As 2019 draws to a close it’s a great time to sit down and look at some of our most popular blog articles and resources from the last year.

We also hope that you’ll stumble across some great topics that you’d otherwise have missed.

2019 was a great year here at QualityInspection.org as we:

- Celebrated more than 10 years of blogging! (Take a look at my very first post from 2009)

- Revamped our website, giving it a fresher look with more information to help you!

- Published another 85 posts to add to our total of over 1,100 totally free posts

- Partnered with our company, Sofeast, to provide their many useful manufacturing & importing resources to you (a whole library filled with free guides, eBooks, webinars, and more all made to help you improve your results)

- Built our new LinkedIn page (have you followed us there yet?)

- Launched our QualityInspection.org YouTube channel which has lots of videos filled with tips to help you improve or understand certain topics better (remember to subscribe)!

I’m always striving to deliver the topics and information that YOU want to understand more about from the world of manufacturing, with a focus on China, QC, sourcing, supply chain management, and more! That’s why I need your help – please contact me and let me know what you’d like me to write about in 2020 and beyond!

Our 10 top manufacturing articles of 2019

OK, it’s time to dive into our 10 top articles from this year (the most popular with our readers in ascending order of views, mainly published in 2019, but a couple of classics are in there, too).

10. 9 Things Only a Large Company Can Obtain in China/Vietnam

There’s plenty of advice out there aimed at importers sourcing products from China, Vietnam, or other low-cost Asian countries, however much of it is NOT applicable to companies buying under 20 million USD a year and, sometimes, not under 1 billion USD a year. To raise your awareness, I made a list of 9 things large importers can get, but small companies usually can’t negotiate… Read More

9. Continuous Auditing to Keep Pressure on a China Factory: How it Works

One of the questions our clients over at Sofeast ask most often is: “How to keep the pressure on our supplier’s factory so they improve and they don’t make the same mistakes again”. Continuous auditing is an answer to this, but how does it work? … Read More

8. 28 Common Problems Chinese Suppliers Cause Importers

I was thinking of the most common problems Chinese suppliers cause for importers, especially those developing their own products. I noticed something interesting. Most of them all linked to the way information is managed. So, to help you avoid these problems, I made a categorized list so you’re aware of them… Read More

7. Why Design Defects Are Behind Many Quality/Safety Issues

There is a tendency for inexperienced importers to blame their suppliers for all quality and safety issues that come up.

However, in the situation where the buyer works with an OEM or a contract manufacturer, they share some (and usually all) of the responsibility when something goes wrong. In these cases, it may well be that manufacturing or design defects are the cause. What are these defects and how do we minimize them? … Read More

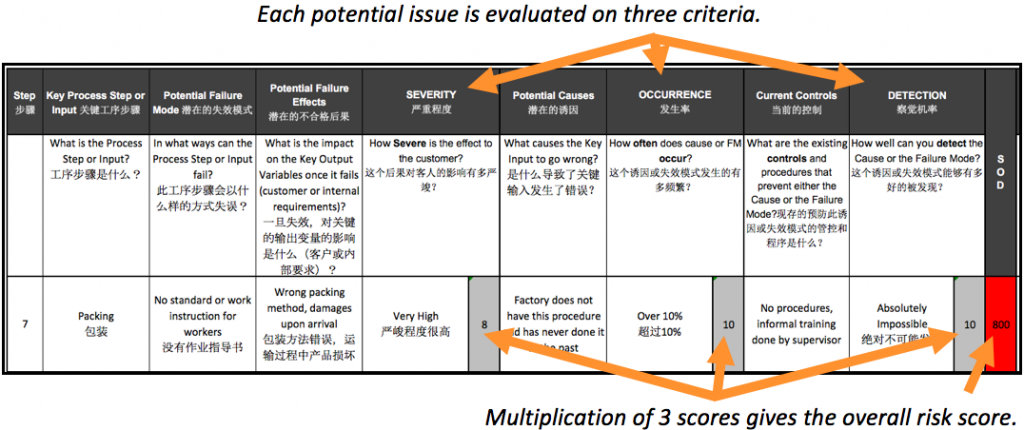

6. The Process FMEA: Template, Use Cases, and Example

In this classic post, which has continued to be a firm favourite in 2019, I explain what a Process FMEA is, provide you with a template, and explain how to fill it out. Ready to perform yours? … Read More

