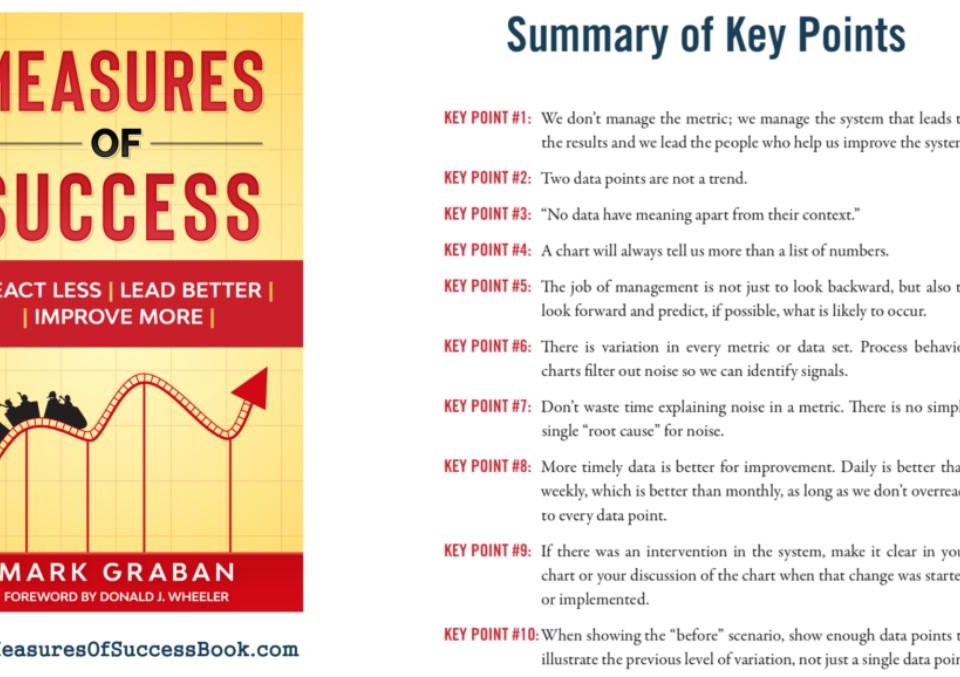

I just read the book Measures of Success by Mark Graban, and I found it does a great job of covering the basics of how managers should work with data. His whole approach is largely based on concepts from Don Wheeler's books. If you are … [Read more...]

Does ISO 9001 Actually Prevent Process Improvements?

As I wrote before, I believe that a good implementation of ISO 9001 does help a manufacturer quite a bit, while a bad one will only create issues. And the reason is simple. ISO 9001 allows an organization to set any system it wants, as … [Read more...]

How To Keep A Clean Factory And Stop Dust On A Budget

In many industries, one of the most common reasons for defective goods is dust contamination, and they have adopted different cleanliness standards (see the Wikipedia page on cleanrooms and factory cleanliness). If you have visited … [Read more...]

A Key China Sourcing Criterion: Can Your Factory Improve?

If you are only going to place 2 or 3 orders with a supplier, the key sourcing criteria will probably be quality, price, past production of similar products, and understanding of compliance requirements. However, if you are looking for a … [Read more...]

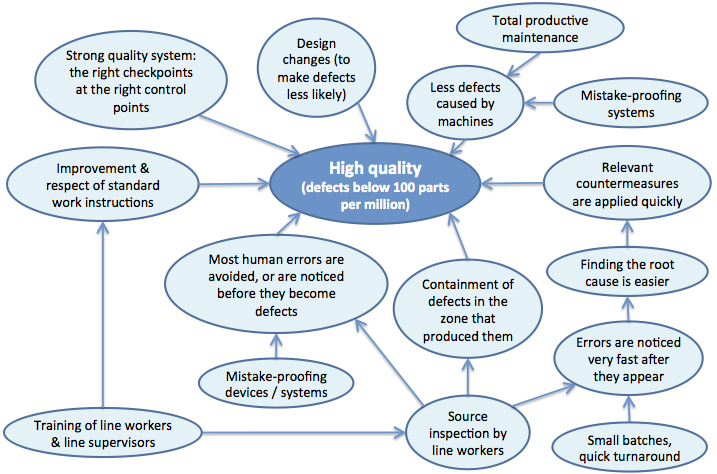

How a Chinese factory can REALLY improve its quality

Auditing a factory's quality system, and helping them patch the main holes found by the auditor, is helpful. But is it enough? I used to think so. A good quality management system is supposed to stop defects before it is too late. … [Read more...]