2020 has been a tough year for so many reasons: The COVID-19 pandemic, the continuing US/China trade war, the drive to exit China for some manufacturers, a global recession beginning, and more. But what effect has this had on the relationship between foreign importers and their Chinese suppliers?

To find out, we sent a survey to both our Sofeast and QualityInspection.org readers to assess the state of manufacturing in China in 2020. The results were eye-opening…

The State Of Manufacturing In China 2020

Listen to our discussion about the survey in this podcast episode:

Let’s take a look at the survey responses. I’ll also add my comments where appropriate:

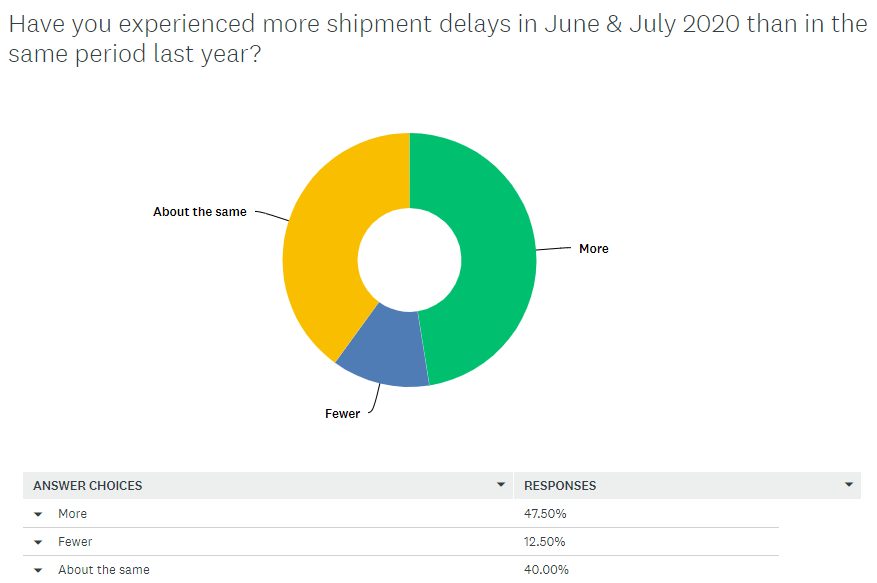

1. Are shipment delays more common?

The situation is better for a small minority (12.5%), but worse for 47.5% of the respondents. This is not surprising because of several factors:

- Some manufacturers reduced their number of operators & supervisors in the spring, when demand from the West crumbled, and they are ramping up in a more conservative fashion (not knowing if further lockdowns are coming).

- Logistics (especially air shipments) have been severely disrupted

- There might be a feeling for buyers that everything needs to be done urgently, because of the ever-changing situation. They might be more sensitive to delays than last year, and have the feeling they are more frequent.

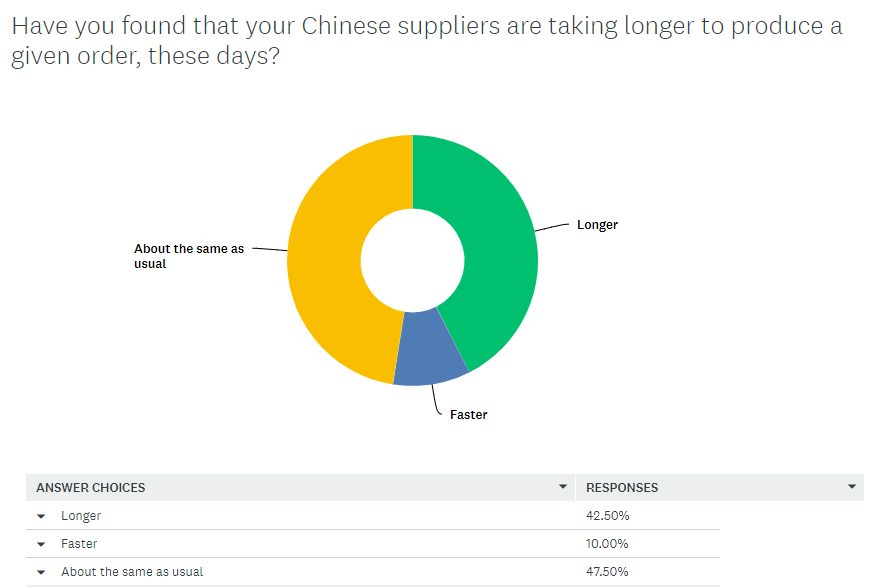

2. Does production take longer?

Same comments as above. This is in part due to lower capacity in many Chinese factories.

