The number one challenge of Chinese suppliers is price, as revealed by a recent survey. Their costs keep rising, but price competition is stronger and stronger.

The number one challenge of Chinese suppliers is price, as revealed by a recent survey. Their costs keep rising, but price competition is stronger and stronger.

Factory owners spend a lot of time trying to reduce costs. Unfortunately, they tend to focus only on three levers to keep their costs under control:

- Negotiating down material prices;

- Limiting salary raises;

- Pushing the employees to work hard, for long hours.

These are actually NOT the main drivers of cost though…

Chinese factory owners are missing the major cost drivers in their own factories!

Here is how to reduce costs in a factory by 15-25% after one year of re-organization:

- Simplifying the flow of materials through different processes;

- Improving the way each process step is conducted.

The key is to eliminate as much waste as possible.

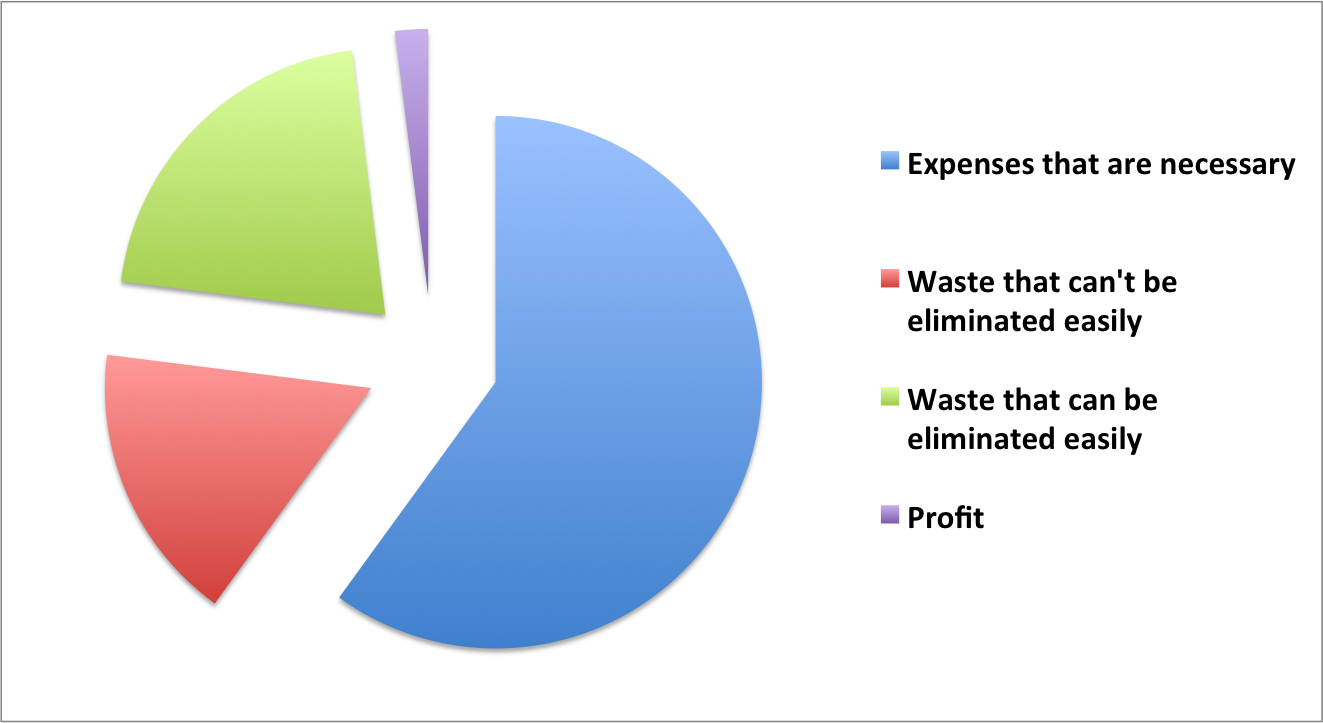

The cost structure (and the very thin profit) of a typical manufacturer:

What is “Waste that can be eliminated easily”?

