Recently I had an interesting conversation with the founder of a 4PL agency. They help some large companies reduce their costs along a supply chain.

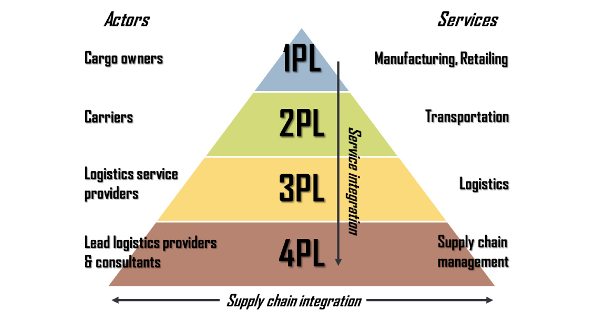

But first, what is a 4PL (4th party logistics services provider)?

You probably heard of “3PL”. These are carriers managing other carriers. Most importers work with a freight forwarder, which is a 3PL.

A “4PL” is a company that links the different parties in the supply chain, and sometimes also provides financing.

I found this nice graph on this page:

How do some 4PLs reduce the cost of a product?

Let’s take an example with 3 tiers of suppliers:

- The end customer (think big companies like BMW or HP)

- The first-tier supplier

- The second-tier supplier

- The raw material supplier

Here is a way it can work out:

- The end customer knows (roughly) what quantity they will buy over the next year, and engages a 4PL.

- The 4PL buys the raw material in large quantity and lock in a low price. This is possible since the quantity for the next year is known.

- The second-tier supplier gets a batch of raw material and buys it from the 4PL. It processes that batch and then sells it back to the 4PL.

- The 4PL arranges inspection at the second-tier supplier’s site (if it makes sense)

- If the second-tier supplier has a high scrap issue, or is inefficient in its use of resources, it is his problem. The 4PL only buys the “good” products.

- The same thing happens with the first-tier supplier.

Note that the 4PL can also arrange financing for the suppliers. Since they want to maintain their relationship with the end customer, and since the demand projections are relatively stable, the 4PL does not take large risks.

It seems to be used mostly in the electronics and the auto industries for components that are purchased in very high quantities. I have to say, I am not very familiar with this model.