If you start working with a new supplier that you haven’t visited or audited on-site, do you feel safe about your decision?

I have talked to many people in that situation, and they usually haven’t fully realized what they might be missing. So, that’s what I am going to cover in this article.

(I am discussing only audits of a factory’s quality system and processes, in the context of a company buying from a supplier located in China, Vietnam, India, and other low-cost countries.)

Here are 7 ways skipping an on-site audit can hurt your business.

1. It is a test of how serious the supplier is

If they are not interested in your business, they will refuse your request of sending an auditor. It’s better if you know about that upfront.

If they are secretive, they will also push back. That’s also a good thing. If you deal with a secretive supplier, you will never have transparency on the areas that matter to you, and that means you will not have control over your supply chain.

Also, if they have issues and you can’t send someone to analyze what is causing those issues, you will have to rely on their engineering capability and they ability to prevent recurrence in the future…

2. You won’t know what type of operation is involved

Are they a small operation? Are they midsize? Large?

Do they have immature (or inexistent) systems in place? Are they nicely structured (and much safer to work with)?

If you only look at their website, their pdf brochure, or what is written on their Alibaba profile, you may be far from the truth.

There is an enormous difference between a well-run factory and a poorly-run one. And it shows up clearly in the scores of audit reports.

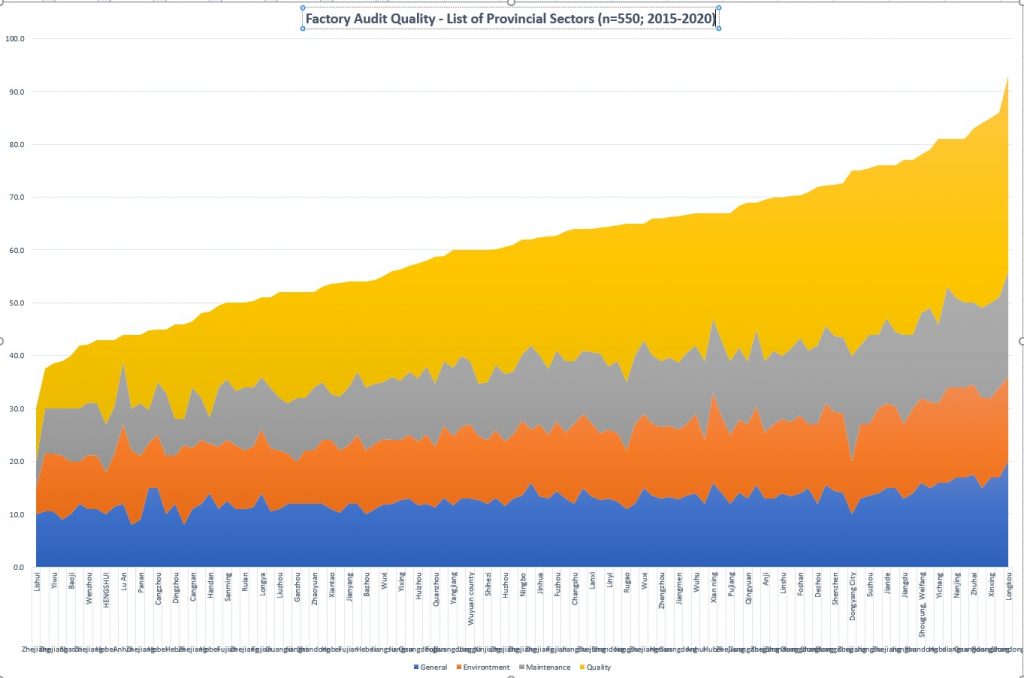

Let’s illustrate this in an instructive way. We plotted the average scores of some pas audits we have performed in various cities of China, and the gap between the best cities and the worst ones (including Yiwu, no surprise here) is quite obvious.

(Click on the image to enlarge it.)

3. You won’t know what processes the factory does in-house

When looking at the product you want your supplier to manufacture for you, you need to think about the critical components and critical process steps.