Taiichi Ohno, the father of the Toyota Production System, listed 7 types of waste that can be found in every factory.

Eliminating waste completely is virtually impossible. But a good part of it can be eliminated easily.

I listed the 7 categories of waste below. All of them can be reduced by 50-90% within 1 year.

- Transportation: moving materials or products from one place to another, simply because the different steps of a production are not side by side.

- Inventory: the company’s cash is tied up in inventory that sits still most of the time and that necessitates lots of warehousing space.

- Unnecessary motion: process steps that don’t add value to the product, such as walking to pick a bin of products.

- Waiting: operators who can’t work because they are waiting for materials or because their machine has broken down; products waiting for weeks in a queue.

- Over-processing: spending some time/energy that is not necessary during a process. (Maybe no work instructions exist, maybe they are not adequate, or maybe they are not respected).

- Over-production: producing more than current orders call for, “just in case”. It might stay in inventory for a long time and lose value.

- Defects: processing some material in a way that is not satisfactory. I already detailed the costs of defects before.

So, how to reduce all this waste? The production organization needs to be completely modified.

Factory managers need to grasp some counter-intuitive concepts

Is it cheaper to make 1 piece at a time, or 10,000 pieces at a time?

Everybody thinks “10,000 pieces at a time”. And they have been proven wrong by many studies. A fun simulation on this topic can be watched here on Youtube.

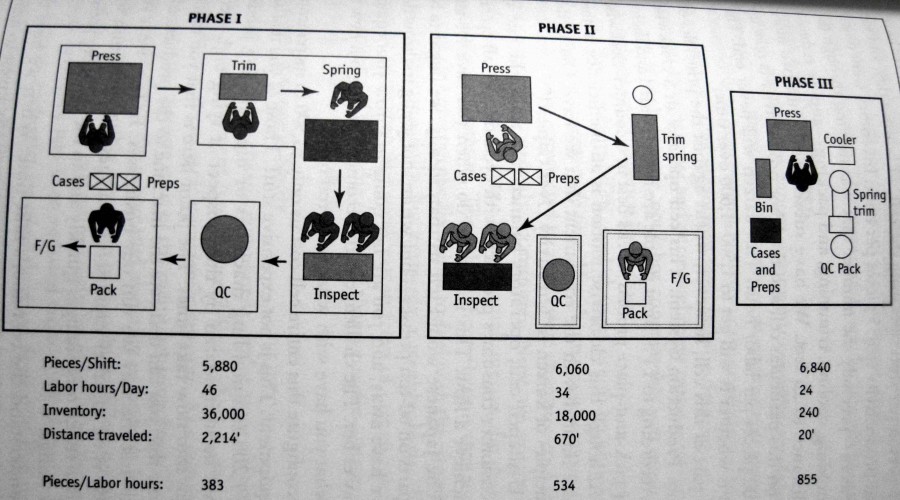

Here is a real example where this logic was taken to the extreme — with great success. It is described by the CEO of Freudenberg-NOK (a manufacturer of sealing components) in an excellent book called Becoming Lean: Inside Stories of U.S. Manufacturers.

Initially, they had several disconnected and distant processes. They moved progressively toward making 1 piece at a time. Here are the results:

These are impressive and very counter-intuitive results, aren’t they?

One-person cells, like in this example, are pretty rare. But they are not necessary for processing 1 piece at a time. Even the cell shown in “phase II” is vastly more efficient than what I see in 99% of Chinese factories.

Note: switching to phase II or to phase I necessitates cross-trained operators who work on well-maintained and right-sized machines/equipment. It does not necessitate large capital investment, but a lot of training and new habits.

