In the last publication of “Connexions”, the magazine edited by the French Chamber of Commerce in China, I found an interesting survey (conducted by IFOP Asia) of French companies established in China.

In the last publication of “Connexions”, the magazine edited by the French Chamber of Commerce in China, I found an interesting survey (conducted by IFOP Asia) of French companies established in China.

Here are the most interesting data:

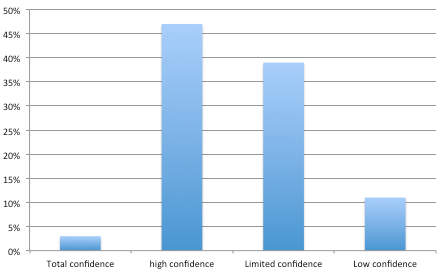

How would you qualify the relationship you have with your main suppliers?

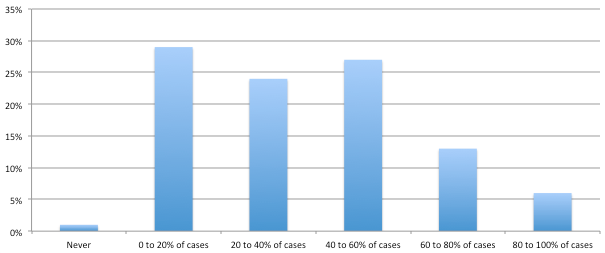

In which proportion do you run into quality problems with your Chinese suppliers?

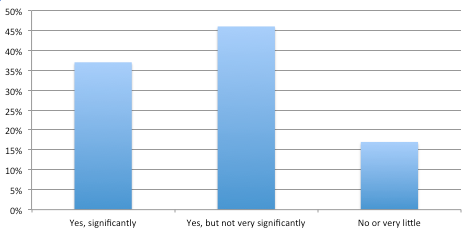

Would you say that quality offered by Chinese suppliers tends to improve?

The survey also reveals more qualitative insights:

- The main problem of China suppliers is their lack of organization.

- Instead of improving their suppliers’ organization, buyers tend to conduct quality control.

- As a consequence, manufacturers lose a sense of responsibility, as they get used to constant supervision. It seems like many buyers share this feeling.

- Quality tends to improve, and this is directly linked to increases in labor costs. Re-working defective products costs more and more, and is less tolerable to manufacturers.

- A good practice is to set up a close partnership with a few key suppliers and to help them improve. It takes time but it is key in the search of better quality.

What do you think?

—

Message for RSS subscribers

If you use Google Reader to follow new articles, you’ll need to switch before July 1. Feedly is a good option and offers a one-click Google Reader import. Their migration instructions are here: Tips for Google reader users migrating to feedly.

Nice to see that 85% of the buyer consider that they suppliers are improving.

Yes, I was surprised by that stat.

I hope it does not mean that the suppliers were so bad at the beginning (just joking)

Maybe it does 😉