3. Have Chinese suppliers shuttered their factories?

This is interesting. I heard several people say their suppliers closed for 1 or 2 weeks because of a lack of work. This is clearly not just a few isolated cases.

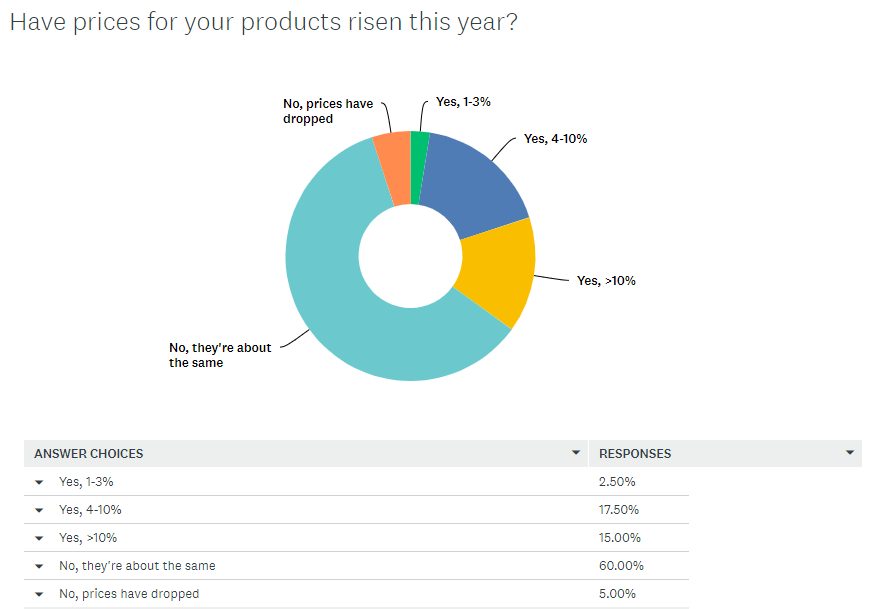

4. Have product prices risen?

No big surprises here. As a general rule, prices don’t drop in China, and there are few exceptions to that rule…

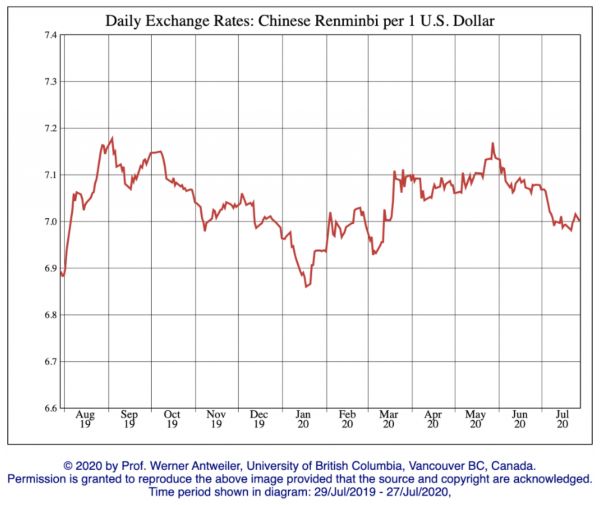

The RMB/USD rate hasn’t changed substantially.

For 15% of the respondents, prices went up more than 10% since last summer.

5. How about quality issues?

Here again, the trend is not good!

What has contributed to this?

- As I wrote in April in The Biggest Manufacturing Risk These Days: Short Term Focus, the people have lost sight of their long-term objectives. They fail to keep up their systems. They forget their hard-earned lessons.

- As manufacturing staff got laid off in spring, it affected those organizations’ abilities to do a good job consistently.

- In many product categories, the ‘rebound effect’ was brutal after lockdowns were lifted. Importers pushed their suppliers hard — “usually this takes 5 weeks, but can you make it in 2 or 3 weeks this time? We’ll be out of stock very soon!” When a job has to be rushed, quality suffers.

- Many buyers were generally sending their people to check the processes, the final product quality, etc. and these activities had to stop because of the travel bans. They can certainly be subcontracted to companies like ours, but the transition may not have been very smooth.

