If you source and buy consumer goods from several suppliers in China, your experience probably looks like this:

- Some suppliers are good, some are not so good and not improving

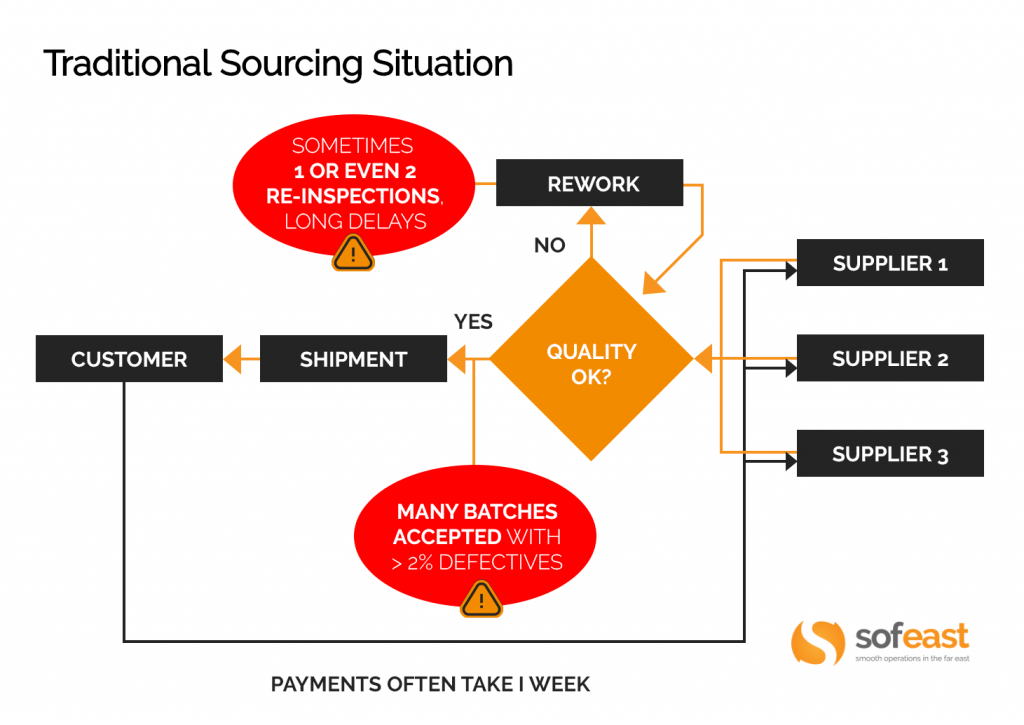

- When there is a quality issue, it is much better to detect it while the goods are still at the factory… and yet, sometimes, that factory plays the “do nothing and wait” game — it means they do a very light sorting job and tell you “all is good now”, simply because they don’t want to do rework and discard some pieces (for which they don’t get paid).

- A certain proportion of batches get accepted and shipped, even though there are 2% or even 5% of defective goods inside.

- Everything takes time. Even T/T payments take 1 week.

Is there a better, more optimized sourcing setup for importers from China?

A ‘normal’ sourcing setup in China

This “normal” situation can be represented this way:

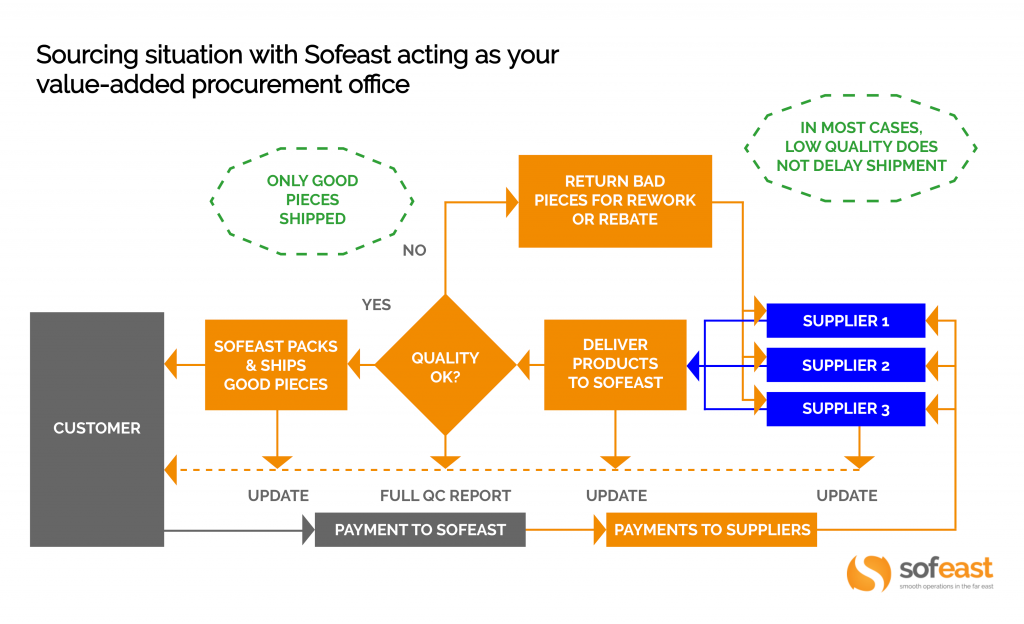

An optimized sourcing setup in China

But imagine you had your own structure and your own people on the ground, next to the factories in China. What would an optimized setup like this allow you to do?

- The manufacturers located in one area would deliver their products to one central facility.

- Payment terms would be more flexible for 2 reasons: (1) payments are local and are cheap and fast, (2) suppliers can sue the buyer in China, and can often accept to be paid 100% end of the month.

- A quality inspection would take place there, without any interference from supplier’s personnel and without having to travel all the way to the different factories

- Bad batches would be put aside for the supplier to re-work (either in their factory, or by sending a team to that central facility).

- If, say, 30% of the goods are defective, a 100% check can be done, 70% can be shipped right away, and the remaining 30% of defective products can simply be set aside (no payment to suppliers for those).

That’s what we call a value-added procurement office offering (this is a link to our commercial website). And we illustrate it this way:

We already work this way for several clients, but we only thought of drawing it after we struggled to explain it to a client a few months ago. There can be quite a few benefits at the same time. When it makes sense, it makes a big difference for the customer.

I know that some large companies (e.g. C&A for apparel, some Japanese companies for hard goods…) have done this for a long time, and there is nothing very innovative. But SMEs seldom think of such a setup.

Have you worked this way before? How was your experience? Please share with us, and I’ll make sure to comment back.

8 Elements of a Low-Risk Supply Chain in China

This FREE webinar will empower you to transform your supply chain in China to reduce risks. Two industry experts, Renaud Anjoran and Paul Adams from Sofeast, talk you through how to gain control over your product’s quality, on-time shipments, long-term pricing stability, and continuity of supply.

Ready to watch? Register by hitting the button below: