What does it take to go from concept to market for a typical electro-mechanical consumer product in terms of milestones and costs? Also, what pitfalls should you be looking out for that could slow down your product launch and increase its costs?

The NPI process you follow to get to market involves many steps and costs, so this discussion gives an overview of the journey.

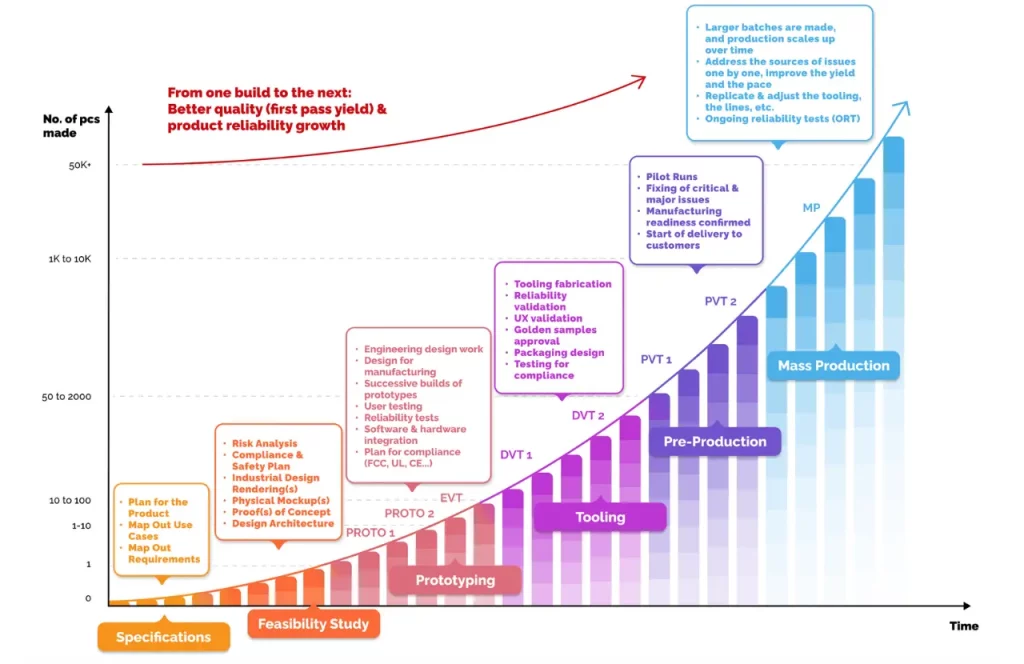

We broke down the process here to illustrate the phases and tasks involved so you can see what lies ahead:

The different phases, along with their approximate costs for a typical consumer electronic product as an example, are discussed in the episode, so hit play to start exploring.

Here’s a summary of some of the main points…

Typical cost drivers.

Rather than asking about costs, a better question would be: “What are the cost drivers.” So, we’ll look at those.

Do you want to develop the product from scratch and have the budget?

We can usually give a rough estimate on costs to get to a final prototype and industrialize it, say $50,000, and then to get it to mass production including reliability and compliance testing, and finally to start production. If you don’t have the budget for this, maybe you start small by private-labelling some existing products and growing the business, and later launching your new product when you have more funding. (04:29)

Getting to a mature product concept (requirements, design, renderings).

To be mature, your product concept needs to have solid requirements and specifications, such as size and weight, Bluetooth performance, and waterproofing. You also have industrial design and renderings of the product. This answers a lot of questions about the product and allows the cost to be estimated more easily. You should also do market research to estimate what your product should sell for and then work on estimating the full landed cost plus some profit margin. (09:15)

Going through prototyping.

You will build different versions of prototypes going from look-alike to fully functional engineering prototypes. This phase could cost between ten to a hundred thousand dollars for a product of low-to-medium complexity, it really depends on the product complexity and how much engineering work is required on the prototypes. Products with firmware will also cost more due to programming costs on top of product engineering. The danger here is devising a product that is too complex for a V1.0 and will require large resources to go through the prototyping stage. Reliability testing then needs to be done on the final prototypes to ensure durability in the field, and there may be design or part changes based on the failures. Doing pre-testing for compliance and safety is also important, especially as this is connected to being able to sell the product in certain markets such as the EU or USA. When there are no further changes to prototypes due to testing results, the design and CMF can be frozen. (15:18)

Fabricating tooling.

Many consumer products will require injection molded plastic parts of some description. Fabricating tooling is costly, so you need a frozen design first as any changes to tooling are costly and time-consuming as tooling can easily cost $50 to 100,000. That’s why the testing and validation of prototypes is so important first. Tooling cost s dependent on product complexity, something simple like a mug might be 10k, whereas an extremely complex product like the Juicero could be hundreds of thousands due to its many parts (this is one reason why this overly expensive product failed). (22:54)

Pilot run and compliance and safety certifications.

Now that some early products are coming off of tooling, they need to be sent for compliance and safety testing. For example, RF testing for electronic/electrical products, CE marking and its associated tests, chemical testing, etc. This can range between a few to, say, twenty or thirty thousand dollars for more consumer products, but is essential for the same of new products. Reliability testing on the production standard products may occur now, as well, and this could be a few thousand dollars. The cost do the initial production setup and run the pilot runs in the first place also needs to be taken into account, as a contract manufacturer will charge for this setup. (26:01)

Production and logistics.

Batches of materials and components need to be ordered and you may need to find the cash to pay for an MOQ from suppliers. Payments to the manufacturer are usually paid 30/70, with the initial deposit sent before work starts and then the balance paid when products are completed and ready to ship. Logistics costs will also need to be paid and this will increase the faster you need products; so air freight will be more costly than sea freight. There will also be important costs, tariffs, logistics to the warehouse in your country, and fulfillment costs to consider. (27:46)

Common mistakes made during product development.

While knowing the cost drivers is good and will help you to estimate costs, some common mistakes will no doubt increase costs and delays.

- Going in the wrong direction with design architecture. Let’s say the team struggles to make a design work with various prototype iterations for 6 months and they have to go back to square one because the chipset is wrong, for example; that’s costly. More initial research and checking could avoid this.

- Designing a product without taking into account the realities of manufacturing and assembly. We’ve all seen Kickstarter projects that failed after promising amazing products. Oftentimes it’s because they didn’t get user feedback, feedback from their suppliers, or do DFM or DFA analyses initially. If they did, they wouldn’t have gone down the wrong path and could have made design changes before time and money were wasted.

- Being too secretive about designs. Some companies fear being copied so much that they won’t tell any third parties about the product, meanwhile spending a lot of time and huge sums of money developing a product that it turns out no one wants or needs. Getting feedback is critical, and there are protections like manufacturing contracts and NDAs that can protect IP.

- Working with the wrong contract manufacturer or suppliers. Do your due diligence to ensure that you source a supplier who has the capabilities to reach your needs. (30:43)