By Fabien Gaussorgues

We have worked with multiple jewelry manufacturers in Europe, the US, and Australia. In this time, I realized that their knowledge is often far below what one would expect from industry experts which leads to many failures like overpricing, and gold plating problems such as plating peeling, wearing out, green effect, rust, and more. Why is this happening?

Gold plating is a challenging and complex process, so it’s important for suppliers to be aware of the process used to create their jewelry and how to check its quality so you’re not leaving it up to suppliers to make all decisions.

This blog post has 3 sections where you’ll start with how gold plating is done, understand why the industry and supplier habits cause issues, and finish with the quality checks that you should be performing (hit the links to skip to that section):

- The gold plating process: Electroplating and PVD coating

- Gold plated jewelry quality, problems with the industry that lead to problems & challenges suppliers face

- How to check gold plated jewelry quality

First, let’s examine the processes used by jewelry suppliers to create gold plated items.

Many of the relatively inexpensive items of jewellery are made of brass and plated with yellow or white gold. Let’s explore the processes used in gold plating, the causes of problems, and look at some examples that lead to poor quality jewelry.

1. The 2 gold plating processes: Electroplating & PVD coating

There are 2 main processes used for jewelry gold plating, electroplating and vacuum plating (PVD or Physical Vapor Deposition).

Gold plated pieces made with each method are generally a substrate metal like brass, 1 or 2 under layers, and then a thinner gold layer on top. However, the methods differ in how they produce the gold layer and the pros and cons of the finished pieces.

Gold electroplating

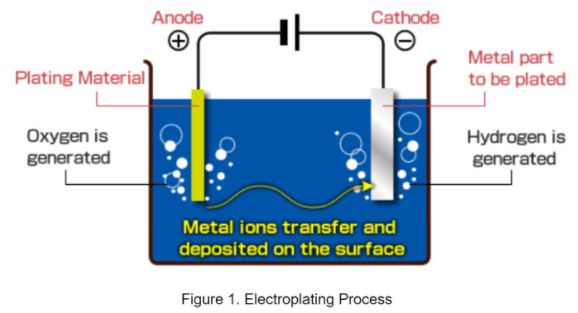

Electroplating, in simple terms, is like adding a layer of gold paint to an item of jewelry. The process works by depositing a thin layer of gold onto the base metal of the piece of jewelry ‘electrolytically.’

A plating bath full of an electrolyte solution is used and this solution (often types of cyanide) dissolves the desired positively charged plating metal which is held by the solution as positively charged ions. The base metal is also held in the solution and when an electrical current is passed through the bath the positively charged plating material ions (in this case gold) are attached to the negatively charged base metal. In this way, electroplating is achieved.

Electroplating has been around for some time, and can be used for smaller numbers of items; for instance, replating a family heirloom.

Image courtesy of https://www.iriden.jp/en/basic

Gold PVD coating

First developed by NASA to produce parts used in spacecraft, it is now popular with mass jewelry manufacturers as it provides a more durable finish and more color options than traditional electroplating. Unlike electroplating, this method molecularly bonds the gold to the base metal so it’s a stronger bond.

Instead of using an electrically charged liquid bath to transfer one metal to another, the PVD process takes place in a vacuum chamber where the plating material is electronically charged and vaporised (plasma), the molecules of which will bond with the base metal (these would be the unplated jewelry pieces) which are in racks along with it.

Image courtesy of https://dg-huicheng.en.made-in-china.com/product/dSaQnXsPCcWz/China-PVD-Coating-Machine-PVD-Coating-Equipment-PVD-Coating-System-HCVAC-.html

This process uses both real 18k gold and ‘fake gold,’ too (Zirconium Nitride – ZrCN). Even with the fake material, it can produce amazingly bright and realistic gold finishes and colors that can’t be told apart from genuine gold (in fact, some say it has an even more vivid color than genuine gold itself). Where Zirconium Nitride is used, the gold color can be varied by increasing or decreasing the amount of carbon and nitrogen used to create the ZrCN.

It is a more expensive process than electroplating and so is usually used in mass production of jewelry, tools, and other items where the scale of production reduces costs.

Features of gold plated jewelry

Let’s explore some of the key points that importers of gold plated jewelry need to understand:

The Underlayer

The purpose of this layer is to provide a better base for the gold layer, avoid gold migration to the substrate (jewelry base material) and generally has a similar color as the gold layer so a scratched or worn out gold layer is not too obvious. This layer exists in both electroplating and PVD but has a different composition.

Gold layer

Generally, the gold used is 14k, 18k, or 24k depending on quality and color. The more gold, the less resistant (easy to wear out), because gold is a very soft metal. It’s possible to use alloys instead to compensate partially for gold’s lack of durability and a varnish coating can also be added for protection that lasts a limited amount of time.

Plating thickness

Gold plating thickness ranges between around 0.05um to 3um, and higher quality jewellery tends to have a plating thickness of around 1um to 2um, but because PVD is harder the thickness is generally less than 1um for the same quality of plating.

