Some buyers realize that they need to keep a close eye on production is important, and that catching problems earlier is far cheaper than later. This is an approach I strongly encourage.

Some buyers realize that they need to keep a close eye on production is important, and that catching problems earlier is far cheaper than later. This is an approach I strongly encourage.

There are two ways of checking production closely:

- Taking several snapshots along the production cycle, by performing 1-day inspections,

- Looking at the movie as it unfolds, by stationing 1 technician in the factory for a certain period.

Let’s look at these two solutions one by one.

1. Inspecting During Production

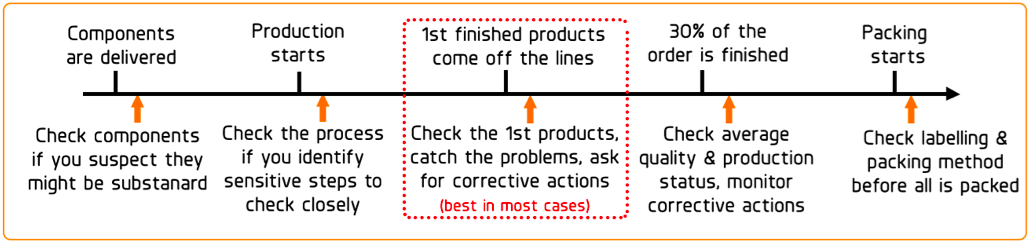

The idea is to send a technician or engineer to a factory, generally for one day each time. When to do it? The key is to identify the main risks in production. Here is a generic representation that applies to many product lines:

(Note that the production of sub-suppliers can also be inspected. It doesn’t necessarily all take place in the same facility.)

Three things can be confirmed:

- It is basically an inspection of the components, the process, and/or the product. They are compared to the buyer’s specifications and/or to best practices (hopefully the inspector is an experienced engineer and performs a process audit).

- The production status and allocated capacity can be checked and compared to the supplier’s promises.

- The place of production can be confirmed, as well as what processes are done in-house vs. at a subcontractor’s.

If serious issues are found, the following sequence can be followed:

- The inspector issues a CAR (Corrective Action Request),

- The quality manager can push the supplier to prepare a CAP (Corrective Action Plan) and give comments about it,

- The inspector checks if the CAP has been applied effectively.

(Note that most Chinese inspectors are capable of issuing a CAR and then checking if a CAP is effective, but fewer of them can confirm the CAP proposed by the supplier — in most cases this is done by a quality engineer or a quality manager.)

For more information about inspection during production, read this article.

2. Monitoring Production

Instead of sending an inspector at several times during production, for large or complex projects it makes more sense to station one technician/engineer in the “main factory”. He will do everything that an inspector does (see part 1), while keeping an eye on what happens every day.

Typically he also goes to the main subcontractors to check production status and quality. But sometimes the supplier refuses to disclose this information. The business environment in countries like China is not very transparent…

Since this stationed technician can give a “movie” rather than a few “photos” about the situation, he can set up a Gantt chart that shows, for each production step, expected and actual dates. It looks somewhat like this:

Another advantage is that corrections and corrective actions can be monitored (and reported) in real time. And, if the relationship is not too conflictual, the technician generally learns a lot about the supply chain and the main challenges of each party — sharing this information with the buyer is often priceless.

—

Have I forgotten something important?