In this episode… Renaud Anjoran, Clive Greenwood, and Max Phythian who boast decades of experience in manufacturing around the world dive into the costs of quality, especially poor quality such as defective parts coming from … [Read more...]

What Is Good Quality Assurance For Importers Buying In China?

A client was interested in product inspections, and they asked: Do you also offer a post-inspection service, for cases where the results are not ideal? That got me thinking. The answer is simple, yes, we can keep following up, but … [Read more...]

Undetected QC Issues: 7 Common Failures of Chinese Inspectors

Quality inspectors are human like the rest of us, and while it's usually unlikely that they will let major QC issues slip through the net, it can happen. Let's examine why and how this happens, and how to mitigate or stop these … [Read more...]

A Simple AQL Calculator To Prepare Your Product Inspections

One of our developers prepared this simple AQL calculator for Sofeast. You can use it instead of reading the AQL tables to quickly produce your sample size and permissible defect number. … [Read more...]

Managing QC Inspectors, Part 8: QC vs. QA

This is the eighth part in the series about the management of QC inspectors in China. Different companies give different job descriptions to their inspectors. I don't think there are "best practices" here, but this is an important topic … [Read more...]

Managing QC Inspectors, Part 7: The Quality Manager in China

This is the seventh part in the series I am writing about the management of QC inspectors in China. Many companies in China have difficulties finding the right quality manager. In particular, it is difficult to find an individual who will … [Read more...]

Managing QC Inspectors, Part 6: Planning the Inspections

This is the sixth part in the series about the management of QC inspectors in China. In my last article on this topic, I mentioned the need to have system to manage the planning. Some companies let factories and inspectors set the … [Read more...]

Managing QC Inspectors, Part 5: Avoiding Bribery

This is the fifth part in the series about the management of QC inspectors in China. I touched on the evaluation of quality inspectors, and it naturally brings up the topic of bribery. How big of a problem is corruption of inspectors in … [Read more...]

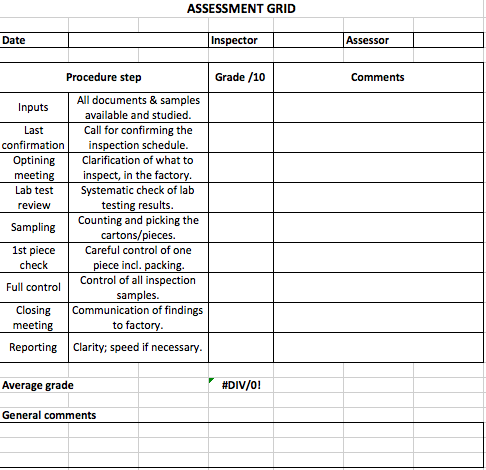

Managing QC Inspectors, Part 4: Evaluating their Performance

This is the fourth part in the series about the management of QC inspectors in China. Let's say you have hired the right profile, you have given them the right equipment and the right checklist, and you have provided them with the right … [Read more...]

Managing QC Inspectors, Part 3: Training, Coaching, and Auditing

This is the third part in the series about the management of QC inspectors in China. Let's focus on the activities of training, coaching, and auditing inspectors. A few years ago I listed 7 ways inspectors can fail to notice quality … [Read more...]

![Exploring The Cost Of Quality When Manufacturing In China [Podcast]](https://qualityinspection.org/wp-content/uploads/2021/10/ExploringTheCostOfQualityWhenManufacturingInChinaPodcast.jpeg)