More and more Chinese suppliers put their customers directly in contact with a quality manager, an assistant quality manager, or something of the sort. However, most of the time, you are not communicating with whom you think…

It usually takes one of the two forms I describe below.

Situation 1: the final QC supervisor

In many factories, we see more than 20% of the staff works on inspection and rework activities. They wait until products are finished, sort out the bad stuff, re-process it, then check it again…

After that, the customer-nominated inspectors come in, check quality, reject some batches, and it all starts over.

The main representatives of customers are the inspectors they send in factories!!

Remember, Chinese students all study in order to pass the exam. A very cynical attitude prevails here. Same thing for quality control — ‘if it passes the buyer’s inspection, we pass’.

Therefore, the quality department is often seen as part of the sales department (let’s keep the current customers happy) or part of the shipping department (let’s make sure the customer’s inspectors don’t stop shipment and we get paid soon).

It is NOT what you might expect — the department that helps production get better. (This might include mistake-proofing processes, developing work instructions, training the staff, and so on.)

So, if you are in contact with someone from the quality department and that person only talks about inspection, you are talking to a sales rep.

Situation 2: the “inconvenient paperwork” handler

There is a serious quality issue. A customer wants to know exactly what made it possible, and what changes the factory will implement to avoid recurrence of that specific issue.

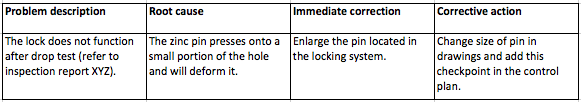

A very common troubleshooting form is the corrective action plan. Here is a simplified example:

The two areas that 99% of Chinese manufacturers NEVER do right:

- Root cause analysis — they often remain at a superficial level.

- Followup — finding what to do is great, but will it really be done consistently?

Now let’s break the problem down and see why the customer is so often disappointed by Chinese manufacturers:

- Will the production department explain what happened? Yes, and hopefully it is the truth. Will they communicate in English? Probably not. In English and in written form? No! They have to make their numbers today. In 95% of cases, their only incentives are linked to the number of pieces made — they might not even know the customer’s name. So, at best, you are relying on a salesperson’s translation of a technical issue she might not understand.

- Will the production department, the engineering department, a sub-supplier, or whatever party is most directly concerned, work on finding the root cause(s) that need to be addressed to prevent recurrence? Based my own 11-year experience in this field, very seldom.

- Will the party most directly concerned make the required changes? They might show some goodwill and do something. But, since they haven’t done the hard work of uncovering the root cause(s), it will often be useless.

In this context, manufacturers that work for large customers and MUST report on what happened and how it is being fixed have to find solutions. One common fix is to hire some people in the quality department who will fill out the paperwork the customer wants (typically a corrective action plan, a FMEA, a control plan, etc.)

Will production even read those documents? Maybe yes… and usually not. Take them with a grain of salt. They are probably written to make you feel good!

—

What do you think? Is this conform to your experiences?

Working as a merchandiser for around 11 years, I faced a lot of similar quality incidents. I want to say, what you observed and concluded is totally correct, at least correct with me.

Seldom of the manufacturers here in our country really care about the quality issue. What they care is to pass the inspection.

“Chinese students all study in order to pass the exam.” This is a brilliant conclusion.

Thanks Richard 🙂

These observations are consistent with my experience as well. A few things I have found helpful in pressing for improvement:

1) I do regular ( 2- 4 per year) process audits at my suppliers, and one thing I always check on is the implementation of corrective actions. In particular, I check to see that the C/A’s have been implemented systemically on similar jobs, After some years of training the better suppliers understand this. Be ready for denial by the factory people, too… In one situation, I had a stamped steel part that was out of spec in one area. My email alerts were met with reports that nothing was wrong. When I came in person 8 weeks later, I found that the stamping die involved was still broken, even though at least 2 more batches of new production had been run! (They were all nonconforming, of course!)

2) With regard to the documentation questions, I ask for the original documents in Chinese, and tell the sales rep/interpreter to provide the originals; I’ll have them translate just a few sections. (No, I don’t read Chinese!) My long, sad experience was that if I received nice English language documents, at best they were true when the issue was handled (sometimes not even then); but over time the problems would recur, because the factory personnel couldn’t read the English stuff. If it was written in Chinese there was a fighting chance that the material would remain accessible to the factory technical people.

3) And, be patient. I’ve been doing this since 1987. US auto parts factories were just as bad at corrective action in the ’80s; in the ’90s and ’00’s, the auto industry people finally started to get serious about C/A’s. But, truth is that this stuff is hard to do well. And, while it’s easy to claim that better quality saves money, often the ROI on after the fact C/A’s isn’t very good.

Thanks Brad. Interesting.

“I ask for the original documents in Chinese” –> I love that.

“often the ROI on after the fact C/A’s isn’t very good” –> yes I guess it is sometimes pretty hard to justify with a ROI calculation — except if you give them massive penalties.

Agree. Even in factories that have the 6-sigma posters plastered all over the shop-floor we still see this, so don’t be fooled by appearances.

Yes, good point. A quick look into their beautiful corrective action plans is usually enough to detect by savvy production/quality people.