5. Factory Audit Tips: 10 Signs of a Bad ISO 9001 Implementation

How to spot a bad ISO 9001 implementation in a factory? There are many signs, and I listed ten of them in this post so you can pinpoint if a manufacturer is applying it correctly or not which may influence whether you wish to work with them… Read More

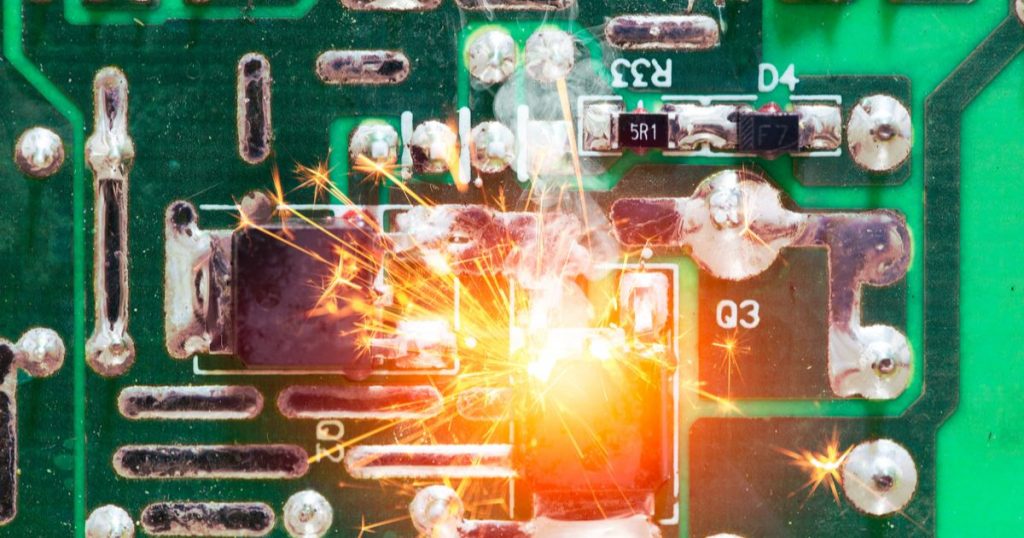

4. Reliability Testing on Electronic Products in China: Don’t Skip It

We have worked with many companies that have designed an electronic product and had it manufactured in China, yet they tend to have a common blind spot: running reliability testing on electronic products. In this post, I’ll show you how testing your electronic products in extreme (but realistic) conditions until they fail is possible and important… Read More

3. QC Basics: What is a Quality Inspection? Context, Tools & Template

One of our all-time favourite posts, this article answers the question: ‘What is a quality inspection?’ and explores when they typically take place (before, during, and after production). We updated it a lot this year to make it really exhaustive, so if you’re interested in learning more about quality inspections, this is the post for you… Read More

2. The Danger of Developing your Custom Product with an ODM Factory

Many people who have a great idea to improve on an existing product are often tempted to go for a shortcut: working with a manufacturer that has been making very similar products (an Original Design Manufacturer, or ODM) before. But this is where it gets risky for them! I explain the pros and cons of working with ODMs to develop your new product idea … Read More

1. How To Keep A Clean Factory And Stop Dust On A Budget

This blog post with actionable advice took this year’s top spot, and why not? Dust contamination affects most manufacturers! In fact, in many industries, one of the most common reasons for defective goods is dust contamination which occurs in the factory itself. I share with you the 80/20 of air cleanliness in factories so you can stop dust without spending a fortune … Read More

Top Videos from 2019

Here are a couple of videos which viewers particularly enjoyed this year:

Reducing Your Quality Risks: Advice For Importers In China

How To Read The ANSI Tables For Inspections Based On Random Sampling

Our senior engineer explores common production processes and materials

Over at Sofeast, we also provide a vast number of videos where our senior engineer, Paul Adams, guides you through the many production processes and materials that we work with on a regular basis. This knowledge is put out there to help you to understand what your products are made from, how they’re being made, and how best to test them.

Take a look at the different categories on offer and select the ones you want to watch here or by hitting the image below:

*****

See you in the 2020s!

I’d like to wish a huge thank you to everyone who read, contributed to, or shared any content from QualityInspection.org in 2019!

As QualityInspection.org completes its first decade, I am really grateful that you’ve joined me on this journey to share knowledge and improve everyone’s manufacturing, quality, and sourcing results from China and beyond. I’m excited to see where the next decade takes us!

Until then, best wishes and a Happy New Year! 🎉