Many importers forget to specify how their products should be packed. And, every year, tons of products arriving from China are thrown away because they were not adequately protected. So, you need to think about how to protect shipments effectively with the right packaging!

Why packaging is a key concern for protection

Adequate packaging protects the goods in many ways during shipment. The bottom cartons might get crushed, some cartons might open up, products might get wet and become rusty or moldy, etc.

Importers face a tradeoff:

- A “lighter” packing will be cheaper, but will protect the products less effectively.

- A “very strong” packing will be more expensive and will (usually) represent higher volume & weight.

I made a list of elements that I think are critical:

1. Cardboard quality & thickness

Most buyers of consumer goods ask for strong corrugated cartons with double-wall (5 plies). This is really the minimum I’d advise for an export box.

The type of cardboard commonly used in China is of low quality and tends to suck humidity from the air very rapidly. You should take this into account and ask for thick cardboard.

Triple wall (7 plies) cartons are not unusual, especially when export cartons need to be large (example: more than 60cm in length). Smaller cartons always offer better protection.

This is what a double-wall looks like:

If you want to specify your requirements in further details, here are a few pointers:

- There are grades for cardboard quality. For example, B/C (B for the outside layer, and C for the inside layer) is common.

- There are many standards for free-fall carton drop tests, for stacking strength, for bursting strength, and so on. (Side note: we can help you define a testing plan if you are serious about defining a test plan that replicates the stresses a carton box may experience in your supply chain.)

2. Carton dryness

You don’t want wet cartons to be loaded in a container. Not only do you run the risk of receiving rusty/moldy products, but also the bottom row of cartons might get crushed under the weight they have to support.

Note that the inner packing, or the products themselves, might be humid. This is not unusual when production takes place in China, Vietnam, or India… Particularly during the rainy season.

There are a few solutions to this problem. Desiccants can be placed inside the cartons. Some products might have to go through an oven, or rest in a dry room (with air conditioning or with a dehydrator running), before packing.

3. Carton size

Cartons should be neither too full nor too empty.

In the photo below, the products need to pushed down before cartons can be closed. Sometimes manufacturers underestimate the size of their finished products, especially with garments. The result is often wrinkled clothing that needs to be ironed…

This is a reason why you need to ask for photos of the packing and give feedback to your supplier. (And here is another reason for that.)

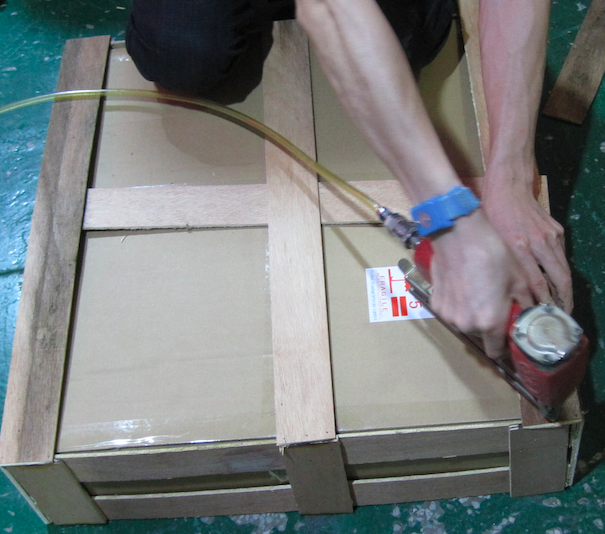

4. Bands and sealing

How to reduce the risk of cartons opening up during transportation?

For example by applying nylon bands around them, as shown below.

5. Pallets

The cartons will be better protected, and probably easier to move around, if they are on pallets and wrapped in plastic. Extra points if they are strapped as shown below.

You will also save a lot of time when emptying the container if you have the right equipment.

Note: if the products are shipped by air, you might want the factory to use plastic pallets (much lighter but more expensive) or even slip sheets (very light and flatter, but requires special equipment on both ends of the chain).

6. Extra protection along edges and corners

Sometimes wood protection is applied as below.

Note that this is also possible for protecting the retail packing inside the export carton, with cardboard instead of wood:

Recently, we also noticed some companies are using polystyrene corner protections like this:

For some products, just wood will be enough. Here is an example with electric insulators (outdoor products in strong porcelain):

By the way, this same product is typically packed differently for sales within China (see below). Make sure you don’t work with a small factory that exports for the first time, or this is what you might receive.

7. Inner cartons inside the export carton

One outer carton often contains several inner cartons, as below.

This solution offers double protection for the products.

8. Other ways to avoid unpleasant surprises

I have three other pieces of advice on how to protect shipments:

- Avoid LCL shipments by sea if you can (more information about LCL vs. FCL here).

- Give a loading plan to your supplier (heaviest items at the bottom)

- Appoint a quality assurance agency for a loading check.

Any other tips on how to protect shipments?

And do you think the main risk with packaging is damage to products? Or do you think more money is lost because of excessive packaging, as Kevin Howard believes?

Keep reading even more about packaging in these resources…

- How To Choose The Right Packaging To Protect Your Products? [Podcast]

- Why Packaging Is Important For Both Protection & Product Differentiation

- How to test the protection of your products during transport

- Plus – Remember to read our new Importer’s guide to 9 types of packaging over on Sofeast:

Just hit the image below to read it (no downloads required).

It includes plenty of information about how to protect shipments:

- 9 types of packaging (which are suitable for a handheld size product)

- Types of dunnage (interior packing)

- Electronics packaging

- Reusable packaging

- Next steps after products are packaged

Love this article. Packaging is always so overlooked. Just like anything, when it comes to packaging, you get what you pay for. Sometimes have a hard time understanding this.

Have you written any articles on loading plans that you mentioned? Or could you expand a little on this.

Cheers

Thanks Ronan. Yes, this article is in the “super useful” category 😉

No I don’t have much info on loading plans. But there are software solutions for that. These plans are useful when there are several types of products to load in one container.

A loading plan has 3 main objectives:

– To reduce damages, by placing the heavy & strong cartons at the bottom;

– To optimize space inside the container, so that more cartons can get in;

– To simplify the job of the warehouse staff at the receiving end (by not mixing the SKUs too much).

Very useful article, almost an Operating Procedure.

When we have a pallet like the one showed in point 5, we try not to keep flat the top of the package by putting on it one spare box so that it should prevent the forwader to lay above it other big packages.

We use it mainly by ROAD or LCL.

Thanks for the tip, Danilo. That’s smart.

A really good and practically helpful post, Renaud. To piggyback on what you said; the buyer needs to make double double sure they inform the supplier the EXPECTED packing quality and requirements. Don’t assume the supplier is going to give the best stuff but (and especially if it’s low-cost goods) assume they will use second-hand cartons with a bunch of Chinese characters written on them and taped up to fix previous water damage…a nightmare.

Also inform the supplier how long the cartons are supposed to last. For example: “we need packing that is going to last from factory to port to unloading to travel across the USA, etc…”.

Like most problems, this one is solvable with communication and then checking to make sure implemented.

Thanks Jacob. Yes sometimes they re-use cartons that are already beaten up, and it’s worthless.

Some buyers fail to communicate as you mention above. For example they could say “cartons need to go to a port, then do an 800 km trip in a truck, then are discharched in our warehouse, then are sent again on a truck, and they need to be perfect when the consumer gets one in their home”.

Very useful post Renaud, almost everything is covered. I usually depend on Gold Rich Park for packing services which provide me a quality and satisfactory service. As Jacob told we should inform them how longthe packing should last and they will do according to it.

Thanks Dennis.