The Technology Readiness Levels product development framework was developed by NASA and is often used to gauge the progress of a new product launch project, especially during prototyping. It gives visibility and control over the process of going from concept to prototype that can be used as required. But is this a beneficial framework for manufacturers who are mass-producing products today?

Prefer listening to reading?

Where did the TRL framework originate?

Frameworks and tools like EVT, DVT, PVT, usually originate from a certain industry or company. In this case, from Motorola. Technology Readiness Levels, or TRL, is no different, as this framework originated from NASA in the 1970s. It was created as a framework to help them make sure that each stage of the development of a spacecraft was correct before they moved on to the next (and has been more recently adopted by the European Space Agency (ESA). TRL was not used for mass production at that time, because spacecraft were highly specialized, hand-built, items that were only made in small quantities. In many cases, parts or modules were outsourced to contractors like Lockheed Martin or Boeing who would be building them over long periods of time, so the TRL was used to check on their progress at each stage and release funding accordingly when validated. That’s why the development process was codified in this way, as it helped NASA to plan ahead for and control what was happening, have visibility over progress, and know when to release funding for these very lengthy and complex projects. (01:08)

The 9 Technology Readiness Levels

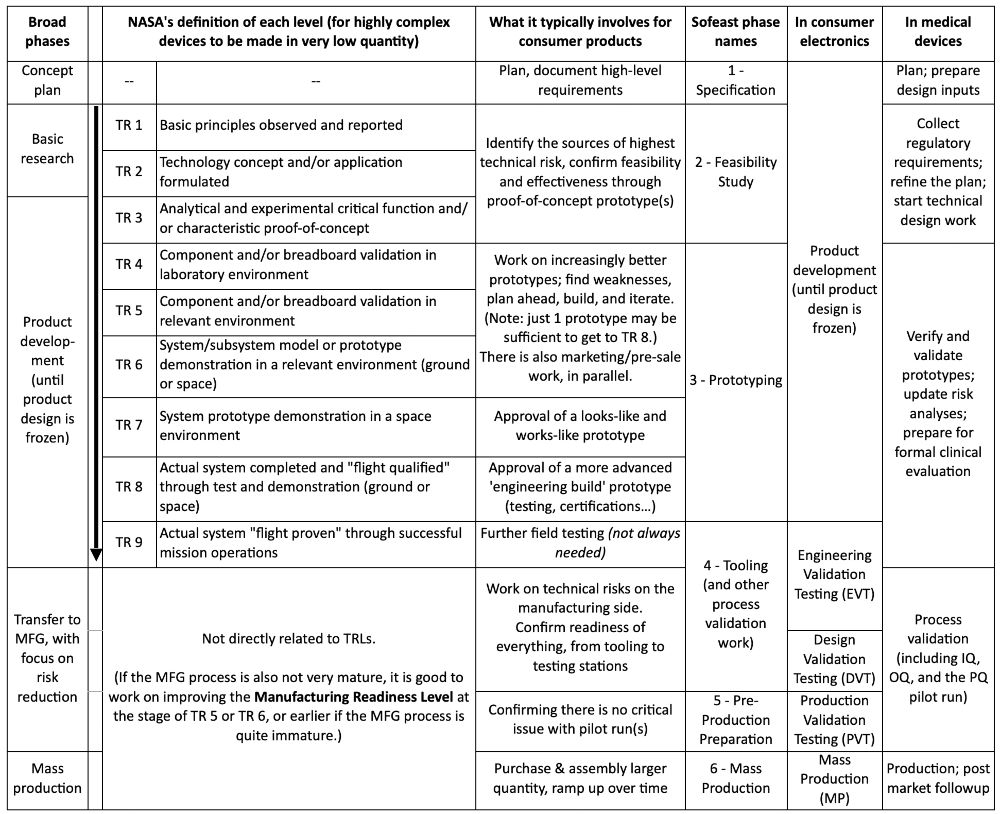

You can see the 9 original NASA TRL here (you can also see our corresponding NPI process phases next to them that incorporate the TRL and go further, and we’ll come on to that in more detail later):

Bear in mind that for the following levels, we are talking about spacecraft and their components, systems, etc, that are only made in small quantities throughout.

BASIC RESEARCH

1. Basic principles observed and reported – specifications, creating reports and documentation that support the product. Very specific on the directions of each element and component. We have to document design principles in a report that provides a signoff on the technology and your goals.

2. Technology concept and/or application formulated – looking at calculations and materials that may be used for building components. Looks more deeply at the technology behind your product concept. This backs up the initial report with calculations.