The above parameters vary between plating companies and are based on their experience and their customers. It happens to be hard (and costly) to request an exact definition from a supplier before products are made because the parameters would be product-specific.

Costs of gold plating

Importers should be aware that quality gold plating is an expensive process. It is not uncommon for the plating cost to make up more than 50% of the jewellery’s total cost!

Secondly, now that we know how gold plating is achieved, why can poor quality and gold plating problems occur?

What physical factors affect gold plated jewellery quality?

- Thickness of the gold-plated layer as it relates to durability, discoloring, and the overall average gold thickness in the recessed areas of the jewelry.

- Hardness of the gold plated layer as it relates to scratching, incidental abrasion and resistance to chipping.

- Adhesion of the gold plated layer to the surface of the jewelry.

- Underplating of the gold-plated layer with copper and nickel to improve tarnish resistance.

- Porosity and its elimination within the gold plated layer as it relates to resistance to oxidation and diffusion.

- Color and tint of the gold-plated finish relative to aesthetics and the original manufacturers specifications.

- Surface finish as it relates to cleaning and repolishing prior to the final electroplating process

Capable suppliers need to juggle all of the above factors in order to deliver great quality gold plated jewelry, but there are problems that keep cropping up in the industry that prevent them from delivering excellent quality.

So what is happening in this industry? Are suppliers cheating buyers, or are they simply careless?

2. The problems with the jewelry industry that lead to poor quality

Poor gold plating can lead to fading color, or, worse, to a greenish effect on the user’s skin. Everybody recognizes it as poor quality.

The answer for the jewelry industry is the same as that for most other industries in China. It can be summed up as below:

- Profit maximization with a “calculated risk” approach — what others have called ‘quality fade‘;

- Reliance on so-called experience — not on facts and objective experiments;

- Buyers who don’t define their quality expectations clearly enough.

Here are a few examples of how poor quality gold plated jewelry makes it to customers

1. Profit maximization with a “calculated risk” approach

This is not specific to China, obviously. But things are a bit more complicated for buyers in China.

Suppliers consider that, once the goods are shipped, they are approved, paid, and the transaction is fully completed. There are a few reasons for that:

- High logistical costs;

- The fact that the process to return jewels is a nightmare;

- Customs clearance (cost and time) at both the supplier and the buyer sides.

What does it mean?

Manufacturers, based on their experience, try to ship products that are as cheap to produce as possible, and yet are likely to be accepted by the buyer.

For example, if a buyer is asking for 1um gold plating, the jewels might only have a gold layer of 0.5um.

Is that cheating? Yes from Western standards. “Only if it is found and is obvious” is the Chinese response. The factory knows they can argue that the thickness of the plating is hard to control, and they can often get away with it.

2. Reliance on so-called experience — not on facts and objective experiments

This is a surprising finding for most buyers. Chinese factories in general barely have an R&D team and process engineers. Their expertise is based entirely on their intuition (which they call their “experience”), and unfortunately, it can’t be fully trusted.

Side note: as Daniel Kahneman explains, professionals should only trust their intuition when they learned a skill under two conditions:

- The environment is stable over time (but is this the case? Plating factories seldom control temperature and humidity!)

- They get regular feedback from the environment (do their buyers give them quick and clear feedback? Usually not true.)

When buyers bring a new case to deal with, the supplier tries to remember similar cases. This might work fine in a factory that has been in business for many years, has kept a stable staff, and has good problem-solving abilities. It won’t work in a small workshop that was started recently.

A typical example is the ‘green effect’. It depends on weather conditions, seashore exposure, and even on the skin type (skin color having an impact on the corrosion of plating). Most factories try jewels on their staff (Chinese skin) and have no idea what will happen in other environments.

Add to that the lack of process controls, and there is batch-to-batch variation that the factory managers don’t understand and can’t avoid. We wrote about this before.

3. Buyers who don’t define their quality expectations clearly enough

Disappointed buyers often write “this is not good quality” and have nothing tangible behind that statement.

In some cases, the buyer asked for the plating to last for at least 6 months or 1 year. That’s better than nothing. But some factories see this requirement, confirm the need for 1um (or sometimes for 0.5um) gold plating, offer a competitive price, and are likely to get the customer’s business.

For a case of greenish effect on the skin, I called and discussed with tens of Chinese factories. The result was surprising. A few (yes only a few) provided real expert feedback. Most of them provided different requirements (some of them scientifically ridiculous) and said: “do not worry, we will provide great quality if your client buys from us”.

Plating, be it on jewels or other products, is an expertise area that most factories haven’t mastered. If plating is critical on your product, you might have to acquire the knowledge to guide (or force) your suppliers to be compliant with clear quality standards.

It means, as a minimum, to set up plating specifications and to have them inspected before shipment.

