The biggest frustration I have with Chinese engineers is their lack of interest in fixing the root cause of a problem.

The biggest frustration I have with Chinese engineers is their lack of interest in fixing the root cause of a problem.

Let’s say a machine’s printing mechanism deviates to the right, and their customer’s logo is totally disfigured. If they know their customer, they understand it is a real problem.

So, what will they tend to do? A correction. They will reposition what has deviated, so that the logo looks good again… for now.

And what do they tend to forget? The corrective action — making sure it doesn’t happen again by eliminating its root cause.

1. Obstacles to root cause analysis in Chinese factories

Corrective actions take time and brainpower. It usually involves a discussion with operators, who probably know the machine’s behavior much better than engineers do. It requires observation, experiments, and followups (I described an excellent approach in this article)… While the container needs to get out the door tonight!

But the main obstacle, I feel, is cultural. I can’t put my finger on it, but there is something in the Chinese education system and/or culture that drives a lack of interest in long-term solutions.

2. Poor understanding of the usual root cause analysis methods

You can teach the “five whys” of the “fishbone diagram” tools to Chinese engineers, but it will take them a LOT of time to apply them in the right way.

A frequent mistake is to designate a worker’s lack of discipline as the root cause. And to avoid going further (is this really lack of discipline? Or poor training? Or poor work standards?…), which makes it ineffective in driving improvement.

3. A really nice tool for root cause analysis

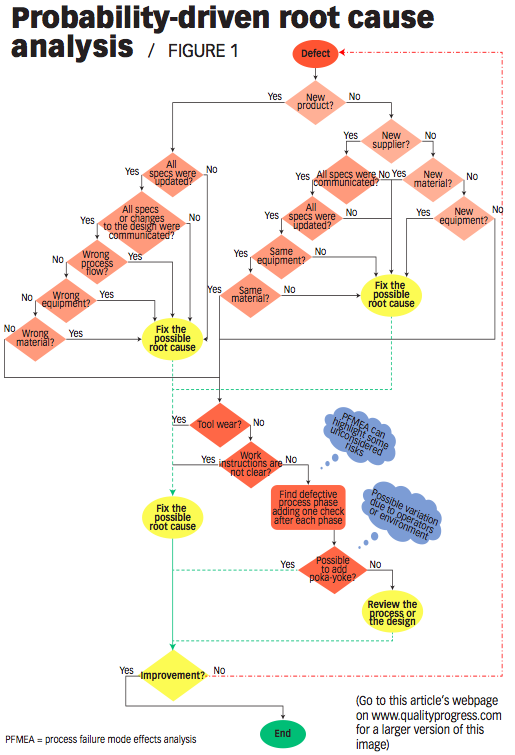

I just found a nice flow chart in an article (“Probable Cause, Using probability to get to the bottom of the issue”, published in Quality Progress of Sept. 2013 by Moreno Broccoletti — registration required):

I think this flow chart can be very useful in Chinese factories for 2 reasons:

- It is simple and graphical.

- It puts the finger on the right type of issues (for example, “specs that were not updated” means the document control procedure is missing or not followed — the management system is the problem, not a random worker’s attitude).

What do you think about this tool?

0 Responses

Good observations. I had read the QP article with this method, and it makes a lot of sense; by focusing on the most frequent problem causes, the problem-solving effort can be made a lot quicker.

Looking back to the earlier point, I have also been frustrated with Chinese suppliers who do not seem motivated to do root cause corrections. But, I would have to add that we have our

share of such folks in the USA, too. We are getting better at it in part because our customers have raised the stakes for shipping nonconforming products– doing containment inspections, repaying warranty costs, etc, etc,… Even so, some of my US colleagues still don’t get it. And in automotive, we’ve been preaching root cause problem solving since the 1980’s.

Brad

Thanks Brad for giving some perspective on this.

Nice diagram.

Brad, do you have this in a Chinese version?