It’s all about recognizing the major risks and then having a plan to mitigate/control them.

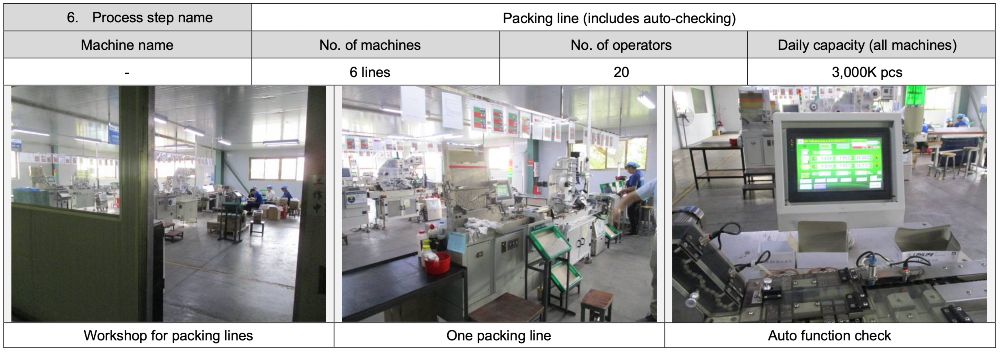

If you deal with a supplier that only does packing, or only does final assembly & packing, then the major risks may lie deeper in the supply chain, and you probably need to be aware of where the critical components/sub-assemblies come from. You might want to get those suppliers assessed, too.

4. You won’t know if their ISO 9001 certification is for real

It’s a fact that, in China, pretty much any factory can get ISO 9001 certified if they allocate a budget to it (as opposed to “set up a management system that complies with the standard’s requirements”). I wrote about this before in Hiring a Consultant to Prepare a Factory Audit.

And I wrote about some horrible systems we have observed in 10 Signs of a Bad ISO 9001 Implementation. A supplier is probably better off without all the nonsensical paperwork, actually.

5. You will not be able to predict whether their productions will be up to your quality standard

A low score in a quality system audit is not a good sign. And that’s not just my subjective opinion.

We have worked with Professor O’Connor from Monash University to see if there were insights to be gleaned from a look at past data of audits & inspections we did for our clients (based on a totally anonymised extract), and it is clear that a factory that tends to show a higher score on a factory audit also tends to perform better when it comes to product inspections.

(The study will be published later. The model is still being refined. But the relationship I mentioned above is significant, even with a confidence interval of 95%.)

6. You will not know if they maintain process discipline

I wrote about the importance of defining the processes and of ensuring sustained process discipline last year.

What we see these days is, overseas customers can’t come for a visit every 2-3 months as they used to, and many manufacturers tend to ‘relax’. Their ability to do a good job consistently slips. They drop the ball more and more often. If nobody rings the alarm bell and gets management to look into this, it can go on for a long time.

7. You will not be able to double-confirm if they really fixed issues at the root

Everything I wrote is also true of existing suppliers, to a certain extent. Their organization fluctuates over time, they gain and lose business, some key people leave, and you need to keep checking up on them.

This point (No. 7) is only about existing suppliers. Chances are, you suffered some issues, and you requested that they do the analysis and the changes necessary to prevent the recurrence of those issues. The problem is, without coming on-site, you can’t really be sure about the continued effectiveness of the countermeasures they put in place. That’s a good job for an auditor.

Some companies do this regularly, for example, every 2 months, as part of a layered process audit program. If you are buying large amounts of products from one supplier and you want to drive continual improvement there, that might be a great fit for you.

Conclusion

To conclude, just talking to a salesperson and reviewing samples is far from sufficient if you plan to send a lot of money to a supplier. You need to have an idea about the risks associated with relying on them for your productions.

If you want to know more about the most common types of audits, take a look at this video about selecting the right factory audits I made on Sofeast’s YouTube channel.