As I wrote before, preventive maintenance helps cut costs and improves quality. That’s an extremely important element of good manufacturing and it doesn’t get much coverage.

Simply put, it extends the lifetime of the equipment, it prevents downtime that prevents production from taking place, and it ensures the equipment is ready to make good products.

I have seen many factories set up a standard schedule for some operations (e.g. check the oil levels once a week, change the filter every 2 months). That’s the most basic aspect of preventive maintenance (PM).

A slightly more advanced PM plan gets closer to a process control plan. And for good reason. There is an enormous overlap between them.

Good equipment & tooling is an integral part of process control. Cleaning, checking visually, adjusting, repairing, and replacing are needed. You will have to do it anyway when the production staff comes shouting “the machine is down, we can’t many anything” (that’s “reactive maintenance”).

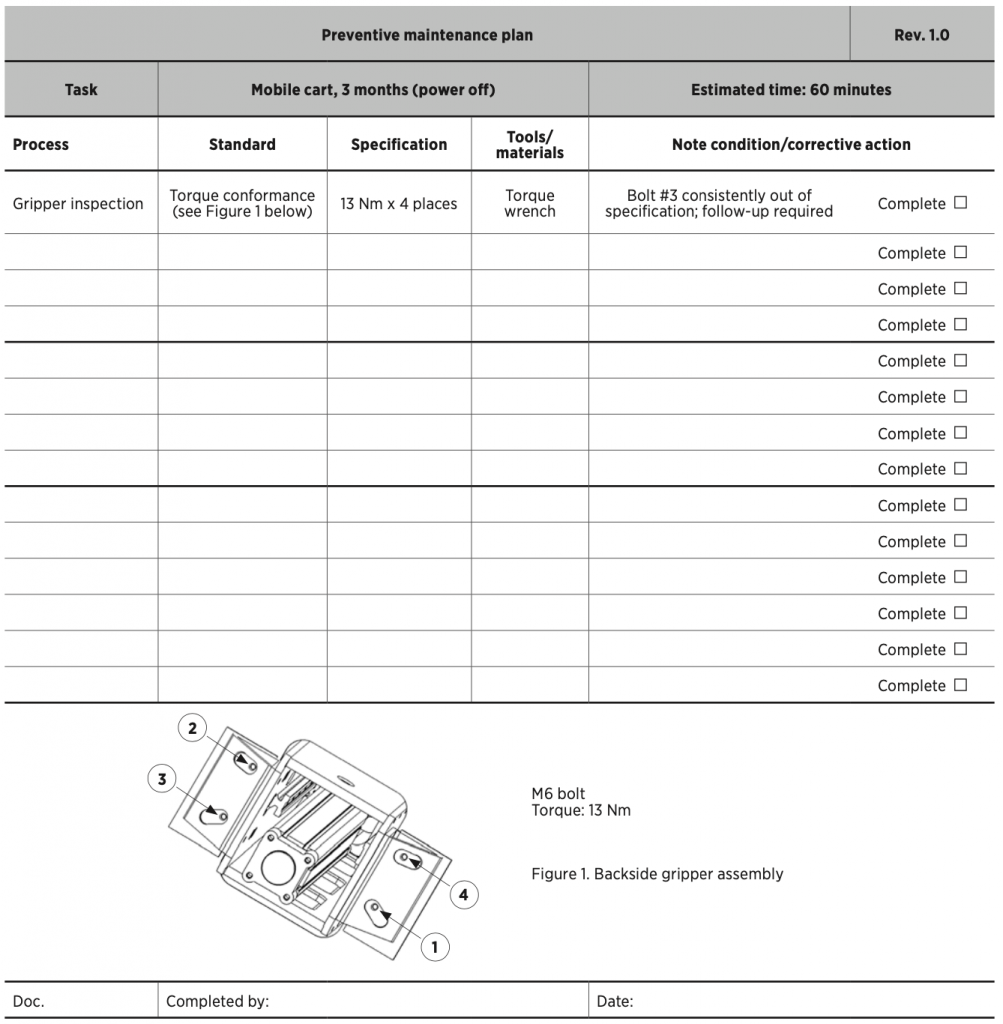

1. A nice preventive maintenance example

In Teaching New Dogs Old Tricks (behind a paywall), Juan Ernesto Rodriguez, who works on equipment reliability for Boeing, suggests using a simple template.

