One recurring theme in this course is that you should not rely on the supplier’s salespeople.

Most of them would have been hired solely on the basis of their English skills. They are interpreters with very little technical knowledge, and they are not project managers.

There is actually no proper “project manager” in 99% of Chinese factories. So, who should manage the orders?

The bad news is, it’s the buyer’s job.

The good news is, it’s not necessarily much work.

Why the buyer should keep track of advances in production

In the sourcing phase and during new product development projects, the supplier has an interest in acting fast. He is “running after the order”.

The biggest source of delays, in these phases, is the buyer’s slow responses or imprecise information (unclear specifications, unclear feedback on samples…).

Once an order gets into production, though, the buyer should not simply wait for shipment. He should remain active and continue to communicate on a regular basis.

Chinese manufacturers are often late. For some of them, on-time deliveries are truly exceptional events. This is a fact you must count on.

So how do they communicate these delays to the buyer? If they see they will be 2 weeks late, will they announce it to their customer? Usually no, because they are afraid to get a response along the lines of “then you will pay for air freight”.

What they do instead, is wait until 1 week before the originally planned shipment date, and then announce a few days delay (even though they might still be waiting for some components, and production hasn’t started). Then they announce a few more days, then a few more days and so on.

A 2-week delay sounds quite bad. A 3-day delay is not that bad. But five 3-day delays equate to one 2-week delay.

Beware of a perverse effect. It unfolds this way: the customer is so pressed by time, he decides to skip the final inspection; the supplier notices it and thinks to himself “that’s great, there is no inspection when we don’t leave enough time for it”. Believe me, it will shape their future behavior!

Are penalties for late shipment realistic and applicable?

I see many buyers who write this term on their purchase order: “Penalty: 1 week late 5% of the order, 2 weeks late 10%…”.

But very few actually try to enforce it. They know the supplier probably makes less than 10% margin and will not accept to lose money on the order.

So, is this term pointless and useless? No! You should use penalties as a threat.

Your goal is to avoid two situations:

- Another buyer threatens to apply penalties and gets the priority over your order… Simply because you are playing it too nice with your supplier.

- The factory makes your goods in a rush, to avoid penalties, and ends up creating huge quality problems. (And, by the way, they will have a convenient excuse — you pushed them to hurry up, so really it is your fault.)

Does this sound like a fine line to walk? Sometimes the purchaser’s job is an art more than a science…

How professional importers track production

From my observations, some buyers manage to avoid most problems I described above. Here are a few things they do well:

- They check the factory’s capacity during the audit, to make sure they CAN make the order in a reasonable time frame.

- They add 2-3 weeks of padding, on top of the supplier’s forecast.

- For new products or new factories, they send an inspector during production. The idea is to check product quality, the production status, and whether the whole order is made in the approved manufacturing site.

- They use project management techniques to track the advances in production.

How to follow a project management approach

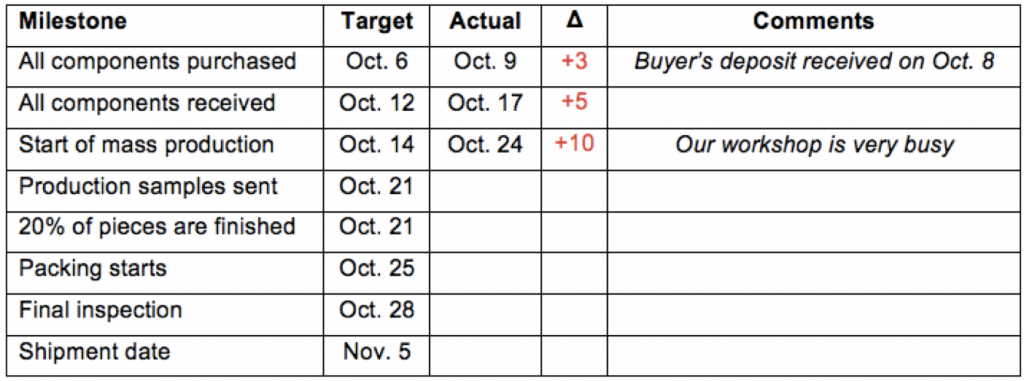

Here is a simple table that can be used by purchasers, for every order.

The problem is that, if you have several orders with several suppliers, the follow-up work quickly becomes too time-consuming. We do some project management work for some of our clients and it saves them much time.

In any case, remember — email is NOT a project management tool. And Skype/Wechat are even worse. There need to be other tools to structure followup and, when possible, also communication.

>> Move on to the next post in this series. Read it here: Sourcing from China 101, Part 9: Check Quality Early In Production <<

Are you trying to find a manufacturer in China who is well-suited to your needs and can also deliver on their promises?

Sofeast has developed 10 verification steps to help importers find the right manufacturing partner in China. They’re shared in this FREE eBook: “How To Find A Manufacturer In China: 10 Verification Steps.”

It covers:

- Background checks

- Manufacturing capabilities

- Quality system auditing

- Engineering resources

- Pricing, negotiation, & contracts

- …and much, much more

Just hit the button below to get your copy and put yourself in a great position to get better results from Chinese manufacturers who supply your products: