevent products from being unsafe or non-compliant in the first place which should be high on importers’ to-do lists, however, unfortunately, sometimes a non-compliant and/or unsafe product makes it onto the market and into consumers’ hands. In this case, you need to react to the problem, which might require you to implement a product recall program. We show you the guidelines for doing so here: Product Recall Program: How to do it in case of a Safety Issue?

P.P.S. Notes and related reading to the product risk assessment:

- It is useful for mitigating safety risks, but also to improve quality and reliability. See Why Product Safety, Quality, and Reliability Are Tightly Linked.

- It is much better to be proactive, reduce risks, add fail-safes where needed, remove design defects, and so on, rather than get complaints about failures.