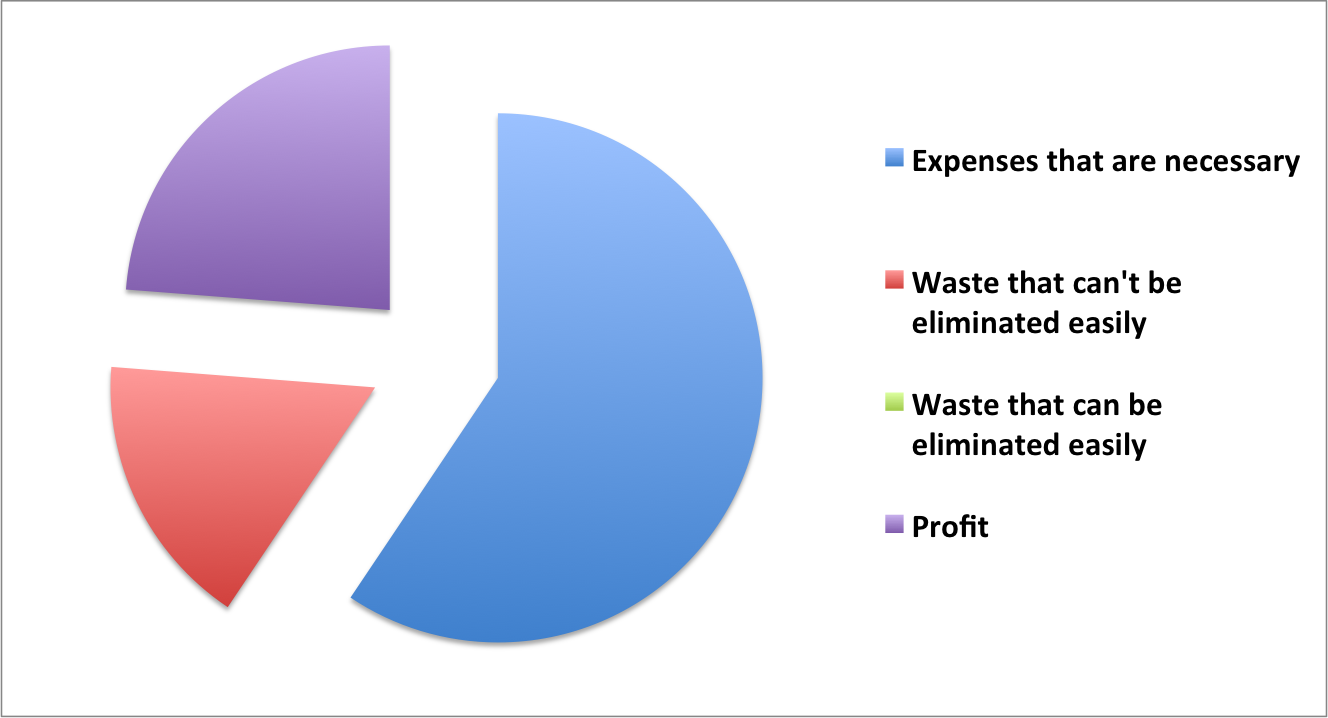

What happens when a good part of the waste is eliminated?

If prices are maintained constant, the profit margin will be much higher:

Prices don’t necessarily need to be reduced since customers will reap a lot of benefits: higher quality, shorter lead times, lower MOQs… Actually, sales typically go up in these situations!

—

How have you reduced costs in factories? Have you got any experiences to share about waste-elimination initiatives that succeeded or failed? Let me know by leaving a comment.

Ultimate Guide To Sourcing From China And Developing Your Suppliers [eBook]

This FREE eBook starts from the beginning, discussing whether you need to hire a sourcing agent, and follows the sourcing process right through to developing a trusted supplier’s quality and productivity.

There are 15 chapters over 80+ pages to explore, providing exhaustive guidance on the entire sourcing and supplier development process from start to finish, including:

- Identifying suppliers,

- Negotiations,

- Quality inspections,

- Developing Chinese suppliers,

- Improving factory quality and productivity,

- and much more…

little bit long article. I really like your first paragraph .