So, you have found the product you wanted to re-sell on Alibaba or Global Sources. You feel the supplier will be fine. You had them audited and they seem reliable. They have the required certifications for selling on your market.

Like tens of thousands of other buyers of home appliances are, you will go ahead if you feel there is sufficient market demand for this product. However, there is one important thing you forgot.

How do these products behave in their users’ hands?

- Maybe you can confirm that another importer has been selling them for 3 years and hasn’t got many complaints. Great. If you are sure it’s the same product (same components, same processes…), you are probably safe.

- Otherwise, you will need to test the product for reliability. For all you know, the product might overheat and burn the user’s hair!! That can lead to an expensive recall and even more expensive lawsuits.

Let’s see what this means, in practice by examining a real example of a reliability testing plan for this kind of home appliance.

What is a common reliability testing plan for a home appliance?

Here’s an example of a reliability testing plan for an electronic hairbrush, a typical home appliance that you can see an example of at the top of this blog post.

Identify that the product works in different levels of temperature and humidity

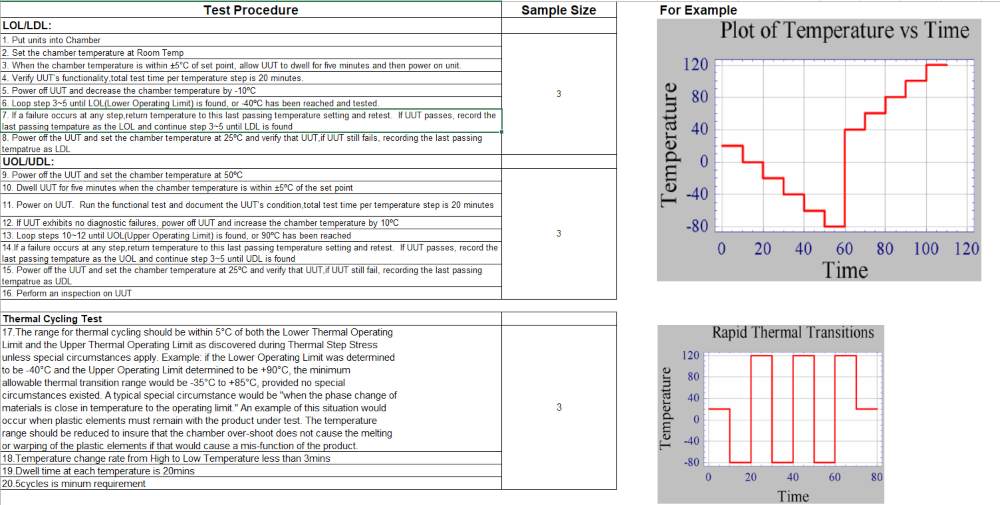

- HALT (Highly Accelerated Lifetime Testing) – Will the product fail early or cause safety issues? Here are the details of the HALT testing (reference standard: IEC60068):

- Humidity endurance testing (reference standard: IEC60068) – run at 40 deg C & 95% relative humidity for 48 hours. Do any functional, cosmetic, or safety issues appear?

Temperature measurement for handle and Surface

- Temperature measurement for handle and surface (reference standard: Simulate end-user actions) – Device at room temperature (max power) > Set several checkpoints and measure the handle temperature > Keep running at max power for 30 min.

Temperature control switch verify

- Verify the control switch is working (based on product specifications) – Simulate working model and get temperature to achieve 150 deg C. Check that the control switch will still work and turn the power off.

Drop and vibration tests to verify the structure

- Bare unit drop test (reference standard: Simulate end-user actions) – 2-meter drop height, 6 sides free drop on a concrete surface.

1) No functional and mechanical failures should be found after the test.

2) After the test, no signs of interference with the operation of safety features such as thermal cut-outs, overcurrent protection devices, or interlocks should be found. - Bare unit vibration test (reference standard: IEC60068) – 5Hz to 500Hz; PSD 2G^2/Hz; 3 axes, 30min/axis.

1) No functional and mechanical failures should be found after the test.

2) After the test, no signs of interference with the operation of safety features such as thermal cut-outs, overcurrent protection devices or interlocks should be found.

This type of testing costs a few thousand USD. Some buyers cut it down and only do HALT (Highly Accelerated Lifetime Testing), and maybe the manufacturer has the chambers to do it themselves. Other buyers are more risk-sensitive and will go for the full program.

Always remember, compliance is necessary but may not be sufficient. Ensuring reliability is very common on electrical and electronic products, but also on any type of product that, if it fails in the field, can cause serious damages.

Does this make sense for you? If you plan to sell tens of thousands of units, a reliability testing plan is an ABSOLUTE MUST.

P.S. you might also like this video where we explain reliability testing for electronics

Are you designing, or developing a new product that will be manufactured in China?

Sofeast has created An Importer’s Guide to New Product Manufacturing in China for entrepreneurs, hardware startups, and SMEs which gives you advance warning about the 3 most common pitfalls that can catch you out, and the best practices that the ‘large companies’ follow that YOU can adopt for a successful project.

It includes:

- The 3 deadly mistakes that will hurt your ability to manufacture a new product in China effectively

- Assessing if you’re China-ready

- How to define an informed strategy and a realistic plan

- How to structure your supply chain on a solid foundation

- How to set the right expectations from the start

- How to get the design and engineering right

Just hit the button below to get your copy (please note, this will direct you to my company Sofeast.com):

![Reliability Testing Plan For A Home Appliance in China [Example] Reliability Testing Plan For A Home Appliance in China [Example]](https://qualityinspection.org/wp-content/uploads/2020/05/ReliabilityTestingPlanForAHomeApplianceinChinaExample.jpg)