The rollercoaster has continued in 2021! After a difficult 2020 when the coronavirus pandemic first hit, it’s perhaps understandable that many of us might have hoped that things would settle down in 2021, however, since last year’s roundup in the top posts and videos of 2020 it’s been more of the same.

Supply chains have buckled, commodity and sea freight prices have gone through the roof, covid continues to rage (what variant are we even on now!?), and importers have numerous reasons to feel the strain. But there are reasons to be optimistic, too. A shopping boom has helped many companies get success after launching new products and the appetite for products made in Asia hasn’t let up.

Here are 10 top posts from 2021 that I’ve published and a couple of videos that you may have missed.

A few milestones from 2021

2021 was a busy year for myself and QualityInspection.org as I:

- Published another 115 posts to add to our total of over 1,330 totally free posts (up from 2020).

- Sent out over 100 email newsletters to our subscribers. You can subscribe here, too.

- Our podcast, ‘China Manufacturing Decoded’ is going from strength to strength with more than 11,000 downloads. Subscribe & listen to the episodes here.

- I have been mentioned in a number of news articles once again, such as from the South China Morning Post, Yahoo! Finance, InStyle, the WSJ and more. You can read my media interviews on this page over on my website Sofeast.com.

- Want to keep in touch? Join us on our LinkedIn page and subscribe to the QualityInspection.org YouTube channel which has lots of videos filled with tips to help you improve or understand certain topics better!

I trust that you have enjoyed plenty of the posts I’ve been writing on QualityInspection.org this year. Please always feel free to contact me if you have any requests for future content that you’d like me to write about, or even discuss on the podcast!

******

The 10 top manufacturing articles of 2021

Here are the 10 most popular posts published in 2021, from lower to higher engagement:

10. Supply Chain Risk Management: No, Toyota Doesn’t Always Do Just-In-Time

Automakers have endured a torrid time during 2021, as the global semiconductor shortage has led to production slowdowns and delays. The result? Fewer new cars being made, used car prices rocketing, and unwelcome delays for people with vehicles on order.

However, Toyota is much less impacted than its competitors, so what did they do right which their competitors got wrong?

I explain here.

9. Getting To Grips With Non-Recurring Engineering Costs (NRE) [Podcast]

In this episode of the podcast, we discuss Non-Recurring Engineering costs for manufacturers. As the name suggests, these costs are usually one-off and are what it takes to get your product into production. These costs include R&D costs, tooling costs, etc., and it’s important to get to grips with them as they have a great impact on your product’s sale price, as well as the feasibility of manufacturing it in the first place.

Listen to this podcast by clicking here.

8. How Bad Product Design Leads to Many Quality Issues

Most people see products of obviously poor quality and think the issues come from manufacturing, while, in fact, they most often come from bad product design!

All too often a manufacturer goes straight to putting a prototype together, without much thought about good design practices, strategic sourcing (picking the right components and the right suppliers), or reliability testing (confirming the product will not fail too easily or too early).

Read the post here.

7. Factory Management: the 4 Main Roles in the Quality Department

China, as a whole, has 35+ years of experience manufacturing products for export customers. They have accumulated a lot of experience.

However, foreign buyers are rather consistently shocked at the level of mismanagement that plagues their factories’ quality operations. And fixing it is not that hard.

In this article, I lay out what I see as the 4 basic roles that manufacturers need to fill in their quality department.

Read the article here.

6. How To Plan for Transferring Production To a New Factory: 45 Point Checklist

Many productions have been transferred to China over the past 25 years. Some are getting transferred out of China to places like Vietnam or Thailand these days.

And, of course, not all Chinese factories are doing a great job, so there is a great deal of switching from one to the next.

The problem is, some transfers are quite complex. There is the supplier management aspect, and there are all the technical details to get right. I have put together 45 point checklist that will help you think of those technical details.

Explore the checklist here.

5. List of testing laboratories in China

Many small buyers don’t know where their products can be laboratory tested in China. Actually, many of them don’t even know that they are responsible for compliance with their country’s safety regulations.

A handful of international groups have laboratory testing capabilities for the most common consumer goods in China, and I list them here in this post. In addition, I provide some guidance on why lab testing is so important, certifications, when testing is required or recommended, and more.

Read the list here.

4. Rising Raw Material Prices: What Strategy To Follow? (6 Approaches)

Raw materials costs have been increasing, partly due to the coronavirus pandemic’s effects, and some analysts predict a multi-year increase in the prices.

If those analysts are correct, it means the prices you will pay to have your products made are going to go up. If you do nothing, your margins will suffer or even disappear.

What are the strategies you can follow to combat increasing raw material prices? I tried to come up with a shortlist of 6 approaches that might make sense for you here.

3. The Design for X Approach: 12 Common Examples

The Design For X (or “Design for Excellence”) methodology lays out a number of design guidelines for reaching the product’s objectives. The idea is to review and improve the product & process design before the new product is manufactured.

Important questions for product designers include: “can it be made with mature processes?” and “can it be made within budget?” (a.k.a. Design for Manufacturing), “can it be assembled easily and without mistakes?” (a.k.a. Design for Assembly), etc.

Asking all of these questions in the initial product design, and then at every important milestone, is a way of detecting issues while they can still be addressed without excessive cost and delays.

Here are 12 common examples of the ‘Design for X Approach.’ Think about how these would improve your product design and lead to fewer issues when being produced, used by consumers, and more.

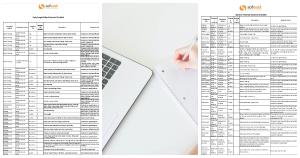

2. 3 Examples of Quality Inspection Checklists

Over the years, we have provided feedback to many clients on their product specification sheets and their inspection checklists.

Rather than a step-by-step guideline, the most useful is usually to provide them with a few real examples for different types of products.

Take a look at the quality inspection checklist examples here.

1. List of 12 Plastic injection mold fabrication companies in China

High-pressure plastic injection molding is one of the most common fabrication processes. Tens of thousands of factories in Ningbo, Shenzhen, and in many other places have at least a few presses running near-continuously.

If you develop your own product and it includes some custom plastic parts, you will probably need to invest in a mold. What should you know about this type of tooling, and what plastic injection mold fabrication companies in China can help you?

I’ve put together some tips about injection molding and a list of Chinese suppliers you could consider here.

Bonus: 7 Reasons To Switch To A New Chinese Manufacturer

This post provides some compelling reasons to switch from one Chinese supplier to a newer, better one if you’re not getting the results you need.

What should be sufficient to push you to develop a new supplier — to be kept as a backup, as a second source, or as the replacement to your current source?

Making a switch is not always easy. It takes preparation. That’s why I came up with a list of 7 reasons why you should switch to a new supplier in this post.

Top Videos from 2021

Here are a couple of videos that viewers particularly enjoyed this year:

How To Set Up A Receiving Inspection

How to select the right QMS for your requirements? (For manufacturers)

******

See you in 2022!

To every single one of you who has taken the time to read one of my posts, watch a video, listen to a podcast episode, or open an email ~ a massive thank you!

I’ll be back in 2022 to bring you tips, guidance, and commentary on the most important topics for importers with supply chains around Asia.

Best wishes and a Happy New Year! 🎉

Renaud

![Getting To Grips With Non-Recurring Engineering (NRE) Costs [Podcast] Getting To Grips With Non-Recurring Engineering (NRE) Costs [Podcast]](https://qualityinspection.org/wp-content/uploads/2021/04/GettingToGripsWithNon-RecurringEngineeringNRECostsPodcast-300x158.jpeg)