It seems nearly every major retailer has given some thought to letting their suppliers check quality themselves. I wrote about it in Why Supplier Self-Inspections Are Getting More Popular in China.

The obvious benefit is cutting costs. No need to send someone to the factory before every shipment.

Another benefit is, when this works well, to stop “baby-sitting” suppliers and to force them to take responsibility for important matters such as product quality… And, hopefully, incentivize them to do a good job.

However, this approach is fraught with risks and needs to be planned carefully. I listed some of these risks before (Limits of Letting a Supplier Self-Inspect their Product Quality):

- Factory doesn’t use the same inspection/testing method

- Factory doesn’t use the same inspection/testing instruments

- Factory takes liberties with sampling (e.g. re-doing a test on the same sample until it passes, or picking new samples to replace those that don’t pass)

- Factory writes a report ‘to keep the customer happy’. This cynical approach is unfortunately very present in China, and it is not unheard of in India or Vietnam!

As you can see, there are many ways things could go wrong!

How to go from “inspect 100% of this factory’s batches” to “inspect 0% of their batches”?

Most buyers base their decisions on three elements:

- Supplier past performance (‘we haven’t had big issues with them recently’)

- A risk analysis (‘this product category is not very sensitive’)

- A good dose of hunches (‘it feels right to this way’).

However, going from 100% to 0% is quite abrupt. There needs to be a transition.

What most people don’t know is, the ISO 2859-3 standard includes statistics that can guide you to check only, for example, 25% of a supplier’s batches for a given product. If an inspection fails, it directs you to go back to checking every back, and then it gives rules for going back to a skip-lot approach. This is a great intermediary stage between “check 100% of batches” and “let it go completely”.

Stage 1: Select candidates

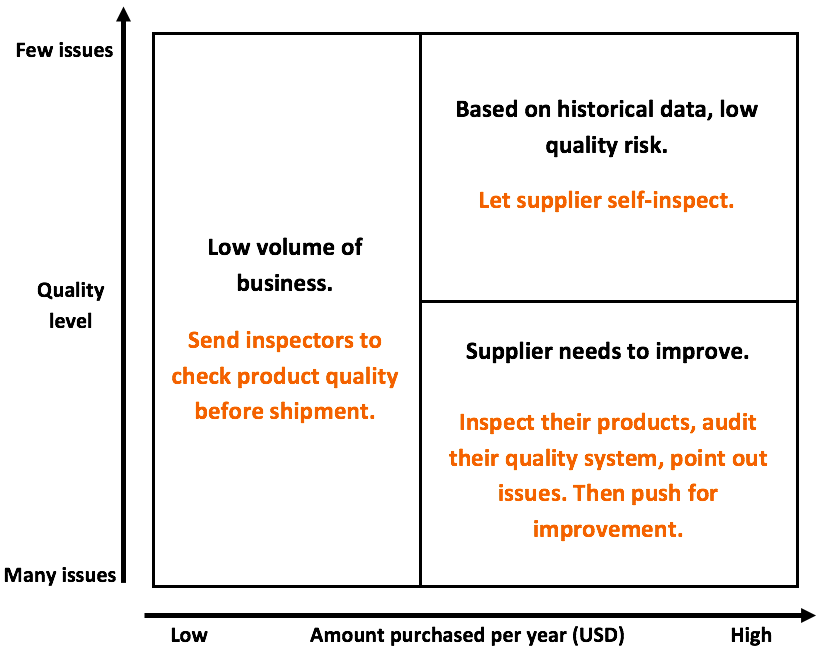

Here is an example of 2×2 table that can help you identify the best candidates (in the upper-right quadrant).

Stage 2: Confirm they know what they are doing and they have the right attitude

First, you can probably know right away if they have the right attitude. Ask purchasers about these points:

- Do they tend to subcontract to different outside facilities?

- How honest are they when responding to claims due to poor quality?

Second, you need to send an auditor or an engineer to the factory and evaluate:

- What type of products are they best at? (Don’t give them a license to ship all types of product without inspection.)

- Do they have all the basic good-practice systems and processes, when it comes to purchasing, manufacturing, and warehousing?

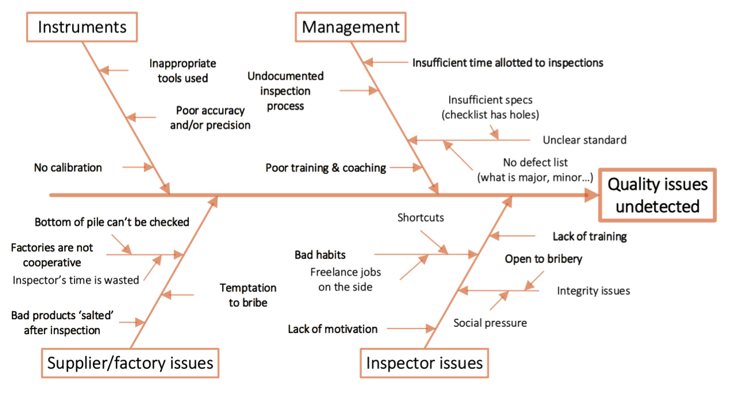

- Do they do their inspections the right way? I drew this fishbone diagram before — see for more in-depth analyses on human factors, supplier behavior, QC management, and QC instruments.

You will certainly eliminate some candidates based on your findings in this stage.

You will certainly eliminate some candidates based on your findings in this stage.

Stage 3: find the model that works for your company

There is no one-size-fits-all approach here. You will need to test & refine the right combination of these elements:

- Sampling – will they have to check 100% of the goods, or just a sample (and should it be based on the AQL tables)?

- Training and on-site coaching of the factory’s inspectors – they need to know your standard, to be able to follow the right method, with the right tools, and so on.

- Auditing and monitoring – you probably can’t let them handle it without any help and without any constraints. Training and authorizing/certifying a few of their QC employees is important. How much of this can be through e-learning, and how much has to be on site?

- Claims handling – what if a supplier reports all is good and then, 2 months later, a very widespread & obvious issue is found?

- Transition period – do you want to follow a skip-lot sampling plan as I suggested above? At what point do you feel confident to “let it go” entirely.

It means you need to start with just a few suppliers and make adjustments.

If you want to have a view over the suppliers’ inspectors’ work, you can use QC reporting software (links to an infographic that shows the main benefits of our software).

Stage 4: roll it out to all candidates who were identified & kept after stage 2

Once you are confident you have a good model, roll it out to other suppliers over time. And keep the pressure on! Factory staff sometimes turn over very fast… And they might not be fully isolated from business considerations.

—

Have you got any feedback about self-inspections? How did it go for your company?