PRODUCT DEVELOPMENT (Until the design is frozen)

3. Analytical and experimental critical function and/or characteristic proof-of-concept – start working on a proof-of-concept prototype, particularly for validating the critical functions within the system itself. Breaking it down and looking at it experimentally, checking that critical functions are covered, looking at risks, and validating through a continuous proof-of-concept cycle. Prototype testing is done to provide you with some learnings about if the theory is working in practice.

4. Component and/or breadboard validation in a laboratory environment – the critical functions have been theorised and tested, so now, from an engineering point-of-view, this is when we start putting the components together properly in a simple way, which might be a prototype PCB or components on a breadboard, to see if we can get them to work and testing them in the lab together as more of a complete system. This may be just a sub-assembly or a scale model of a much larger assembly or system.

5. Component and/or breadboard validation in a relevant environment – now we move out of the controlled environment of the lab and validate components, subassemblies, etc, in the real environments they’re meant to be used in. This will not be a full prototype spacecraft at this point, we’re still validating individual modules, subassemblies and components.

6. System/subsystem model or prototype demonstration in a relevant environment (ground or space) – a scale or 1:1 prototype of the final product is made to demonstrate that it works and that the various systems communicate as required, etc. This level would probably require a lot of funding, therefore TRL 1-5 should be clear and approved by stakeholders first, and getting from TRL 5 to 6 could actually take years in real-time.

7. System prototype demonstration in a space environment – now the prototype needs to be tested in actual space, and every system, component, subsystem, etc, will be monitored and measured to check that they are working as expected.

8. Actual system completed and “flight qualified” through test and demonstration (ground or space) – stakeholders qualify a more final ‘engineering build’ of the spacecraft for flight by confirming that all of its systems etc have worked correctly and it is reaching performance standards.

9. Actual system “flight proven” through successful mission operations – all prior levels have been passed and the product is qualified and proven, so at this point, the spacecraft is built and will be used for real missions. The higher we get in the levels the more reliable the product is, as in TRL 7 and 8 it has been tested and used in space. (04:37)

Does this framework make sense in the context of mass production?

In its original NASA form, not really. If we look at cutting-edge 2023 rocket manufacturing by SpaceX and Blue Origin, they’re focusing on size and reusability, and the way they’re developing these products is how today’s manufacturers develop products for mass production because, at least in the case of SpaceX, the plan is to be manufacturing one rocket per month since a large number will be required for Musk’s planned mission/s to Mars. So the original TRL framework is limited and doesn’t even mention manufacturing in quantities, since the process was only ever meant to lead to a handful of hand-built spacecraft. (20:02)

26:09 – What is missing from the TRL in order to manufacture products in large quantities?

- Feasibility study – confirm on the technical side that your product concept is manufacturable at the right level of quality and reliability, will be compliant, etc, and that there actually is a market for it. This is all a part of the feasibility step and feeds into prototype phases when we answer the question, can and should we manufacture this product or component? Going straight to the prototype leads to risks for mass-produced products of producing a product that can’t be sold or is a danger for users, or one that you can never get into production at all. Certain industries and markets (such as automotive or medical devices) demand or have regulations requiring that you go through the feasibility process and confirm your production processes are capable at an early stage, in any case, so skipping it is really not an option (although consumer electronics doesn’t have these demands, hence the risk of skipping early NPI phases).

- Mindset – historically for most spacecraft it was only realistic to build maybe a handful of prototypes and final products due to the cost and because they were their own customer, but for today’s consumer electronics a large number of samples are needed for testing and validation in order to sell them in large quantities of millions in global markets while still being compliant and safe for consumers.

- Tooling – this is a large consideration and investment for electronics manufacturers because it needs to be capable of producing maybe millions of units, whereas in the TRL framework tooling isn’t really mentioned because it was one-and-done and they didn’t need to consider that it would need to be reused so often. Even SpaceX is only planning to make rockets in the thousands; that’s a minuscule number in mass production terms.

- Development of manufacturing and testing processes – DfX principles are missing from the TRL framework because designing products to be manufactured in large numbers, assembled efficiently, tested for quality and reliability where appropriate, etc, are required for mass production.

- Transfer to manufacturing – from TRL 7 onwards you need to be thinking about transferring to manufacturing (which NASA never needed to do) where the manufacturing process is worked on, kinks are ironed out, tooling and testing are ready, etc, so you know that the factory is ready to start work and ramp up the numbers.

Using the TRL framework alone puts you at risk of creating a great prototype, but not being able to get into production…a failure to launch, as it were. For that, you need a thorough NPI process that will provide gated step-by-step validation that shows that you’re going in the right direction and provides you with solid ground on which to go into mass production. (26:09)

Related content…

- Technology Readiness Levels: A Better Product Development Framework?

- The Design for X Approach: 12 Common Examples

- DFX: Product Design Optimizations You Should Consider [Podcast]