Auditing a factory’s quality system, and helping them patch the main holes found by the auditor, is helpful. But is it enough?

Auditing a factory’s quality system, and helping them patch the main holes found by the auditor, is helpful. But is it enough?

I used to think so. A good quality management system is supposed to stop defects before it is too late. However, I have seen too many Chinese manufacturers get very high scores on a quality audit, and then try to ship batches containing 5-20% of defective goods.

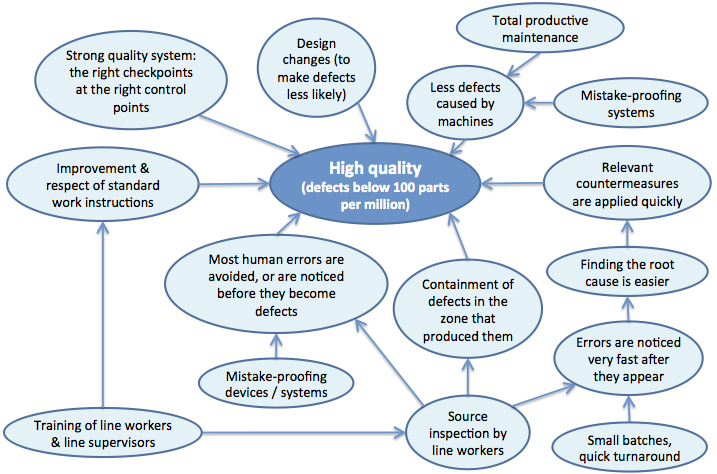

Setting up control points relevant to each production step does help, but improving quality takes much more:

- The factory’s management needs to give quality the priority over short-term costing & timing issues.

- Other tools need to be in place if the defect rate is to decrease from ~5% to ~0.5% or lower.

What other tools? What they call jidoka at Toyota. It is actually a whole system:

How to reduce the occurrence of defects and reduce costs

- Standard work instructions should be well adapted to each operation and should be carefully respected by line workers.

- Mistake-proofing devices should be put in place. You can see examples of “poka-yoke” at the bottom of this article.

- In an ideal one-piece-flow production system, it is easy to find the cause of a defect that was just noticed and to set up countermeasures. On the contrary, after a large batch has been through a few process steps and defects are found (let’s say two weeks after their creation), this is a much more difficult exercise.

- Large and high-speed machines should be avoided whenever possible. This way, there is no need to supervise them constantly (no risk of spitting 300 defective parts out in 1 minute).

- Sometimes, changes in the product’s design can help reduce the number of defects considerably.

Note: contrary to what most people believe, the above elements do not increase costs. For those sceptics amongst you, please see how lean principles drive costs down.

How to catch and contain defects

These elements, in themselves, do not reduce the proportion of defects. And they add to costs.

- Operators should look for errors from the previous process, or from their own work, and then immediately react to defects.

- The above step should be part of a coherent and relevant quality system. Anything that cannot be corrected immediately (by the operator that found it) should be recorded in a report/registry.

To sum up, a strong quality system does not reduce the number of defects in production. It only helps catch them before shipment to the customer.

And, hopefully, the manufacturer does something about it (and does not short-circuit the system by shipping the goods anyway). In China, that’s one big assumption!

In theory, the quality system reduces the occurrence of defects

I am well aware that, according to the ISO9001 standard, the manufacturer is supposed to:

- Review designs and validate (through testing) the fact that they are fit for production;

- Ensure that standard work instructions are up-to-date, relevant to the operation it corresponds to and are followed by workers;

- Identify and segregate non-conforming products;

- Establish and implement corrective action and preventive action plans.

However, this is pure theory.

In reality, I guess less than 0.1% of Chinese manufacturers truly follow these steps.

Others (maybe 10%) prepare papers to pretend they do it. Or they pay “consultants” that help them pass quality audits. In any case, they have no intent to “waste time” with these procedures.

Do you see the same thing out there? Let me know by leaving a comment.

Sofeast: Quality Assurance In China Or Vietnam For Beginners [eBook]

This free eBook shows importers who are new to outsourcing production to China or Vietnam the five key foundations of a proven Quality Assurance strategy, and also shows you some common traps that importers fall into and how to avoid or overcome them in order to get the best possible production results.

Ready to get your copy? Hit the button below:

Very Interested …..See if I can applied such method in my factory