Let’s say you want to follow the general procedure for quality inspections. How many samples should you draw for inspection?

Let’s say you want to follow the general procedure for quality inspections. How many samples should you draw for inspection?

Let’s also say you want to follow the ISO 2859-1 standard, under normal severity, and in level II. (If you are not familiar with these concepts, you can read the articles listed under Quality Control Basics).

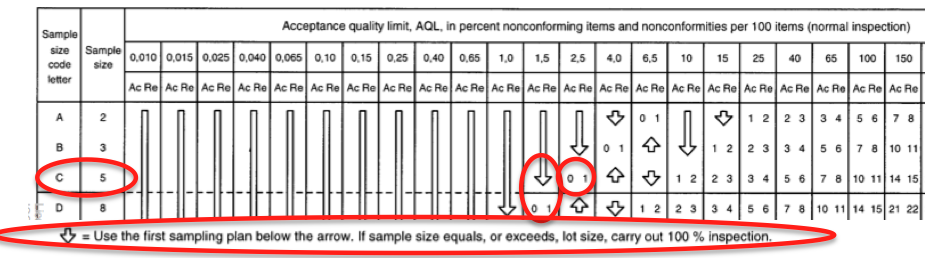

It is fairly easy to read the AQL tables and to see what the number of samples to inspect is…

… Except in certain situations, in particular when your AQL limits are low and your sample size is low. You might have to select different numbers of samples for each category of defect.

Let’s walk through two examples to illustrate this.

Case 1:

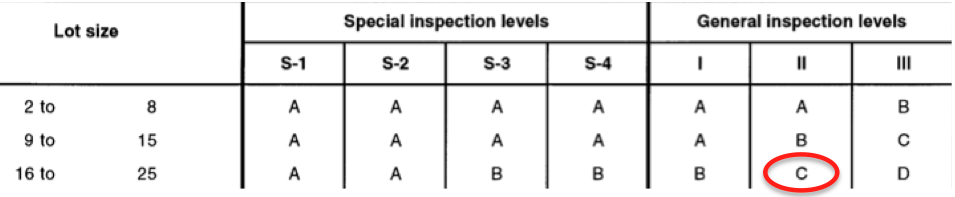

Order quantity is 20 pieces. Level II, normal severity. AQL is 1.5 for major, and 2.5 for minor.

The letter is C:

The inspector draws 8 samples at random, and the batch is rejected if he finds at least 1 defect in any of the 2 categories. It means there are 3 samples that are checked for major defects but that are not checked for minor defects.

Case 2:

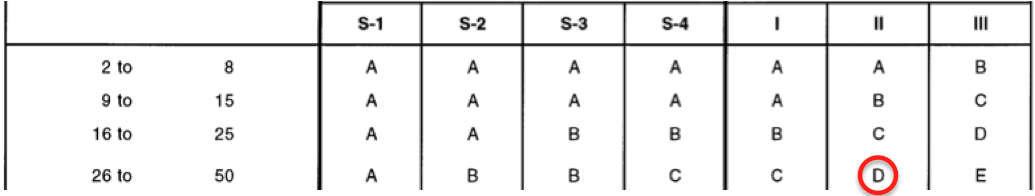

Order quantity is 30 pieces. Level II, normal severity. AQL is 2.5 for major, and 4.0 for minor.

The letter is D:

The inspector draws 13 samples at random. For major defects, only 5 samples are checked, and the batch is rejected if 1 or more defects are found. For minor defects, 13 samples are checked, and the batch is rejected if 2 or more defects are found.

This is one of the details that many people in the industry tend to overlook. Yet it is indispensable if one is to apply these statistical rules correctly.

On a similar subject, you can read Statistical inspection levels: beware of the confusion.

The ISO 2859-1 standard section 10.3 does give you the option to use the larger sample size for all the inspections. So in your case 1 the 8 sample can be used for both the major and minor inspections. In case 2 you could do the major and minor inspection on the 13 samples.

Norman,

I guess you are referring to this paragraph, right?

“When no sampling plan is available for a given combination of AQL and sample size code letter, the tables direct the user to a different letter. The sample size to be used is given by the new sample size code letter, not by the original letter. If this procedure leads to different sample sizes for different classes of nonconformities or nonconforming items, the sample size code letter corresponding to the largest sample size derived may be used for all classes of nonconformities or nonconforming items, when designated or approved by the responsible authority. As an alternative to a single sampling plan with an acceptance number of 0, the plan with an acceptance number of 1 with its correspondingly larger sample size for a designated AQL (where available) may be used, when designated or approved by the responsible authority.”

Norman,

So, the standard tells us that we “may” use the same sampling size. Or we may not.

What would you advise?