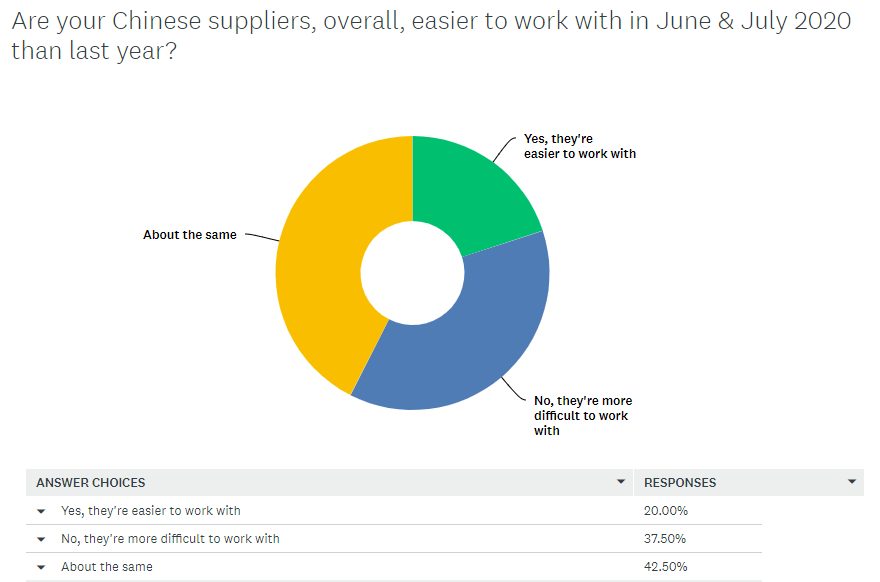

6. Has the ease of working with suppliers been impacted?

Some opposite trends are probably at work here:

- Some suppliers are more disorganized than before and may be upset by some of their foreign customers’ recent behaviors (e.g. freeze shipments and payments for more than a month, cancel some orders, etc.).

- Some suppliers see a sharp decline in their activity and need to make extra efforts to get some business.

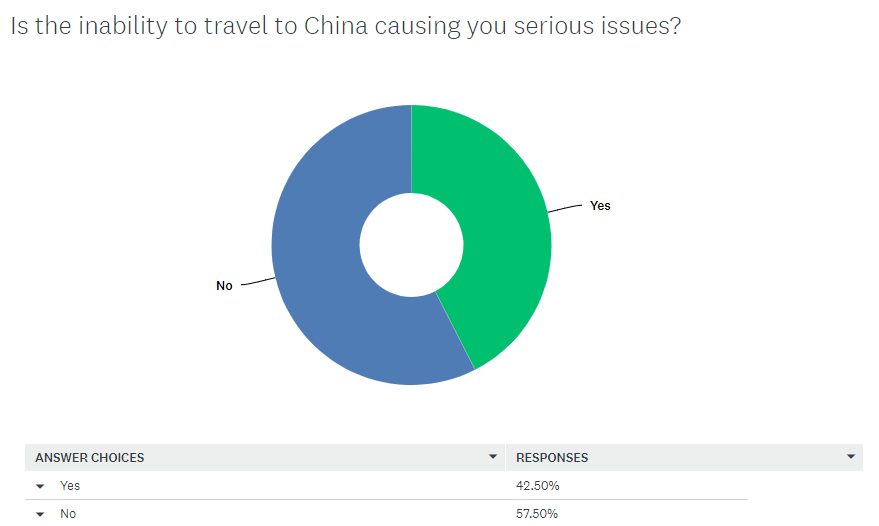

7. Is China closing its borders to foreigners causing you trouble?

This is interesting. I thought the “yes” camp would be above 50%. Many small buyers don’t come on the ground in China very often, and that might be a reason why “no” was the majority’s response.

Here are some of the responses about how not being able to travel to China has been problematic – perhaps some resonate with you, too?

Conclusion

Apart from the higher frequency of shipping delays and quality problems, our readers have remained fairly unscathed by the various global factors that can affect manufacturing in China.

Do these results tally with what you’ve experienced from your Chinese suppliers? Do let me know in the comments.

Are you designing, or developing a new product that will be manufactured in China?

Sofeast has created An Importer’s Guide to New Product Manufacturing in China for entrepreneurs, hardware startups, and SMEs which gives you advance warning about the 3 most common pitfalls that can catch you out, and the best practices that the ‘large companies’ follow that YOU can adopt for a successful project.

If you’ve decided to go it alone, this guide introduces a lot of the points you’ll need to consider in order to get to market.

It includes:

- The 3 deadly mistakes that will hurt your ability to manufacture a new product in China effectively

- Assessing if you’re China-ready

- How to define an informed strategy and a realistic plan

- How to structure your supply chain on a solid foundation

- How to set the right expectations from the start

- How to get the design and engineering right

Just hit the button below to get your copy (please note, this will direct you to my company Sofeast.com):