Drawing samples is a critical step during a quality inspection. Some inspectors were never trained properly to do it, and most others take shortcuts.

Drawing samples is a critical step during a quality inspection. Some inspectors were never trained properly to do it, and most others take shortcuts.

I guess poor sampling is responsible for 30-40% of the complaints that inspection firms receive from their clients (when quality problems are present but weren’t noticed).

I tried to lay out a simple procedure for drawing a set of samples that is as representative as possible, while keeping the investment in time reasonably low.

How many export cartons to select?

- At least the square root of the total number of export cartons, for first inspections

- At least 1.5 times the square root of the total number of export cartons, for re-inspections

How to select cartons?

Select cartons randomly, and covering all sizes and colors (if applicable).

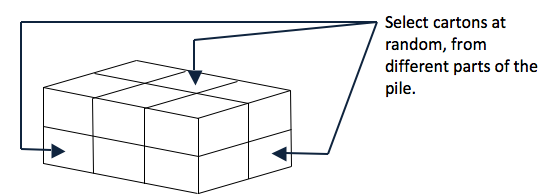

Inspector must select export cartons from different parts of the pile of cartons: from the top, from the bottom, from the sides, from the center (see below)

If some cartons are hard to reach or hidden (at the back or in the middle of the pile), inspector must select a few of them.

If the cartons are arranged in a way that makes it impossible to reach certain cartons (example: several rows and a wall behind), ask the factory to move the cartons. If they refuse, write a remark in the QC report.

Inspector must double check if the numbers of selected cartons are random enough. If not: replace repeated series numbers by other carton numbers. Example of series: 13, 15, 17, 19.

Transportation of selected cartons to the inspection area

All selected cartons must be chopped by the inspector (except if the outer carton is a gift box). Inspector must record the carton numbers in the report.

The transportation of cartons from storage location to the inspection location must be monitored closely by inspector. Remind the factory to be careful not to damage cartons.

Opening the cartons, and drawing the samples to check

Inspector must open all cartons by himself, or supervise the opening of the cartons. Do not open all cartons at the same time: open 50%, and then 50% later.

In case the inspector has to leave the inspection room temporarily (lunch), he must reseal the opened but un-inspected products.

Take the right number of samples out of the cartons, from the top, center and bottom.

Is it clear? Is anything missing?

++++++++++

Related reading: How does a random quality inspection work?