In this episode… Renaud Anjoran, Clive Greenwood, and Max Phythian who boast decades of experience in manufacturing around the world dive into the costs of quality, especially poor quality such as defective parts coming from … [Read more...]

How To Add Process Validation To Your QA Plan

If you (or your suppliers) suffer from inconsistent quality, in many cases there is at least one missing ingredient in the quality assurance plan. And, more often than not, process validation was skipped. … [Read more...]

What Is Good Quality Assurance For Importers Buying In China?

A client was interested in product inspections, and they asked: Do you also offer a post-inspection service, for cases where the results are not ideal? That got me thinking. The answer is simple, yes, we can keep following up, but … [Read more...]

Using Data for Quality Management: Do You Have Puzzle? Or a Mystery?

As I wrote a few weeks ago, quality control analytics can save serious costs. I listed 5 examples of such cost savings in that article. Now, the question is, what can manufacturing and purchasing managers do to utilize data for quality … [Read more...]

How Quality Planning Drives QC and Process Improvement

What does quality management consist of? Juran wrote about this first in 1986, and he suggested 3 types of activities that make up the "Juran trilogy": Planning Quality control Improvement … [Read more...]

Are Calibration Reports Always A Must? Why Auditors Should Think Before Raising Suppliers’ Costs

By Annie Chan Did you get a visit from an auditor who seemed obsessed with calibration reports? Was he/she happy to see that all tools had been calibrated based on internal reports, or (even better) on third-party lab … [Read more...]

How Much Does a Quality Inspection in China cost?

Understanding the cost of quality inspections in China I am always surprised by the expectations of some importers regarding the cost of quality inspections in a Chinese factory. Some importers get to talk about their project for some … [Read more...]

Must-know Basics of Quality Assurance in China & Vietnam for Buyers

Many new or inexperienced importers who are outsourcing their production to suppliers in China (or wider Asia such as Vietnam) for the first time go into the process almost blind. They're later hit with crippling issues that can make the … [Read more...]

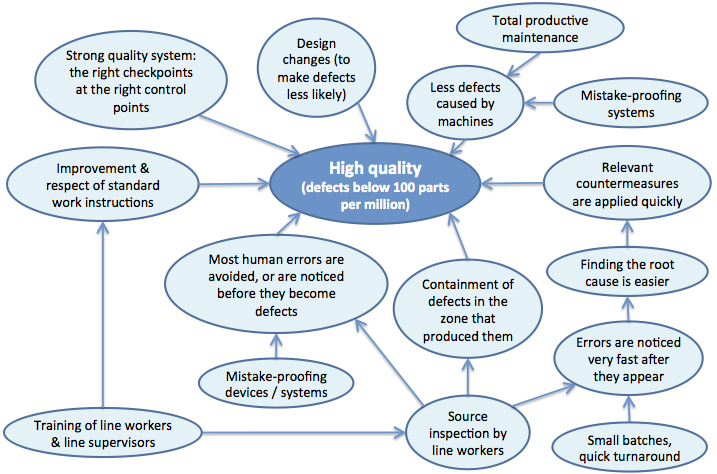

How a Chinese factory can REALLY improve its quality

Auditing a factory's quality system, and helping them patch the main holes found by the auditor, is helpful. But is it enough? I used to think so. A good quality management system is supposed to stop defects before it is too late. … [Read more...]

![Exploring The Cost Of Quality When Manufacturing In China [Podcast]](https://qualityinspection.org/wp-content/uploads/2021/10/ExploringTheCostOfQualityWhenManufacturingInChinaPodcast-960x628.jpeg)