A reader wrote to me and asked the following question about sampling plans by attributes: What is the "Confidence Level" when using the AQL Tables? How can we determine what the confidence levels are, and are there formulas we can … [Read more...]

A Simple AQL Calculator To Prepare Your Product Inspections

One of our developers prepared this simple AQL calculator for Sofeast. You can use it instead of reading the AQL tables to quickly produce your sample size and permissible defect number. … [Read more...]

The Special Inspection Levels in the AQL Tables

A few years ago I wrote about the inspection levels, but I regularly notice that some people are confused about the "special" levels (S1, S2, S3, and S4). Here is what the ISO 2859-1 standard says (emphasis is mine): The inspection … [Read more...]

What is the “AQL” (Acceptance Quality Limit) in simple terms?

What Does AQL Mean? 'AQL' stands for 'Acceptance Quality Limit', and is a method used by many businesses to check a random sample from the production batch of their products and confirm that the risk of bad quality is relatively low. In … [Read more...]

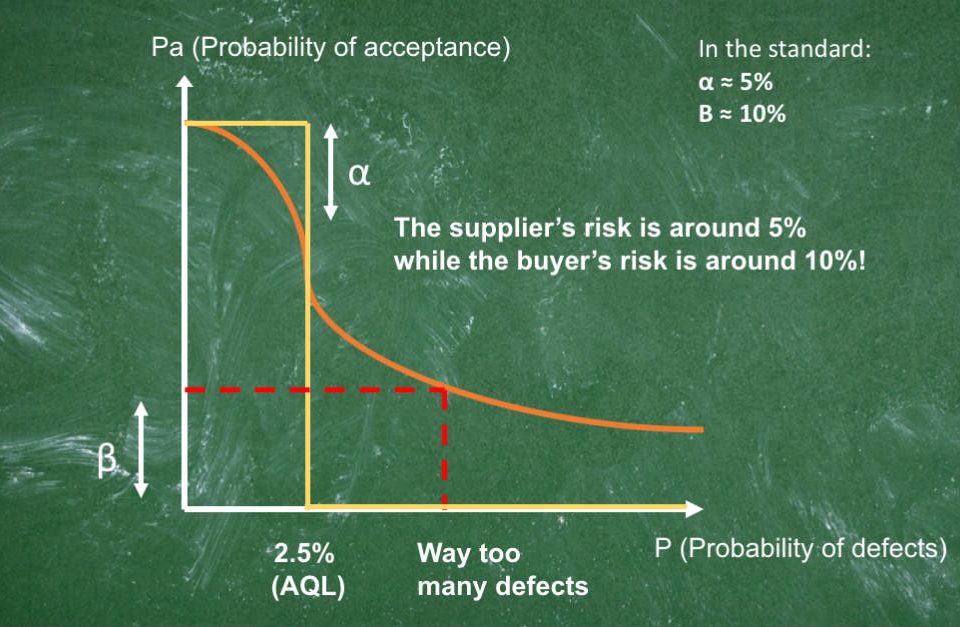

Why the AQL tables are not in favor of the buyer

This is the third and last video about the ANSI tables (also known as “AQL tables”). As I explained in the last video, these sampling schemes were designed for very stable relationships, where the manufacturer keeps making the same … [Read more...]

How to choose an AQL limit?

A few months ago, I wrote an explanation about the "AQL": what it is and how to use it. I also listed a few frequent questions, but it seems like I forgot one of them: What AQL tolerance is suitable to my products? Unfortunately, it is … [Read more...]