E-commerce expert and host of the popular 'The Seller Process' podcast, Gianmarco Meli, shares his advice for SMEs who import products from Asia about building better systems and processes for your company if you're selling online via … [Read more...]

How The Taguchi Method Leads To Consistently-Manufactured Products

The Taguchi method is a tool used in engineering and manufacturing to improve product and process quality and reduce defects at an early stage. It is a statistical analysis approach used early in the product development process that reduces … [Read more...]

“Checklist Manifesto” | Improving New Product Introduction & Routine Manufacturing

I recently read The Checklist Manifesto: How to Get Things Right by Atul Gawande, a surgeon with a strong interest in process improvement. It's a great book about the value of multi-disciplinary reviews at certain stages of a project and … [Read more...]

Assembly Fixtures: A Valuable Productivity and Quality Tool

Assembly fixtures are very important tools used in the factory to provide better quality, faster, and cheaper production. Almost every importer will like the sound of those benefits! Checking fixtures are similar, but they … [Read more...]

Process FMEA: Template, Use Cases, and Examples

The Process FMEA is so useful... and so poorly conducted a lot of the time. There is an art to it, just like there is an art to conducting a solid root cause analysis. It seems to be quite a difficult and unnatural exercise for most … [Read more...]

What’s a Supplier Development Program, and Why Implement One? [Podcast]

In this episode… Let's say you're now working with a new supplier who’s doing your manufacturing in China (or elsewhere in Asia). No doubt some things will be great, and there may be issues that you wish could improve. Rather than … [Read more...]

How To Improve Supplier Performance? [Podcast]

In this episode... Renaud talks you through a common query that we get on a regular basis when customers ask us: "How do I get my suppliers to improve?" A recent survey of importers found that 70% said that their biggest challenge was … [Read more...]

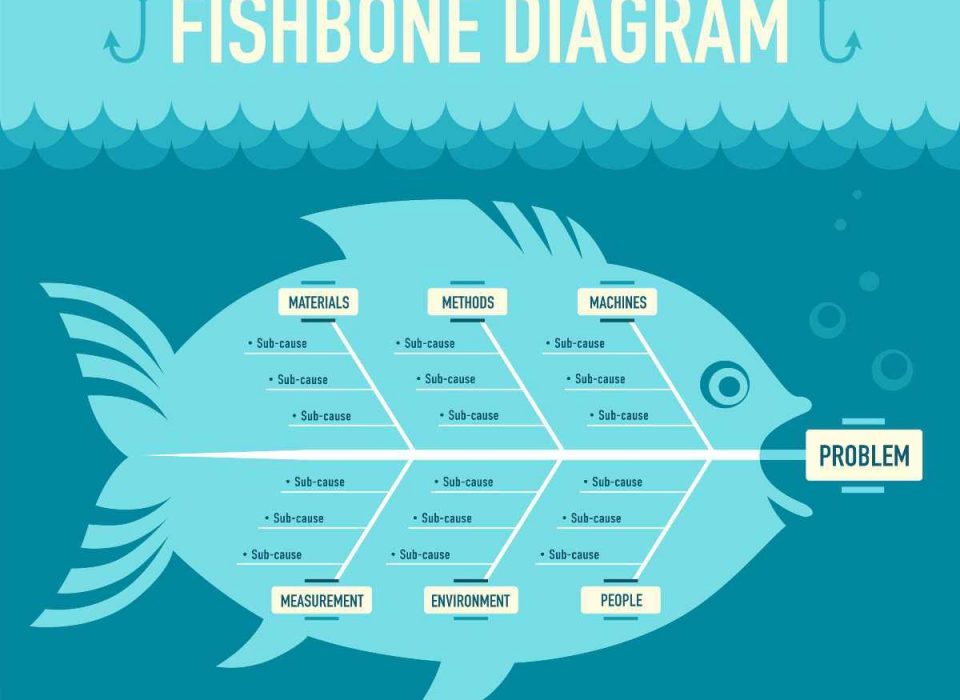

An Introduction to Root Cause Analysis (Not Just for Manufacturing)

One of the most frustrating aspects of working with Chinese suppliers is that, for the most part, they don't want to (or cannot) conduct a root cause analysis. Let's say you found a serious issue in one of your productions and you don't … [Read more...]

Defining and Enforcing Manufacturing Processes for Better Control

As David Collins from CMC often says, there are 5 key success factors that determine a factory’s performance: Production Planning, Incoming Material, Workforce Training, Process Control and Equipment Maintenance. In this article, I'd … [Read more...]

How To Fill Out an 8D Report and Fix a Problem in a Factory

Filling out an 8D report means following a highly-structured approach to understanding, addressing, and (in the future) avoiding a problem. It is particularly effective for issues that are important and relatively complex. … [Read more...]

![What's a Supplier Development Program, and Why Implement One? [Podcast]](https://qualityinspection.org/wp-content/uploads/2022/04/WhatsaSupplierDevelopmentProgramandWhyImplementOnePodcast-960x630.jpeg)

![How To Improve Supplier Performance? [Podcast]](https://qualityinspection.org/wp-content/uploads/2021/06/HowToImproveSupplierPerformancePodcast-960x627.jpeg)