Aircraft manufacturers are at the bleeding edge of reliability engineering and asset maintenance in general. Let’s look at their example of a PM plan.

Why is it a nice example?

This is a plan for 1 piece of equipment. I like it for several reasons.

- It is visual. The technician (or the skilled operator) can see where bolt # 3 is located. No guessing, easy to read. These people usually don’t like reading big blocks of text.

- It is structured. Show an example and give a template, and several engineers will produce the same result. When all the plans are structured the same way, misunderstandings and training costs go down.

- It is very specific – there is no general wording such as “check and confirm”. The ‘standard’, “specification’, and ‘tools/materials’ columns force the write to be concise and specific.

- It is organized by process. This way, ideally, PM can be organized so the most critical process steps are addressed in priority. There is not always enough resources to do everything, but some jobs really, really need to get done as planned.

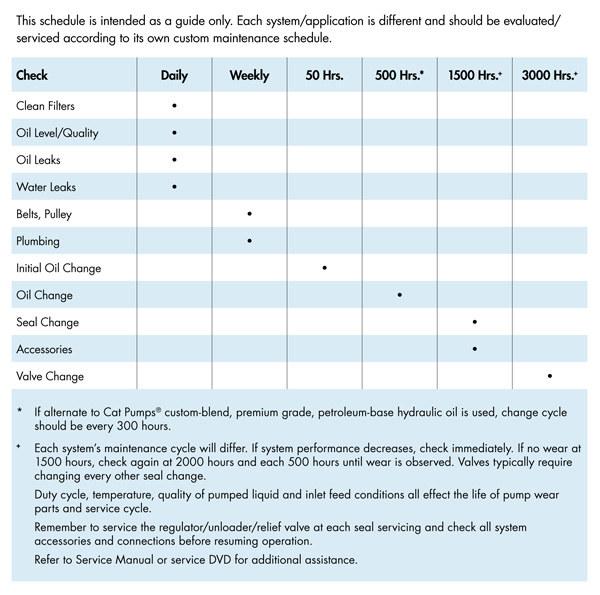

2. A simpler, but probably less effective, example of a maintenance plan

I found this simple example at https://www.catpumps.co.uk. It is typical of what manufacturers typically provide to their customers. “Do this and our equipment will run optimally”.

It is a good basis for developing a more structured plan, but I don’t think it should be adopted in this form.

Implementation challenges

I am fully aware that most Chinese manufacturers adopt a reactive approach to all aspects of their operations:

- Fix the products when the customer’s inspectors reject a batch

- Give a price break when a customer is about to leave

- Repair a tool when it breaks down

- Give a pay raise when employees are complaining (or not coming back)

- And so on, and so forth.

However, once the boss understands the link between some gaps in his systems and loss of money, he usually pays attention. I found that, if they are open to taking action, showing them an example and giving them a template can go a long way.

The difficulty in implementing this type of system is usually not in a lack of ability — at least not when it comes to low-tech equipment. It is sustaining the plan over the long term.

*****

What about your factory? Do they have a preventive approach, do they document a plan and a schedule, and does it provide sufficient guidance?

Or is it a simple form that is used to produce records, for auditors and customers to be satisfied when they come and pay a visit?

8 Elements of a Low-Risk Supply Chain in China

This FREE webinar will empower you to transform your supply chain in China to reduce risks. Two industry experts, Renaud Anjoran and Paul Adams from Sofeast, talk you through how to gain control over your product’s quality, on-time shipments, long-term pricing stability, and continuity of supply.

Ready to watch? Register by hitting the button below: