One of our developers prepared this simple AQL calculator for Sofeast.

You can use it instead of reading the AQL tables to quickly produce your sample size and permissible defect number.

Use the calculator now

(This is based on the ISO 2859-1 standard, normal severity, single sampling plans only.)

How to use the calculator to work out your AQL samples and defects

Here is an explanatory video, if you are wondering how it works (it starts with an overview of the way to read the classic tables, and then it goes on to show how this tool works):

First, for the product to be checked, select the ordered quantity (batch size) and the inspection level. This will give you the number of samples to pick for inspection.

Second, indicate the AQL limits you and your supplier have agreed on. You will know the maximum number of defective pieces that are allowed.

Basically, we are not re-calculating all the values using a binomial (not really correct) or hypergeometric (the purists would do this) law. This interface automates the reading of the tables, nothing else.

One benefit is, you will always be able to show your supplier where the numbers come from since there is nothing that the good old ‘AQL tables’ don’t show.

The AQL tables that the calculator is based on

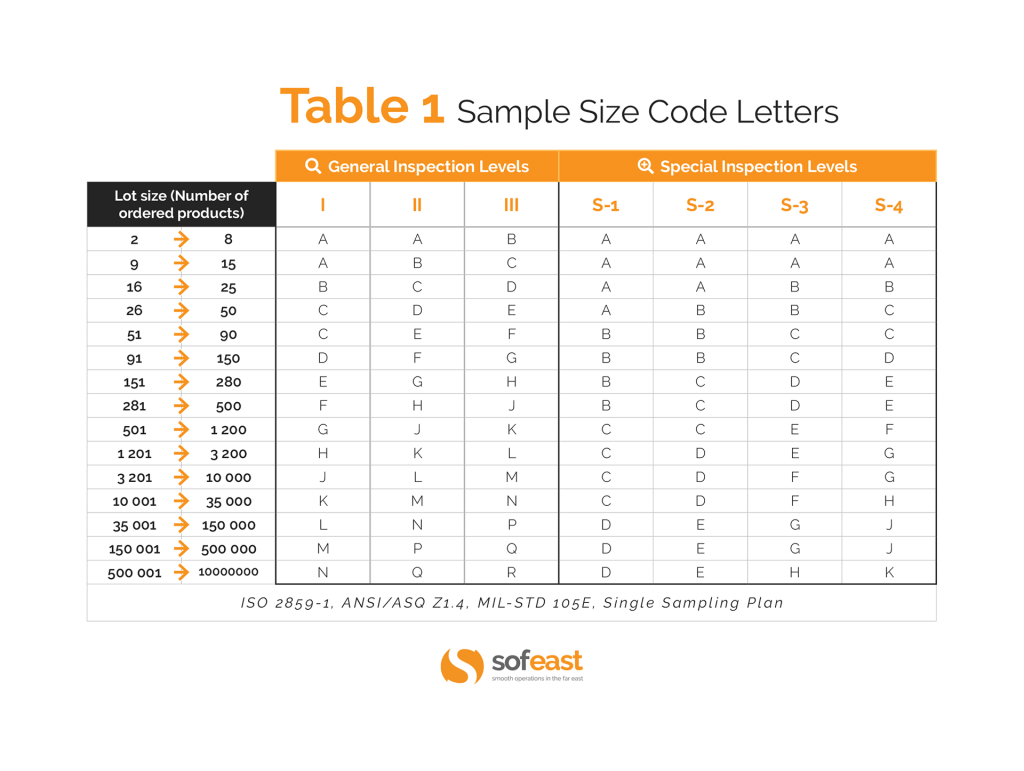

First table: sample size code letters

Here is where you will see the code letter, based on the batch size (for single sampling plans):

