If you develop, manufacture, or distribute a product that has to perform its intended function for at least a certain duration, you probably need to do product reliability testing. Otherwise, you may have no idea how soon the product will … [Read more...]

Reliability Testing Plan For A Home Appliance (an Electronic Hairbrush) in China [Example]

So, you have found the product you wanted to re-sell on Alibaba or Global Sources. You feel the supplier will be fine. You had them audited and they seem reliable. They have the required certifications for selling on your market. Like … [Read more...]

Why Design Defects Are Behind Many Quality/Safety Issues

There is a tendency for inexperienced importers to blame their suppliers for all quality and safety issues that come up. However, in the situation where the buyer works with an OEM or a contract manufacturer, they share some (and usually … [Read more...]

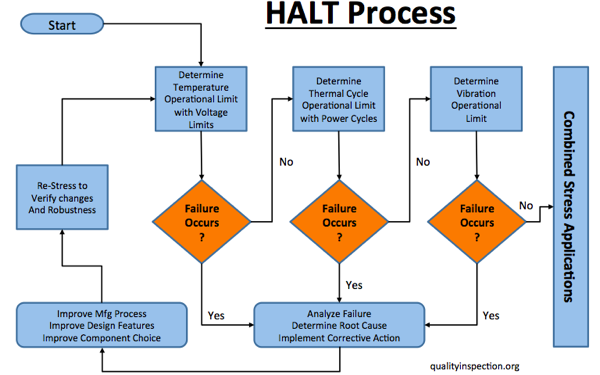

How HALT and HASS Can Help your Product Development Efforts

HALT and HASS are accelerated product reliability testing methods focused on finding potential defects in products. These acronyms stand for: HALT – Highly Accelerated Life Test HASS – Highly Accelerated Stress Screen If you are … [Read more...]

![Reliability Testing Plan For A Home Appliance in China [Example]](https://qualityinspection.org/wp-content/uploads/2020/05/ReliabilityTestingPlanForAHomeApplianceinChinaExample-960x627.jpg)