This is the fourth part in the series about the management of QC inspectors in China.

This is the fourth part in the series about the management of QC inspectors in China.

Let’s say you have hired the right profile, you have given them the right equipment and the right checklist, and you have provided them with the right mix of training and coaching. You need a method to evaluate their performance in order to know who should receive a bonus and/or a raise… and who should be let go.

1. Defining expectations clearly

You can’t hire Chinese inspectors if you don’t have a company established in Mainland China and if you don’t sign a labor contract with them. But, besides these legal requirements, it is quite important to get the inspectors’ written confirmation of all important requirements.

One of these requirements is the procedure to follow for inspections. Do NOT think “it is common sense work and they know how to do it”. In China, counting on employees to decide how they will carry out their work is usually not a good idea.

For example, for a buying office, the process steps involved in an inspection might be as below:

- Inputs — All documents & samples available and studied.

- Last confirmation — Call for confirming the inspection schedule.

- Opening meeting — Clarification of what to inspect, in the factory.

- Lab test review — Systematic check of lab testing results.

- Sampling — Counting and picking the cartons/pieces.

- First piece check — Careful control of one piece incl. packing.

- Full control — Control of all inspection samples.

- Closing meeting — Communication of findings to factory.

- Reporting — Clarity; speed if necessary.

2. Reinforcing the importance of stated expectations

The evaluation process is directly linked to the inspector’s pay. It means inspectors pay a lot of attention to it. This is an excellent way of reinforcing the message that compliance to the procedure is not optional.

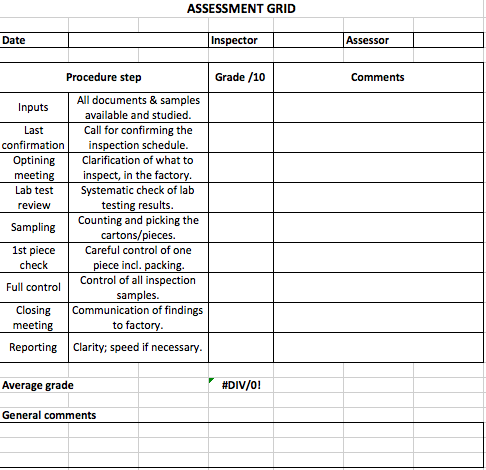

Based on the above example, the coach or auditor might use an evaluation grid such as this:

The evaluation sheets need to be reviewed during each performance review (to be performed every 3-6 months). Other inputs to the performance review can be:

- Big mistakes (e.g. complaints from customers that point to the inspector’s negligence)

- General behavior (responding to the the manager’s phone calls, being early in factories, acting clearly with independence, respect of confidentiality, etc.)

- General communication skills

3. How to motivate Chinese inspectors?

Chinese employees in general say they want a higher pay. But obviously there are many other elements at play. The most important is to avoid what usually pushes good employees to leave their employer. Here are a few examples:

- No personal growth prospects (no training, no new skills such as trouble shooting technical issues, etc.)

- Strong pressure that is felt by the employee as excessive relative to the salary, the authority, and the resources. This is often linked to unclear definition of the process to follow and the overall expectations at time of hire.

- Lack of respect from the immediate supervisor and/or manager.

- A feeling of being useless — for example shipments are always authorized because “it is really urgent”.

Most buying offices get their whole inspection team together once or twice a year. But this is not sufficient. A regional supervisor should organize small gatherings every two weeks, to ensure inspectors feel part of a team and feel a direct connection to other people in their company.

Another way of making inspectors feel valued is to have purchasers (or merchandizers) come regularly to work alongside them in factories. This is a must if you feel internal communication among your team is weak.