When I started doing inspections, I purchased a licence to the ISO2859-1 standard before I even received the first payment from my client. Working on the basis of irrefutable statistics appeared to be indispensable.

When I started doing inspections, I purchased a licence to the ISO2859-1 standard before I even received the first payment from my client. Working on the basis of irrefutable statistics appeared to be indispensable.

It seems like the cost for a single licence (192 CHF–about 200 USD) is still too much for many established quality control firms. They don’t even use the right tables to determine how many samples they should select!

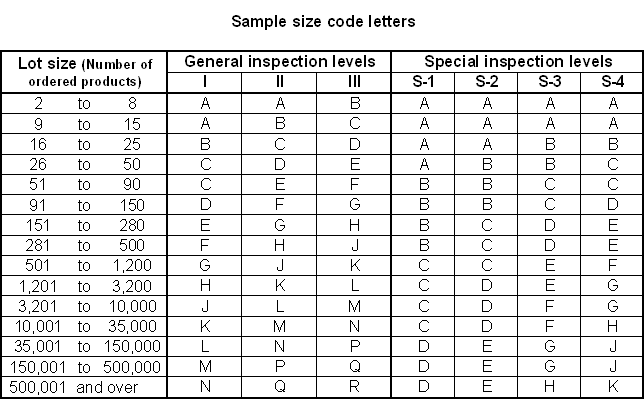

Here is one example (for clear explanations of the key terms, refer to my page about quality control basic concepts): the order quantity is 2,000 pieces, and the inspection should be in reduced level (I).

The first step is to get the correct letter: H (see the below table: row: “1,201 to 3,200”; column: “I”).

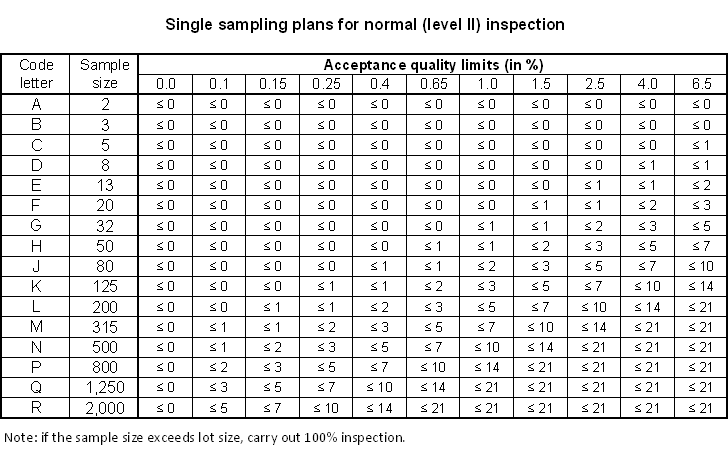

Then they MISTAKENLY use the table for normal level (II), as below:

So they conclude that they should select 50 samples. WRONG!

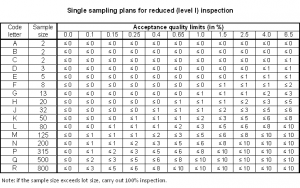

This is the table they should use:

The correct answer is: 20 samples.

The correct answer is: 20 samples.

I noticed that several inspectors, including some coming from the largest QC firms, made this mistake. I was thinking they had never really grasped the statistics because their office was preparing sampling plans for them.

I really started to scratch my head over this issue when a long-time client of mine asked why my sampling plans were “wrong”. I double-checked the standard and confirmed my numbers. Finally I had to send them screenshots of the standard to calm their doubts.

Then I looked at what other QC firms do. It seems like everybody is doing it wrong (from what I checked). Can’t they work with 4 tables? Is it too many?? I am really surprised… Or maybe there is something I don’t get?

+++++++++++

UPDATE: all my apologies, I was mixing up two concepts (levels vs. severity). See clarification on https://qualityinspection.org/statistical-inspection-levels/.

2 Responses

Hi Guilhem, thanks for the comment… I’m glad I’m not the only one who thinks everyone else is wrong 😉

Excellent finding Renaud. I have been in QC industry in China for over 3 years and it is the 1st time someone explains the AQL tables properly and especially the reduced and tightened levels of inspection.

99% of people will simply apply G-I for reduced (or G-III for tightened) on normal inspection table, which is a big mistake. Each level, reduced, normal and tightened have their own table to refer to!

In fact most of QC companies never really studied the standard ISO 2859-1 they claim they comply with… Fascinating!