For purchasers who are not used to working with a QC inspection agency, it can be challenging to understand what the sampling plan really looks like:

For purchasers who are not used to working with a QC inspection agency, it can be challenging to understand what the sampling plan really looks like:

- How many pieces are checked?

- Are some tests/checks/measurements done on fewer samples? How many?

This is what I am going to explain in this article, based on a simple example.

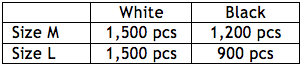

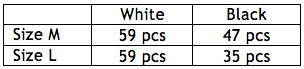

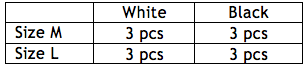

Let’s say you order 5,100 pcs of T-shirts with this breakdown:

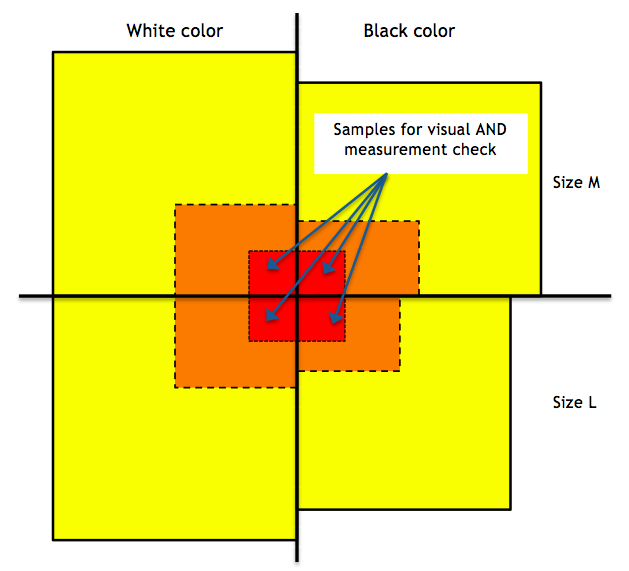

The total order quantity can be represented graphically this way (drawings are not up to scale, for better clarity):

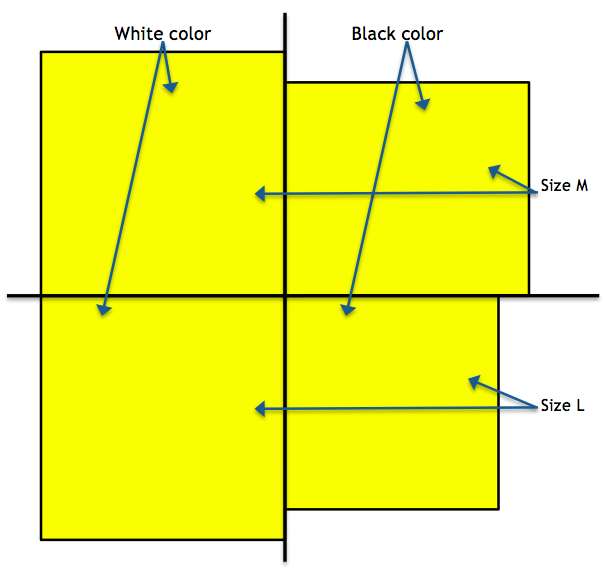

If the inspector follows the ISO 2859-1 standard in normal severity and level II, he should draw 200 pcs for visual check. (To understand how these statistics work, read this article or watch this 7 min video).

I recommend to follow the same breakdown as the total order, which gives us:

And, if we render it graphically, it looks more or less like this:

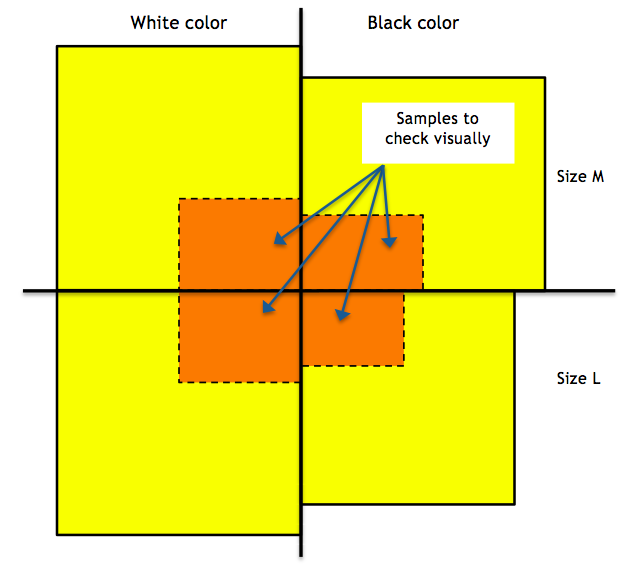

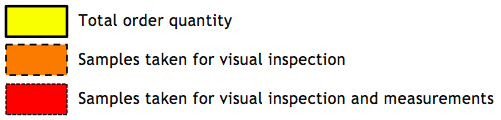

But what about the measurements? Checking a T-shirt visually is much faster than measuring it. If 200 pcs need to be measured, the inspection may well last for more than 1 day.

So the sampling plan might include a measurement check on, for example, 3 pcs in each size and each color (both a visual and a measurement check are performed on these 12 pcs).

On our graph, it looks somewhat like this:

The idea is that certain special points should not be checked on all the samples that go through a visual check. There can be several reasons for this:

- Maybe these special checkpoints take a long time. In this example I mentioned measurements of garments. But it could have been an assembly test on tables, or a full function check on an Android phone.

- Maybe these checkpoints destroy the product. If you need to fire a bullet in order to test it, you’d better not test the entire batch this way.

The problem with this approach is, can we reject the whole batch if 1 piece of T-shirt (black color, M size) is out of tolerance when measured?

My policy is to reject and to ask the client to take a decision. Some other companies prefer to follow the statistics and accept the batch if few pieces (less than the limit) are found out of tolerance. There is no right or wrong answer, as I mentioned a few years ago here.

What do you think? Is this example clear and easy to follow?