One of the major fears of importers is to notice substandard components when they receive a batch from China. But how to reduce the risks of receiving them from your suppliers?

Substituting the parts you require for cheaper ones…a common ploy

Unfortunately, substituting cheaper parts is one of the favorite tactics of Chinese manufacturers. That’s the fastest way to save serious money. And who knows, this customer probably won’t notice it, right?

Controlling that is not easy, as I wrote before in Are Your Chinese Factory’s Batteries Made by Samsung, LG, or Panasonic?. In some cases, the markings are identical to “the real thing”, and testing is not sufficient to eliminate all risks.

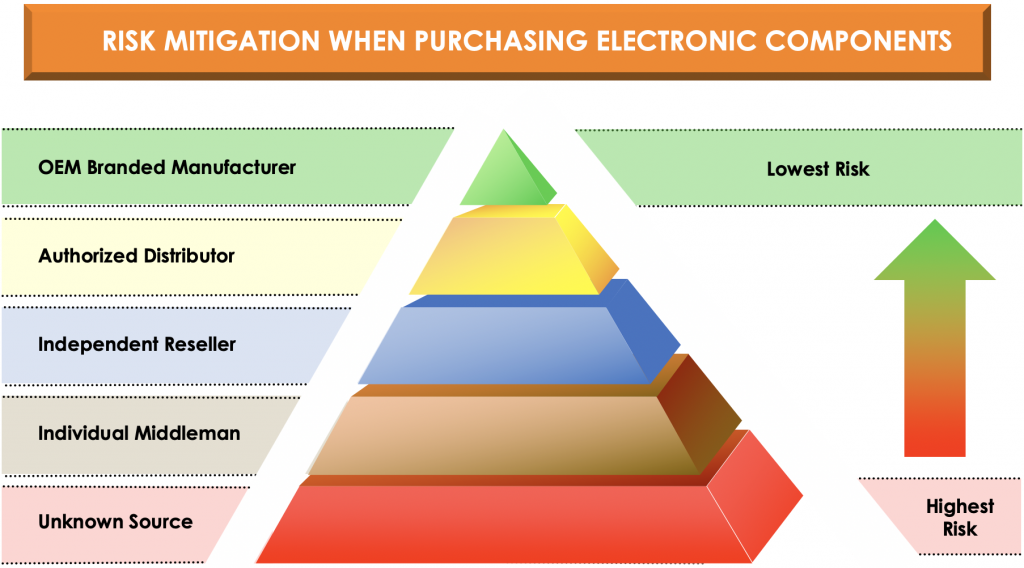

In the end, the only real solution is to control your supply chain tightly. It can be illustrated this way:

In Electronic Product Compliance in Practice (a great in-depth article), my partner Fabien responded this way to the question “How do you ensure that components, such as AC adapters and lithium batteries, are compliant?“:

In short, know your supply chain.

As mentioned before, you as the buyer are responsible for verifying the products you sell are safe to use. That said, there are steps you can take to reduce the risk of buying products that do not or will not meet compliance tests.

The safest way to purchase directly from the OEM manufacturer, who would be able to carry out test and certify their products, particularly if that OEM were an established brand such as TDK for power supplies or Samsung for battery cell.

The further away from the OEM in the supply chain, the greater the risk.

If you let your manufacturer buy from local suppliers, you need to ensure they are compliant with the strictest regulations. For example, lithium batteries should be at least UN38.3 compliant, IEC62133 is recommended, and the best would be to comply with American standards UL1642 and UL2054.

Another example: for AC adapters, it is better to keep your focus on UL and FCC approved products and avoid cheaper options (the risks are sparking at plug-in, lack of short-circuit protections, and so forth).

Remember to obtain product technical data sheets for all critical items on the BoM

One more tip to ensure your components or product is compliant is to obtain product technical data sheets for all the items on the BoM. This way you can check specific details, including any certifications obtained through regulatory testing.

If your supplier doesn’t give you that information, in the long run, you will be better off working with another supplier that does.

However, in case a custom component is manufactured to your specification, it is your responsibility to know how to test it. (This is also true at the final product level — make sure a custom product tested, even though all the components used to assemble it are compliant on their own.)

****

Any experiences to share on this topic? Do you simply trust your suppliers? Do you try and work only with large assembly facilities? Do you carry out some random testing?

Sofeast: Quality Assurance In China Or Vietnam For Beginners [eBook]

This free eBook shows importers who are new to outsourcing production to China or Vietnam the five key foundations of a proven Quality Assurance strategy, and also shows you some common traps that importers fall into and how to avoid or overcome them in order to get the best possible production results.

Ready to get your copy? Hit the button below: