There is a misconception in many people’s minds. They think there are many manufacturers in China & Vietnam capable of, and willing to, do a lot of the development work for a new product they think is promising.

That is true if you have millions of Facebook followers, you run a popular TV program, or Apple’s CEO declares they will distribute your product in his stores. In most cases, it is much harder, though.

5 product design questions you need to answer to be seen as a serious potential customer to suppliers in China/Vietnam/etc

If you want to be seen as a serious potential customer, you need:

- Realistic sales projections based on quantitative market research

- A relatively mature product design — I wrote about this before, but it worth re-iterating here.

Here are the 5 questions buyers need to answer to be in a position to go to potential suppliers with a mature product design…

1. Have you documented your requirements, and translated them into specifications?

At the very beginning, when determining what the concept is, it is fine to express the requirements as “it must feel like a premium product”, “it must be the fastest electrical bike on the market”, or “it must work fine in a Siberian winter”.

Now, what can a Chinese factory do with these? It is not specific enough to guide them, so it doesn’t help much and it can lead to many misunderstandings. It is also not specific enough to allow you to say “I told you about this but you didn’t respect it”, so in most cases, they see it as a positive and they will not try hard to help you define it better.

You need to define it as “On the visible areas defined in this graph, no blemishes more visible than on the boundary samples approved”, “Can ride at 55 mph for at least 30 min”, “No failures in a temperature of -20 degrees C for the first 2 years, based on the Arrhenius model, with a consumer’s risk of 5%”, or “must pass.

If you don’t do this, you count on the manufacturer’s subjective interpretation of your requirements, and you are exposed to them not complying with your requirements… and having no way to prove they are wrong.

2. Have you made the effort to understand the technical ins & outs of the technologies and materials to be used?

You may be totally focused on your customers’ needs. I get that. However, if you haven’t even fully figured how the product will work, will potential suppliers take you seriously? You should be telling them how it will work and getting their feedback.

Many projects need to incorporate a feasibility study and/or make a ‘proof of concept’. Don’t skip these steps if you are making a new product. You need to figure out how it will work before you start thinking of where to manufacture it!

3. Have you worked on the outer design of your product?

I explained this before in New Product Concept Brief: 5 Things Your Industrial Designer Needs To Know. But let’s be clear. This is not good.

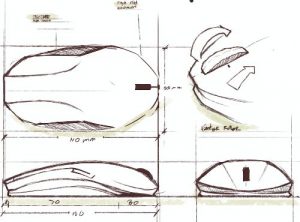

This is already better, but in most cases not ready yet to go and see a manufacturer.

This is much better, already. There are very clear shapes and dimensions, and it was input into a CAD software.

A complete design includes details of all sides (including the inside of the casing, for example), it specifies tolerances, it includes a priority system (some points are ‘critical to quality’), among others.

Some tooling often needs to be designed, fabricated, trialed, adjusted, and confirmed. Finalized product designs are just the start…

4. Have you started to select the key components, and to research & qualify their suppliers?

Some companies manage to put together a prototype with parts they purchased on Taobao or in other sources. The design is done around these parts. However, are you sure these parts’ suppliers can reach your quality level? If you haven’t audited them, you have no idea.

It is fine to do the first version of the Bill Of Materials (BOM) with unknown suppliers, but very early in the process, you need to confirm that the key components (e.g. enclosure, PCBA, battery …) come from solid sources. Otherwise, this may force you into a late redesign.

We have found that most Chinese OEMs do a bad job of sourcing their parts. Don’t leave that up to them.

5. Have you made progress on the engineering design?

If your product includes electronic parts (and more and more products do, these days), you need to make significant progress before going to discuss with a factory. Ideally, you get to the stage where you have finalized Gerber files and a list of parts.

On their side, the factory will probably need to prepare their on-line tests, their incoming QC tests, their jigs & tools (with maintenance & calibration instructions), work instructions and training for workers, and so on. Don’t think they can go directly into production…

But wait… you need to include the manufacturing constraints in your design, right?

Yes, of course.

And this is usually done through design reviews. And many engineers with serious manufacturing experience can do that for you.

In our guide about the NPI process, we made a short list of very common design issues:

- Example design issue 1 – Your current design will mean that you’re required to purchase complex components that simply don’t fit into your budget for the product as they’re too expensive.

- Example design issue 2 – The product design suggests that product assembly may be difficult or even impossible and that quality and/or cost would be greatly affected by trying to put it into production in its current state.

- Example design issue 3 – One of your product’s key features cannot be tested or validated in a factory. This could affect the quality or user experience.

- Example design issue 4 – Your design is missing the ability to cope with certain actions that end-users may put the product through, such as the ability to resist drops from a certain height or have parts moved in a direction that the design doesn’t account for.

Or maybe you really need to make an ODM or OEM such a partner from the start. We touched on selecting the right type of supplier in this article and discussed it on the podcast here.

Are you designing, or developing a new product that will be manufactured in China?

Sofeast has created An Importer’s Guide to New Product Manufacturing in China for entrepreneurs, hardware startups, and SMEs which gives you advance warning about the 3 most common pitfalls that can catch you out, and the best practices that the ‘large companies’ follow that YOU can adopt for a successful project.

It includes:

- The 3 deadly mistakes that will hurt your ability to manufacture a new product in China effectively

- Assessing if you’re China-ready

- How to define an informed strategy and a realistic plan

- How to structure your supply chain on a solid foundation

- How to set the right expectations from the start

- How to get the design and engineering right

Just hit the button below to get your copy (please note, this will direct you to my company Sofeast.com):

![Is Your New Product Design Ready for Manufacturing in China? [5 Questions] Is Your New Product Design Ready for Manufacturing in China? [5 Questions]](https://qualityinspection.org/wp-content/uploads/2020/11/IsYourNewProductDesignReadyforManufacturinginChina5Questions-300x158.jpg)