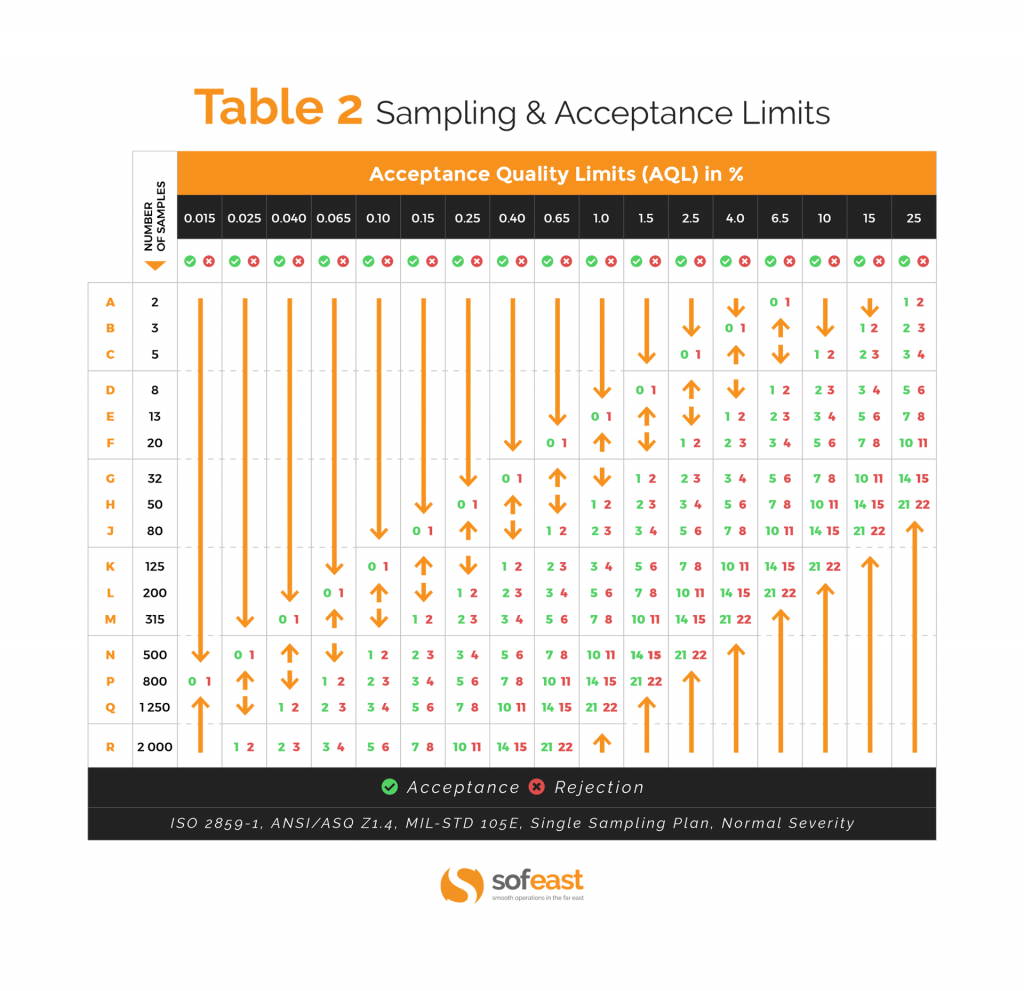

Second table: single sampling plans for level II inspection (normal severity)

And this is where you see the number of samples to pick (for normal severity and level II) and the AQL limits:

Additional reading: Read this post to learn more about reading the AQL tables.

FREQUENTLY ASKED QUESTIONS

Q: All this looks quite complicated. Why not just check 10% of the whole quantity?

A: In that case, what are the maximum numbers of defects you can accept?

Will you simply say “I don’t want more than 2% of defectives, so I reject the batch if more than 2.0% is found”? What about the normal margin for error when deriving conclusions about a whole population based on observations on a few samples? There is a high chance you reject batches that are actually acceptable.

I’d suggest you don’t get into this and don’t try and re-invent the wheel. These statistical rules were developed over 80 years ago and, for their purpose, haven’t done a bad job.

Q: Why not do the calculations directly based on the formula? For example, if I want a limit of 2% and I only have time to check 200 pieces, this could be quite useful.

A: That’s possible. However, in the vast majority of cases, Asian suppliers will look at your numbers with suspicion if they deviate from the “preferred” values shown in the classic tables. They will not compute it themselves. If you reject a batch based on rules you generated yourself, do you want to get into long discussions?

Quality Assurance Policy For Importers In China [Webinar]

What is the 80/20 rule when it comes to QC in China? The answer is building a strong quality assurance policy of your own.

In this webinar, we’re going to explore key challenges facing importers from China, and the elements that compose a really solid, effective quality assurance policy.

Improving your quality assurance will help avoid poor quality products from hurting your business. Hit the button below to register to watch the webinar!