Common gold plating problems suppliers face

The jewelry suppliers need to overcome these challenges in order to provide the best quality plated items:

- Maintaining even plating

on the entire piece regardless of whether using electroplating or vacuum plating. - Ensuring plating consistency

Plating performance is generally +/-20%, meaning that 1.2um or 0.8um of metal thickness is actually a huge difference in quality. - Controlling color

The gold color of the jewellery can be adjusted by mixing gold with other alloys like Cu, Ti, Ar. But it’s important to note that not all colors are possible. They also need to avoid the formation of gold/other metal intermetallic compounds where the base metal leaches into the gold plating and starts to discolor it (using the right underlayer may help this). - Reducing skin allergy risk

While underlayers help to maintain jewellery color, it’s important to choose the right metal. Using nickel as an underlayer, for example, is not a good choice since it may create issues with nickel allergies. Palladium can sometimes be used as it is hypoallergenic. - Maintaining a reasonable cost

The thicker the gold plate, the longer the piece will resist wear, tarnishing, and maintain a bright color. However, this will incur additional costs and may not even be provided by some suppliers. - Reducing unexpected and poor quality plating results

These poor plating results can occur due to process or equipment issues:

– If the plating solution has been used many times, the simple answer may be that all the metal in the solution has been depleted from it.

– If you go from one brand of electroplating machine to another with a plating solution, the voltage and timing will probably be different, so the same time and voltage may not work.

– If you’ve been using older equipment with inconsistent or poor results, typical reasons are:

– The power supply is old or ageing.

– An old analog rectifier may no longer be accurate. Just because you’ve dialed it in at three volts doesn’t mean it’s outputting three volts.

– The equipment rectifier may be malfunctioning.

– The anode could be dirty or worn and not be conducting.

Thirdly, it’s now time to check jewelry quality. Hopefully, your suppliers are handling the various challenges we’ve explored earlier, but checking quality is still important for maintaining control over your supply chain.

3. How to check gold plating quality?

There are two regularly used methods for checking for gold plating problems on jewelry samples taken randomly out of production:

1. X-ray test

Fast, cheap and not very accurate. Can measure all the layers.

The X-ray will be able to show the layers and therefore you can assess the thickness of the gold plate on the item. It may look something like this:

The location of the test can also impact the result. Typically a front plane surface of the jewel would be thicker than a corner or hidden location.

2. Microscope test

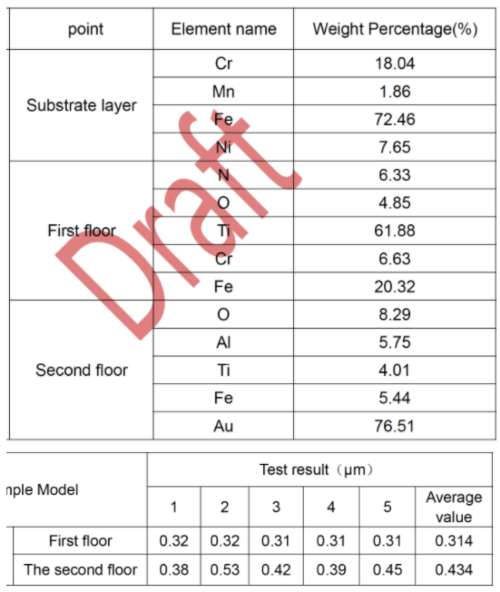

Cut and check the thickness with a microscope, and check composition too — to be done in the testing lab. Relatively expensive and accurate.

Gold plated jewelry can be examined using a microscope and a report made that outlines the plating thickness and amounts of gold (and other metals used). This can help importers to assess potential suppliers or understand if current suppliers are following their requirements.

Example of a report of 18k gold plating onto a stainless substrate

In the above report, we can see the composition of each plating layer. Au being gold, the last layer has 76.51% gold and is mixed with Iron (Fe), Titanium (Ti), Aluminum (Al) and Oxygen (O). However, oxygen is likely the coating surface which is hard to see on the microscope as transparent.

This helps importers to keep track of if suppliers are reaching gold plating requirements on a microscopic level.

Conclusion

Importers of gold plated jewelry now understand the features of the electroplating and PVD coating processes that suppliers commonly use, how suppliers in the jewelry industry (certainly in China or SE Asia at least) have certain endemic habits that can lead to quality issues and the 2 key quality checks that should be performed to assure they keep their side of the bargain.

By knowing the challenges that your supplier faces when producing your jewellery, it’s possible to anticipate and mitigate gold plating problems before they occur.

*****

What problems are you seeing with your gold plated jewelry? Do you have any experiences to share? Let us know by leaving a comment, or get in touch with us if you need assistance.

I disagree with this premise. If you go with the more expensive factory, there is no guarantee you will get the quality you desire. The factory will just laugh up their sleeve that someone actually took their high price, pocket the extra money, and give you the same crap quality as the cheap factory.

Harland — you are right, there is no guarantee. But let’s look at this the other way around. The lower the price, the higher the probability that the manufacturer does a bad job… That’s based on my experience, and it makes sense (the business from low-price customers are given no value in the long term). Does it fit with your experience?